Description

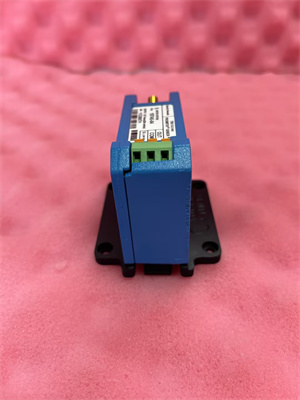

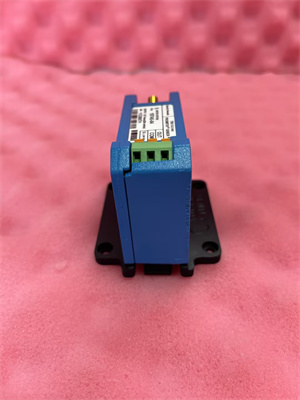

BENTLY 18745-04 Proximitor Sensor Product Documentation

1. Product DescriptionThe

BENTLY 18745-04 is a high-precision proximitor sensor designed for non-contact displacement and vibration monitoring in industrial machinery. As part of the Bently Nevada 7200 5mm/8mm series, this sensor measures static and dynamic distances between a probe tip and target surface, ensuring reliable performance in critical applications such as gas turbines, compressors, and pumps. The

18745-04 features a 5mm probe diameter and 9m cable length, offering a linear measurement range of 80 mils (2 mm) and compatibility with API 670 standards. It is widely used in rotating and reciprocating machinery to detect shaft misalignment, vibration, and axial movement.

2. Product Parameters

| Parameter |

Specification |

| Part Number |

18745-04 |

| Manufacturer |

Bently Nevada |

| Series |

7200 5mm/8mm Proximity Transducer |

| Probe Diameter |

5mm |

| Cable Length |

9m (29.5 ft) |

| Scale Factor |

200 mV/mil (8 V/mm) |

| Temperature Range |

-50°C to 100°C |

| Voltage Rating |

-18 to -24 VDC |

| Dimensions (HxWxD) |

8.13 cm x 6.12 cm x 6.35 cm |

| Compatibility |

Bently Nevada 3300/9000 Systems |

BENTLY 18745-04

3. Advantages and Features

- Non-Contact Measurement: Eliminates mechanical wear and ensures continuous operation.

- Wide Frequency Response: Supports 0 Hz (DC) to 10 kHz for both static and dynamic monitoring.

- High Precision: 80 mil linear range with ±1% accuracy.

- Robust Design: Operates in extreme temperatures (-50°C to 100°C) and harsh environments.

- Easy Integration: Works seamlessly with Bently Nevada 3300/9000 monitoring systems.

4. Application Areas and Case Studies

Industry Applications:

- Energy (gas/steam turbines, generators)

- Manufacturing (pumps, centrifuges)

- Petrochemical (compressors, motors)

Case Study:

A major energy plant reduced downtime by 30% using the BENTLY 18745-04 to monitor turbine shaft vibrations. The sensor’s real-time data enabled predictive maintenance, preventing costly failures.

5. Competitive Comparison

Compared to similar proximity sensors, the 18745-04 offers superior temperature resilience (-50°C vs. typical -40°C) and a longer cable length (9m vs. 5-7m), reducing installation complexity. Its API 670 compliance ensures compatibility with global safety standards.

BENTLY 18745-04

6. Selection Recommendations

- Compatibility: Verify integration with your existing Bently Nevada system (e.g., 3300/9000).

- Environment: Choose based on temperature and vibration requirements.

- Budget: Balance cost with long-term reliability (12-month warranty included).

7. Precautions

- Installation: Mount the probe perpendicular to the target surface and avoid electromagnetic interference.

- Maintenance: Periodically inspect cable connections and calibration if performance issues arise.

- Safety: Follow local electrical codes and isolate power before servicing.

山西鑫业达国际贸易有限公司 is your trusted partner for

BENTLY 18745-04 and automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide