Description

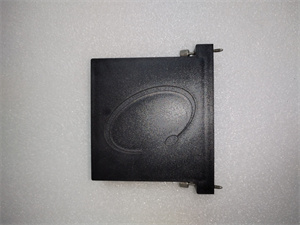

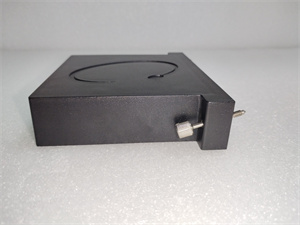

BENTLY NEVADA 170190-01E Dual Galvanic Isolator

1. Product DescriptionThe

BENTLY NEVADA 170190-01Eis a

dual galvanic isolator designed for hazardous area applications, supporting intrinsically safe transducer installations without external safety barriers. As part of the 1701/06 Field Monitor system, this module ensures reliable signal conditioning and isolation for radial vibration and thrust position measurements in critical machinery. With two channels, it accepts inputs from proximity probes and transducers, delivering accurate data while maintaining compliance with safety standards. Its compact design and robust construction make it ideal for environments such as oil refineries, chemical plants, and offshore platforms.

2. Technical Specifications

| Parameter |

Specification |

| Model |

170190-01E |

| Function |

Dual Galvanic Isolator |

| Channels |

2 channels |

| Input Types |

Proximity probe signals |

| Power Supply |

24 VDC ±10% |

| Isolation Rating |

2,500 VDC (galvanic isolation) |

| Mounting Options |

Panel or DIN rail mount |

| Dimensions |

263 mm × 58 mm × 28 mm |

| Weight |

4.3 kg |

| Certifications |

ATEX, IECEx (intrinsically safe) |

| Immunity |

High resistance to RFI/EMI |

BENTLY 170190-01E

3. Advantages and Features

- Intrinsic Safety Compliance: Eliminates the need for external barriers, reducing installation complexity in hazardous zones.

- Dual-Channel Isolation: Ensures signal integrity and protects against ground loops.

- Self-Test Functionality: Embedded diagnostics monitor system health and transducer connectivity.

- Flexible Mounting: Supports panel or DIN rail installation for space-efficient integration.

- Wide Temperature Range: Operates reliably in extreme conditions (-40°C to +85°C).

4. Application Areas and Use Cases

Industry Applications:

- Oil & Gas: Monitoring compressors, pumps, and turbines in explosive environments.

- Chemical Processing: Ensuring safety in reactor and agitator systems.

- Power Generation: Protecting generators and steam turbines in hazardous locations.

Case Study: A European chemical plant reduced downtime by 30% using the 170190-01E to monitor agitator vibrations. The module’s intrinsic safety features minimized installation costs while enabling continuous, safe operation.

5. Competitor Comparison

- Higher Channel Density: Supports two channels vs. single-channel alternatives.

- Integrated Isolation: Combines signal conditioning and galvanic isolation in a single unit.

- Global Compliance: Meets ATEX and IECEx standards, ensuring suitability for international projects.

BENTLY 170190-01E

6. Selection Recommendations

- Channel Requirements: Opt for the 170190-01E for basic dual-channel isolation; consider the 1701/15 for advanced vibration analysis.

- Hazardous Environments: Verify compliance with local safety regulations (e.g., ATEX zones 0/1/2).

- Space Constraints: Choose DIN rail mounting for compact control panels.

7. Precautions

- Installation: Follow wiring guidelines to prevent signal interference and ensure proper grounding.

- Calibration: Regularly validate sensor alignment and signal levels using BENTLY’s configuration tools.

- Maintenance: Replace modules if self-test alerts indicate faults or wear.

山西鑫业达国际贸易有限公司 offers

BENTLY NEVADA 170190-01E and automation solutions. Visit

www.xydcontrol.com for technical support and product inquiries.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide