Description

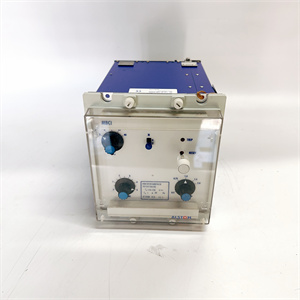

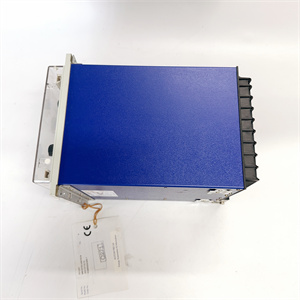

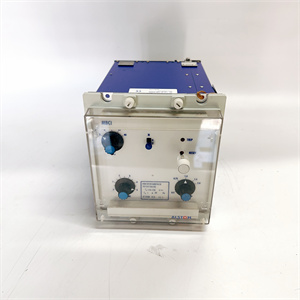

The ALSTOM MBCI01N1AB0761B is a high-performance PLC spare part designed to enhance the reliability and efficiency of industrial automation systems. As a key component from ALSTOM, a leader in power and automation solutions, the MBCI01N1AB0761B is engineered to meet the rigorous demands of complex control environments. This model serves as a critical interface module, facilitating seamless communication between various industrial devices and ensuring stable data transmission.

Ideal for maintaining and upgrading existing automation setups, the ALSTOM MBCI01N1AB0761B offers robust functionality that minimizes downtime and optimizes system performance. Its design prioritizes compatibility with a wide range of ALSTOM PLC systems, making it a versatile choice for industries relying on precision control. Whether used in new installations or as a replacement part, this module delivers consistent performance, ensuring smooth operation in challenging industrial settings.

| Parameter |

Specification |

| Model Number |

MBCI01N1AB0761B |

| Brand |

ALSTOM |

| Type |

PLC Interface Module |

| Voltage Range |

24V DC ±10% |

| Current Consumption |

≤500mA at full load |

| Communication Interfaces |

Ethernet (10/100Mbps), RS-485, Profibus DP |

| Operating Temperature |

-20°C to +60°C |

| Storage Temperature |

-40°C to +85°C |

| Dimensions (W×H×D) |

100mm × 150mm × 50mm |

| Weight |

0.5kg |

| Compatibility |

ALSTOM PLC series, select third-party systems |

MBCI01N1AB0761B

The ALSTOM MBCI01N1AB0761B stands out for its exceptional reliability, with a mean time between failures (MTBF) exceeding 100,000 hours, ensuring long-term operational stability. Its dual communication interfaces allow for flexible integration with both modern Ethernet-based systems and legacy industrial networks, reducing the need for additional adapters. The module also features advanced error-checking capabilities, which automatically detect and correct data transmission issues, minimizing signal loss and improving overall system accuracy.

One of its key strengths is its rugged construction, designed to withstand harsh industrial environments with high levels of electromagnetic interference (EMI) and mechanical vibration. This durability makes it suitable for use in demanding settings where equipment exposure to dust, moisture, or temperature fluctuations is common.

The ALSTOM MBCI01N1AB0761B is widely used in industries such as energy production, manufacturing, and transportation. It is particularly well-suited for applications requiring precise control and reliable communication, including power plant automation, conveyor systems, and process control in chemical plants.

Case Study: A major manufacturing facility in Europe integrated the MBCI01N1AB0761B into its aging production line to bridge communication between outdated machinery and a new centralized control system. The module’s multi-protocol support allowed seamless data exchange, reducing setup time by 30% and improving production line efficiency by 15%. The plant reported no communication failures during the first year of use, highlighting the module’s reliability in real-world industrial conditions.

Compared to similar interface modules on the market, the

ALSTOM MBCI01N1AB0761B offers superior compatibility with legacy systems while supporting modern communication protocols, eliminating the need for frequent hardware upgrades. Its robust thermal design ensures stable performance at extreme temperatures, outperforming many alternatives that struggle with harsh environments. Additionally, the module’s intuitive configuration interface reduces installation complexity, saving both time and technical resources during setup.

MBCI01N1AB0761B

When selecting the ALSTOM MBCI01N1AB0761B, consider the following factors:

- Compatibility: Ensure it aligns with your existing PLC system architecture, particularly if integrating with ALSTOM or compatible third-party devices.

- Environment: Verify that the module’s temperature and durability specifications match your operational conditions, especially for high-EMI or harsh industrial settings.

- Budget: While the module offers premium reliability, compare its features with your specific needs to balance performance and cost effectively.

- Installation: Always power down the system before installing or replacing the module to avoid electrical damage. Use anti-static wrist straps to prevent electrostatic discharge (ESD) during handling.

- Maintenance: Regularly clean the module’s vents to prevent dust accumulation and ensure proper heat dissipation. Schedule periodic firmware updates to benefit from the latest performance optimizations.

- Safety: Follow local electrical codes and safety standards when wiring the module, especially for high-voltage applications.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide