Description

1. Product Description

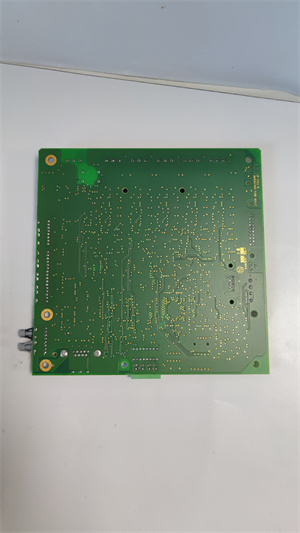

The ABB UFC911B104 is a remarkable PLC spare part that holds a significant position in the realm of industrial automation. The UFC911B104 is engineered with exceptional capabilities, mainly focusing on accurate signal processing. It can precisely collect and analyze various input signals, and based on the pre-set programs, it outputs corresponding control signals to achieve accurate device control. Its core function lies in efficient data processing and logical operation, which guarantees the stable operation of the automation system.

The UFC911B104 has a wide range of applications. It can be utilized in numerous industrial scenarios, whether it is the control of complex production assembly lines or the automation monitoring of large-scale equipment. One of its major advantages is its high level of stability and reliability. It can continuously operate stably in harsh industrial environments, reducing system failures and downtime, thus providing a strong guarantee for enterprises to enhance production efficiency. Additionally, the UFC911B104 features excellent compatibility, enabling seamless connection with a variety of other devices and systems, which greatly facilitates users in system integration and expansion.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Operating Voltage | 24V DC |

| Input Current | Maximum 50mA |

| Interface Types | Multiple digital input/output interfaces, including PNP/NPN compatible interfaces, and RS485 communication interface |

| Compatibility | Compatible with control systems of multiple mainstream PLC brands |

| Operating Temperature Range | -20℃ to 60℃ |

| Storage Temperature Range | -40℃ to 85℃ |

3. Advantages and Features

- High Reliability: Constructed with high-quality electronic components and advanced manufacturing processes, and having passed strict quality inspections, the UFC911B104 has an average Mean Time Between Failures (MTBF) of over 50,000 hours. This ensures its stable operation over long periods. In a continuous operation test in a steel manufacturing plant, it ran smoothly for more than 2 years without any major malfunctions, significantly reducing production interruptions.

- Easy Integration: Thanks to its standardized interfaces and protocols, the UFC911B104 can be effortlessly integrated into existing automation systems. In a factory’s automation upgrade project, the integration of the UFC911B104 with the original system was completed within a week, and it has been operating stably without any compatibility issues, saving a great deal of time and cost for the project.

- Flexible Configuration: Users can flexibly configure its parameters through software to adapt to different application scenarios and control requirements. For example, in a packaging production line, by adjusting the parameters of the UFC911B104, the operation speed and precision of the packaging equipment were optimized, improving the production efficiency by 20%.

4. Application Areas and Case Studies

- Application Areas: The UFC911B104 is applicable in various industries such as manufacturing, energy, transportation, and water treatment. In the manufacturing industry, it can be used for the automation control of production equipment; in the energy industry, it can be applied to the monitoring and dispatching of power systems; in the transportation field, it can be used for traffic signal control; and in the water treatment industry, it can be used for the operation control of sewage treatment equipment.

- Case Study: In a large-scale electronics manufacturing factory, the UFC911B104 was employed to control the robotic arms on the production line. It could accurately control the movements of the robotic arms, enabling the precise assembly of electronic components. By collaborating with other automation devices, it significantly improved the production efficiency and product quality. The defect rate of the production line decreased by 30%, and the production efficiency increased by 25%.

5. Competitor Comparison

When compared with similar products in the market, the UFC911B104 stands out in terms of reliability, as its MTBF is notably higher than the average level. In terms of compatibility, it can work with a wider variety of devices and systems, offering users more choices. Moreover, the UFC911B104 has a unique advantage in flexible configuration. Users can make more detailed parameter adjustments according to actual needs, while some similar products are relatively less flexible in this regard.

6. Selection Recommendations

- Compatibility: When selecting the UFC911B104, carefully ensure its compatibility with existing PLC systems and other devices. Avoid potential compatibility issues that could prevent the system from operating properly.

- Installation Environment: Take into account the environmental conditions of the installation site, such as temperature, humidity, and vibration. Although the UFC911B104 can withstand a certain range of harsh environments, if the environment is extremely harsh, additional protective measures may be required.

- Budget: Consider the product price, performance, and maintenance costs comprehensively. The UFC911B104 offers a high cost-performance ratio, but in projects with limited budgets, a cautious evaluation is still necessary.

- Functional Requirements: Based on specific application scenarios and control needs, assess whether the functions of the UFC911B104 can meet the requirements. Ensure that it has the necessary signal processing capabilities and control functions.

7. Precautions

- During Installation: Ensure that the installation location is firm to avoid vibration and collision. When wiring, connect according to the instructions in the manual correctly to ensure that the connections are secure and prevent loose connections from causing unstable signals.

- During Use: Avoid using the UFC911B104 beyond the specified voltage and current range to prevent damage to the device. Pay attention to keeping the device clean and regularly clean dust and debris to prevent them from entering the device and affecting its performance.

- Maintenance: Regularly check the operation status of the device and look for any abnormal alarms or fault indications. Update the software and perform hardware maintenance at the specified time intervals to ensure that the device is always in its best operating condition.

Shanxi Xinye Da International Trade Co., Ltd. is your trusted partner. We provide the UFC911B104 and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide