Description

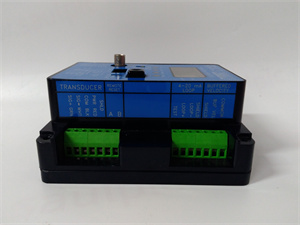

BENTLY NEVADA 1900/27 Single-Channel Vibration Monitor

1. Product DescriptionThe

BENTLY NEVADA 1900/27 is a compact, standalone vibration monitor designed for continuous health monitoring of rotating machinery in industries such as manufacturing, energy, and water treatment. As a single-channel solution, the

1900/27 supports compatible

BENTLY NEVADA 200150/190520 accelerometers and converts raw vibration signals into peak velocity units for real-time analysis. It features a built-in 4–20 mA output for integration with PLC/SCADA systems, along with configurable alarm relays for immediate fault notification. With dual power options (AC 85–264 V or DC 18–36 V) and Modbus RTU/RS485 connectivity, the

1900/27 balances flexibility and reliability in both critical and general-purpose applications.

2. Technical Specifications

| Parameter |

Specification |

| Model |

1900/27 |

| Input Type |

Single-channel vibration (accelerometer) |

| Sensor Compatibility |

BENTLY NEVADA 200150/190520 accelerometers |

| Input Sensitivity |

100 mV/g |

| Max. Acceleration |

20 g peak |

| Power Supply |

AC: 85–264 VAC, 47–440 Hz / DC: 18–36 VDC |

| Outputs |

4–20 mA analog, 2 alarm relays (SPST) |

| Communication |

Modbus RTU/RS485 |

| Dimensions |

17.8 cm × 12.7 cm × 8.9 cm |

| Weight |

0.68 kg |

Bently 1900/27

3. Advantages and Features

- Cost-Effective Protection: Single-channel design reduces upfront costs while maintaining BENTLY NEVADA’s reliability.

- Wide Power Range: AC/DC compatibility ensures suitability for diverse industrial environments.

- Modbus Integration: Seamless integration with digital control systems for centralized monitoring.

- TrendMaster 2000 Compatibility: Optional interface module (TIM) enables expansion into BENTLY’s advanced vibration analysis network.

- Local Display: Real-time vibration readings via optional remote display (up to 75 meters).

4. Application Areas and Use Cases

Industry Applications:

- Manufacturing: Motors, pumps, and conveyor systems.

- Energy: Small turbines and generators.

- Water/Wastewater: Centrifugal pumps and blowers.

Case Study: A food processing plant deployed the 1900/27 on packaging line motors. Early detection of imbalance via configurable alerts reduced unplanned downtime by 20%, saving $150K annually.

5. Competitor Comparison

- Superior Flexibility: Supports both AC/DC power and Modbus/analog outputs, unlike single-protocol alternatives.

- Compact Design: 30% smaller than legacy single-channel monitors, ideal for retrofitting.

- Scalability: Easy upgrade to BENTLY’s TrendMaster 2000 system for predictive maintenance.

Bently 1900/27

6. Selection Recommendations

- Channel Requirements: Opt for the 1900/27 for single-point monitoring; choose the 1900/65A for multi-channel needs.

- Power Type: Select AC or DC versions based on existing infrastructure.

- Integration Needs: Pair with TIM module if future expansion into TrendMaster 2000 is planned.

7. Precautions

- Sensor Wiring: Use shielded cables to prevent EMI interference.

- Alarm Thresholds: Calibrate setpoints according to machinery manufacturer guidelines.

- Environmental Conditions: Ensure operating temperature (0–50°C) and humidity (5–95% non-condensing) compliance.

山西鑫业达国际贸易有限公司 offers

BENTLY NEVADA 1900/27 and automation solutions. Visit

www.xydcontrol.com for technical support and product inquiries.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide