Description

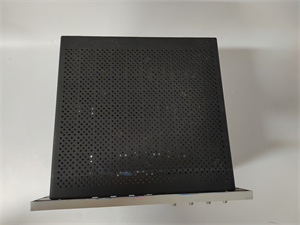

BENTLY NEVADA 3500/05-02-04-00-00-00 Rack Backplane Monitoring System

1. Product DescriptionThe

BENTLY NEVADA 3500/05-02-04-00-00-00 is a compact, high-performance

rack backplane monitoring system designed for industrial machinery protection. As part of the

BENTLY 3500 Series, it supports real-time vibration analysis, temperature monitoring, and fault detection, ensuring reliable operation of critical rotating equipment. This module integrates advanced signal processing algorithms to filter noise, calculate vibration parameters (e.g., crest factor), and trigger customizable alarms. Compatible with both full-size (14-slot) and mini (7-slot) racks, it is widely used in power plants, oil refineries, and manufacturing facilities to safeguard machinery and reduce downtime.

2. Technical Specifications

| Parameter |

Specification |

| Model |

3500/05-02-04-00-00-00 |

| Rack Type |

Mini (12-inch, 7 slots) |

| Mounting Options |

Panel/frame installation |

| Input Types |

Keyphasor signals from proximity probes |

| Channels |

2 (dual-channel design) |

| Input Voltage Range |

+0.8V to -21V (non-isolated) |

| Power Consumption |

3.2 W (nominal) |

| Temperature Range |

Operating: -40°C to +85°C |

| Dimensions |

304.8 mm × 24.4 mm × 163.1 mm (12 in × 0.96 in × 6.42 in) |

| Weight |

2.2 kg |

| Certifications |

CE, RoHS |

Bently 3500-05-02-04-00-00-00

3. Advantages and Features

- Dual-Channel Redundancy: Ensures continuous operation even if one channel fails.

- High Precision: Accurate vibration analysis with ±0.5% signal resolution.

- Fault Tolerance: Built-in diagnostics for slot ID verification and communication checks.

- Flexible Installation: Supports panel, frame, or wall mounting configurations.

- Energy Efficiency: Low power consumption reduces operational costs.

4. Application Areas and Use Cases

Industry Applications:

- Power Generation: Monitoring steam turbines and generators.

- Oil & Gas: Protecting pumps and compressors in offshore platforms.

- Manufacturing: Ensuring stable operation of machine tools and conveyor systems.

Case Study: A European steel plant implemented the 3500/05-02-04-00-00-00 to monitor rolling mill vibrations. Early detection of misalignment issues reduced maintenance costs by 25% and extended equipment lifespan.

5. Competitor Comparison

- Superior Signal Conditioning: Advanced filtering minimizes false alarms compared to basic modules.

- Dual-Channel Flexibility: Supports up to 8 keyphasor signals in paired configurations, surpassing single-channel alternatives.

- Compact Design: Mini-rack compatibility saves space in confined industrial environments.

Bently 3500-05-02-04-00-00-00

6. Selection Recommendations

- Rack Size: Choose the mini-rack for small systems or full-size for larger setups.

- Mounting Method: Opt for panel/frame installation based on accessibility requirements.

- Redundancy Needs: Pair with a backup module for critical applications.

7. Precautions

- Installation: Ensure secure insertion into the rack to avoid slot ID errors.

- Power Supply: Verify voltage compatibility (24–28 V DC) and use a redundant power setup for reliability.

- Maintenance: Regularly check cable connections and update firmware for optimal performance.

山西鑫业达国际贸易有限公司 offers

BENTLY NEVADA 3500/05-02-04-00-00-00 and comprehensive automation solutions. Visit

www.xydcontrol.com for technical support and product inquiries.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide