Description

The

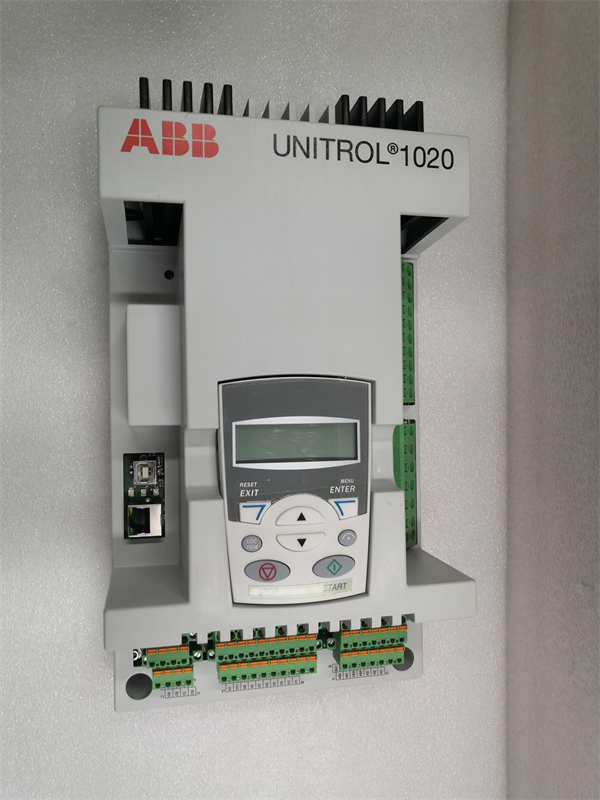

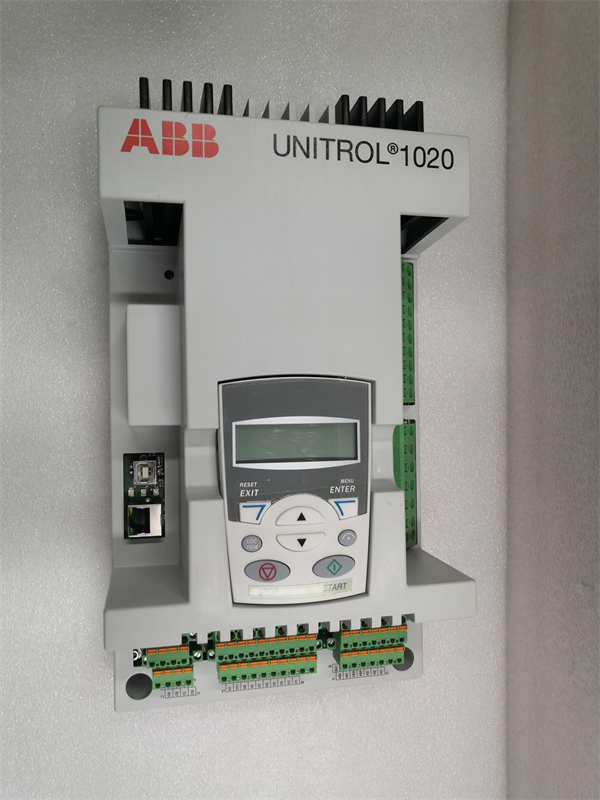

ABB UNITROL 1020 is a high-performance excitation controller designed to ensure stable and efficient operation of synchronous generators in various industrial and power generation applications. As a key component of ABB’s UNITROL series, the

UNITROL 1020 is engineered to regulate the excitation current of generators, maintaining optimal voltage control and reactive power management. This model is widely recognized for its reliability, precision, and adaptability, making it a preferred choice for industries that demand consistent power quality and system stability.

The UNITROL 1020 serves as the core of generator excitation systems, enabling seamless integration with both new and existing setups. Its primary functions include voltage regulation, automatic synchronization, and protection against overloads or abnormal operating conditions. By maintaining precise control over the generator’s excitation, the controller enhances the overall efficiency of power generation processes, reduces energy losses, and minimizes the risk of system disruptions.

| Parameter |

Specification |

| Input Voltage Range |

100–240 V AC, 50/60 Hz |

| Output Current Capacity |

0–10 A (continuous), 15 A (peak) |

| Voltage Regulation Accuracy |

≤±0.5% of rated voltage |

| Frequency Range |

45–65 Hz |

| Communication Interfaces |

RS-485, Ethernet (Modbus TCP/IP) |

| Control Modes |

Automatic voltage control (AVR), Manual current control |

| Operating Temperature |

-20°C to +55°C (with derating above +40°C) |

| Protection Features |

Overvoltage, undervoltage, overcurrent, thermal overload |

UNITROL 1020

The UNITROL 1020 stands out for its advanced digital control algorithm, which provides rapid response to voltage fluctuations and ensures stable operation even in challenging environments. Its modular design allows for easy installation and maintenance, reducing downtime and service costs. The controller also incorporates energy-efficient components, contributing to lower operational expenses over its lifespan.

One of its key features is the adaptive load compensation, which dynamically adjusts the excitation current based on the generator’s load conditions, improving power factor and system stability. The UNITROL 1020 also supports remote monitoring and configuration via its Ethernet interface, enabling real-time diagnostics and proactive maintenance to prevent unexpected failures.

The UNITROL 1020 is ideally suited for use in power plants, industrial generators, and renewable energy systems such as wind and hydro turbines. It is commonly applied in scenarios where precise voltage regulation and reliable reactive power control are critical, including standalone generator setups and grid-connected power systems.

Case Study: A medium-sized industrial plant in Europe integrated the UNITROL 1020 into its backup generator system to address recurring voltage instability issues. The controller’s fast response time and adaptive load management reduced voltage fluctuations by 90%, ensuring uninterrupted power supply during grid outages. The plant also reported a 15% improvement in energy efficiency due to the controller’s optimized excitation control.

Compared to similar excitation controllers on the market, the UNITROL 1020 distinguishes itself through its balanced combination of precision, durability, and ease of integration. It offers a wider operating temperature range and more robust protection features, making it suitable for harsh industrial environments. The controller’s advanced communication capabilities and user-friendly interface also simplify system integration and remote management, setting it apart from less digitally equipped alternatives.

UNITROL 1020

When selecting the UNITROL 1020, consider the following factors:

- Compatibility: Ensure the controller’s input/output specifications match your generator’s rated voltage and current requirements.

- Environment: Verify that the operating temperature and humidity range align with your installation site’s conditions.

- System Integration: Assess the need for specific communication protocols (e.g., Modbus TCP/IP) to connect with your plant’s monitoring systems.

- Budget: Balance the controller’s advanced features with your project’s cost requirements, noting its long-term efficiency gains.

- Installation: Always disconnect power before installing or servicing the UNITROL 1020 and follow all electrical safety standards.

- Calibration: Perform initial calibration and regular system checks to ensure accurate voltage regulation.

- Software Updates: Keep the controller’s firmware up to date to benefit from the latest performance improvements and bug fixes.

- Environmental Protection: Use appropriate enclosures or protective measures if installing the controller in dusty, humid, or corrosive environments.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide PFEA112-65 3BSE030369R65 and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide