Description

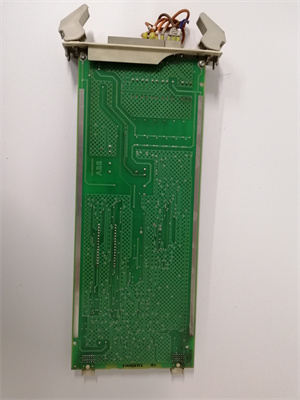

The

ABB TC520 is a high-performance

System Status Collector designed for seamless integration with ABB’s Advant controllers (AC450 and AC460) in industrial automation systems. This module serves as a critical component for real-time monitoring and data collection, ensuring optimal system health and operational efficiency. Engineered with robust metal casing and advanced error-correction mechanisms, the

TC520 withstands harsh environments, including extreme temperatures (-40°C to +70°C) and electromagnetic interference (EMI), making it ideal for manufacturing, energy, and process control industries.

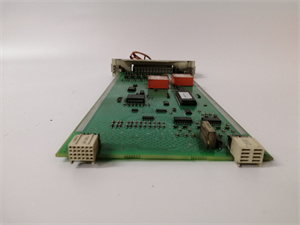

Key functionalities include real-time status monitoring of controller subracks, distributed data transmission via a dedicated serial link, and synchronization of system clock signals. The TC520 supports multiple communication protocols, such as Modbus TCP/IP, enabling compatibility with both legacy and modern control systems. Its autonomous operation ensures continuous data collection regardless of user intervention, while the hot-swap capability minimizes downtime during maintenance.

| Parameter |

Details |

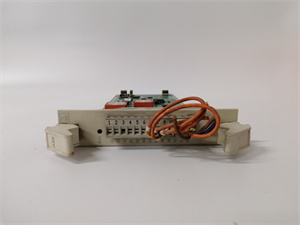

| Voltage Supply |

DC 24V ±10% |

| Power Consumption |

≤15W |

| Communication Interfaces |

Modbus TCP/IP, Serial Link (Transmit-Only) |

| Operating Temperature |

-40°C to +70°C |

| Storage Temperature |

-40°C to +85°C |

| Compatibility |

ABB Advant AC450/AC460 controllers |

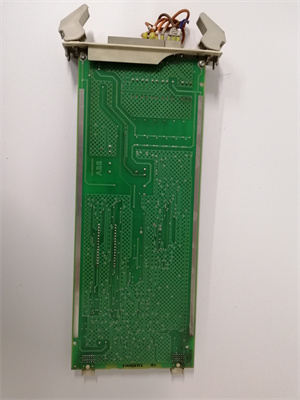

| Dimensions |

33.0 cm (W) x 5.1 cm (H) x 15.2 cm (D) |

| Weight |

0.3 kg |

| Certifications |

CE, RoHS compliant |

ABB TC520

-

High Reliability:

The TC520 incorporates redundant power inputs and a mean time between failures (MTBF) exceeding 100,000 hours, ensuring long-term stability in mission-critical applications. Its digital input filtering and error-state detection enhance system resilience.

-

Flexible Integration:

Supports seamless integration with ABB’s Advant controllers and third-party systems via standard protocols. The module’s compact design saves up to 20% space in control cabinets compared to bulkier alternatives.

-

Advanced Monitoring:

Collects status information from backplane buses and front connectors, providing real-time insights into system health. The “minute pulse” synchronization feature ensures accurate timekeeping across distributed systems.

-

Robust Design:

Built with a corrosion-resistant metal casing and rated for IP65 protection, the TC520 excels in high-vibration, dusty, or humid environments typical of steel mills, chemical plants, and offshore facilities.

- Manufacturing:

Ideal for assembly lines, robotic welding systems, and conveyor control, where real-time status monitoring reduces unplanned downtime.

- Energy:

Used in power plants and renewable energy systems to monitor substation automation and optimize grid stability.

- Process Control:

Deployed in chemical and pharmaceutical plants to ensure compliance with safety standards and regulatory requirements.

Case Study:

A major automotive manufacturer integrated the TC520 into its paint shop automation system to monitor robotic arms and conveyor belts. The module’s real-time data processing reduced cycle times by 15%, while its diagnostic tools minimized downtime by 20%, resulting in improved production throughput and consistent quality control.

Compared to similar industrial control modules, the TC520 offers:

- Superior Thermal Management: Operates efficiently in extreme temperatures without performance degradation.

- Broader Protocol Support: Native Modbus TCP/IP compatibility simplifies integration with modern systems.

- Compact Form Factor: Reduces cabinet space requirements by 20% compared to non-modular alternatives.

- Enhanced Security: Encrypted data transmission ensures cyber resilience in sensitive environments.

ABB TC520

When selecting the TC520 or similar components:

- Compatibility: Verify system requirements for Advant controller compatibility and communication protocols.

- Environmental Conditions: Ensure the operating temperature range matches your facility’s environment.

- Scalability: Assess future needs for I/O expansion and data processing capacity.

- Budget: Balance performance with cost, noting the TC520’s long-term value through reduced maintenance and downtime.

- Installation:

Follow ABB’s guidelines to avoid electrostatic discharge (ESD). Use shielded cables for communication connections to minimize EMI.

- Maintenance:

Regularly update firmware to access the latest features and security patches. Monitor voltage levels to prevent overloading.

- Safety:

Power down the system before installation or replacement. Store the module in a dry, dust-free environment within specified temperature ranges.

声明

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide ABB TC520 and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide