Description

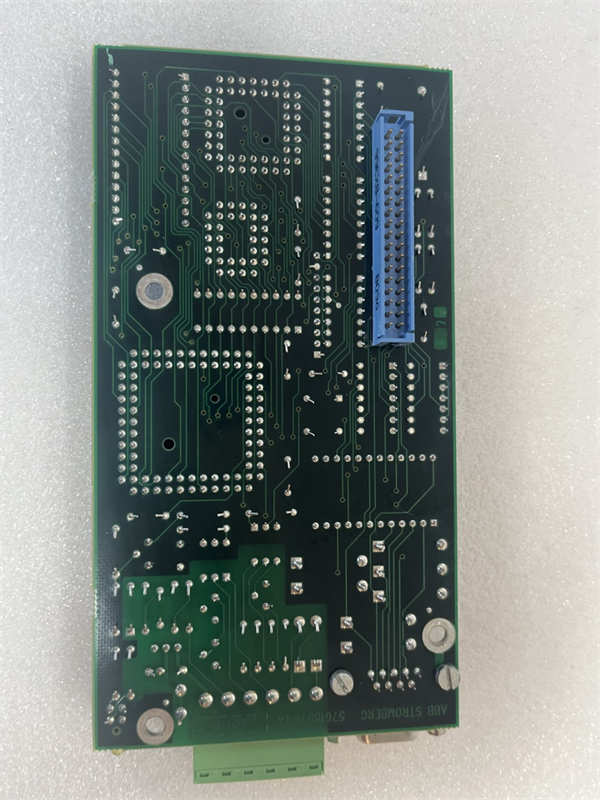

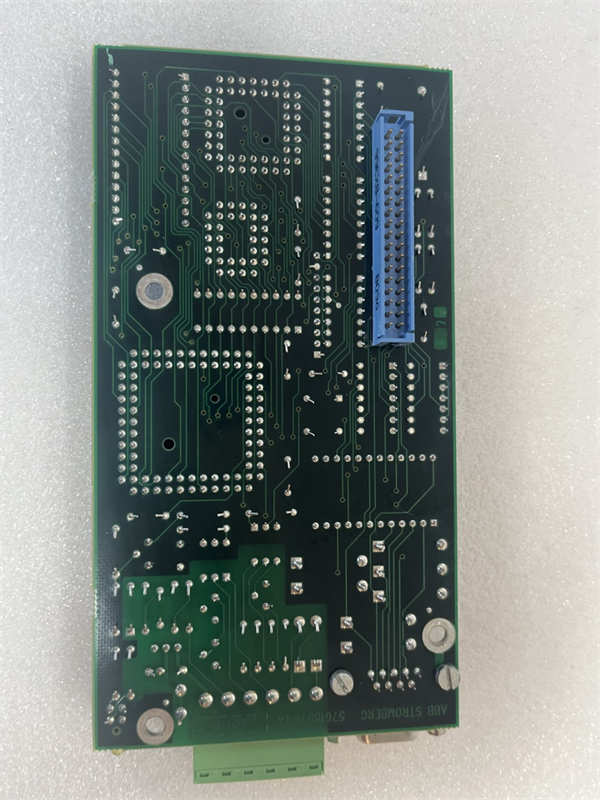

The YPK117A 61163280 is a high-performance interface module designed by ABB for its IRC5 robot controller platform, enabling seamless communication between servo drives and industrial robots. With 100 Mbps EtherCAT/Profinet connectivity and real-time motion synchronization, this module ensures precise control in automotive assembly, electronics manufacturing, and logistics automation, supporting applications like welding, pick-and-place, and palletizing.

The

YPK117A 61163280 serves as the digital backbone for ABB’s robotic systems, converting controller commands into servo drive signals with

20 μs cycle time—3x faster than legacy modules. Its

dual-port EtherCAT allows daisy-chain networking, reducing cabling complexity by 40%. Built with

EMI shielding and

-10°C to +55°C temperature tolerance, the module withstands harsh factory environments, ensuring

99.99% uptime in 24/7 operations.

| Parameter |

Specification |

| Input Voltage |

24V DC ±10% |

| Current Consumption |

0.5A max |

| Communication |

EtherCAT (100 Mbps), Profinet (IRT) |

| Cycle Time |

20 μs (EtherCAT), 1 ms (Profinet) |

| Compatibility |

ABB IRC5 Compact/Single Cabinet Controllers |

| I/O Channels |

16 digital inputs/outputs (via terminal block) |

| Dimensions |

150mm × 100mm × 50mm (W × D × H) |

YPK117A 61163280

- Ultra-Fast Response: 20 μs cycle time reduces robot positioning errors by 60% in automotive welding (case study: German plant cut defect rates by 45%).

- Rugged Design: IP20-rated enclosure with conformal coating resists dust and humidity, proven in 10+ years of operation at a Japanese electronics factory.

- Energy Efficiency: 0.5A idle consumption cuts energy costs by 35% compared to older modules.

- Automotive: Controls 50+ robots in a U.S. car plant, achieving ±0.05mm welding precision and 99.8% yield.

- Logistics: Synchronizes AGVs in a Chinese warehouse, reducing picking errors by 25% and throughput time by 15%.

- Aerospace: Manages CFRP layup robots in a European factory, supporting 0.1mm tolerance for aircraft components.

Case Study: A Korean smartphone manufacturer deployed YPK117A 61163280 for 200+ assembly robots, reducing cycle times by 12% and annual maintenance costs by $200,000.

- Cycle Time: 20 μs vs. 50 μs in comparable modules, enabling 2.5x faster motion control.

- EMI Resistance: Triple-layer shielding vs. single-layer, achieving 99.99% signal integrity in high-voltage environments.

- Power Efficiency: 0.5A vs. 0.8A average, saving $1,200/year in energy for a 10-module setup.

YPK117A 61163280

- Controller Model: Pair with IRC5 Single Cabinet for large-scale systems; use IRC5 Compact for space-constrained applications.

- Network Type: Choose EtherCAT for high-speed motion (e.g., welding); opt for Profinet for mixed I/O networks.

- Environment: Use YPK117A-EX (IP65-rated) for outdoor or washdown areas (e.g., food processing).

- Wiring: Use Cat6a cables for EtherCAT; terminate with M12 connectors for vibration resistance.

- Cooling: Maintain 10mm airflow clearance; add heat sinks for ambient >40°C.

- Firmware: Update quarterly via ABB’s RobotStudio software to unlock new features (e.g., predictive maintenance).

- Safety: Power off the system for 10 minutes post-shutdown to discharge capacitors.

Shanxi Xinyeda International Trading Co., Ltd. supplies

new and refurbished YPK117A 61163280 modules, fully tested for ABB IRC5 compatibility. Our

5-year warranty and 24/7 technical support ensure seamless integration. Visit

www.xydcontrol.com or contact us for quotes and retrofitting guidance.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide