Description

The

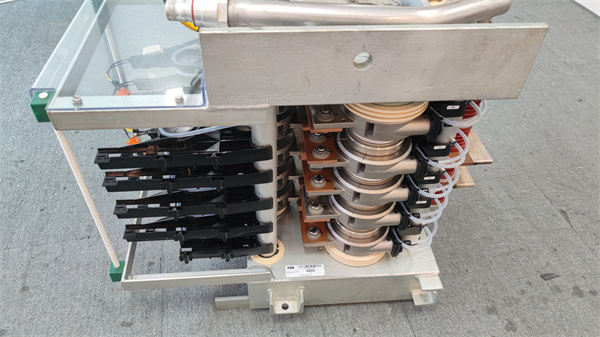

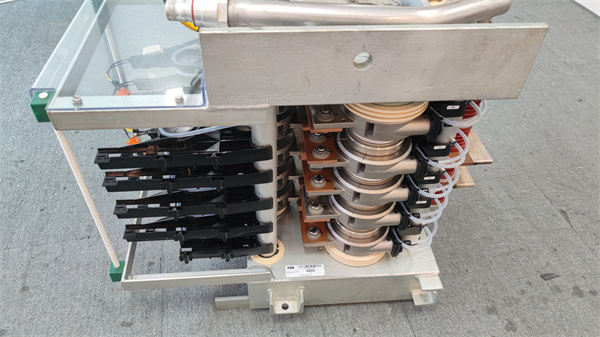

S – 113N 3BHB018008R0001 is a remarkable PLC spare part from a well – established brand in the industrial automation field. This model is engineered to meet the diverse needs of modern industrial control systems. Its core function lies in providing reliable and efficient control and monitoring capabilities. The

S – 113N 3BHB018008R0001 can process a large amount of input data from various sensors and execute corresponding control commands to ensure the smooth operation of industrial equipment.

In industrial applications, the S – 113N 3BHB018008R0001 is widely used in machinery control, process automation, and system monitoring. It offers significant advantages such as high – speed data processing, stable performance, and easy programmability. These features make it an ideal choice for industries that require precise and flexible control.

| Parameter |

Specification |

| Voltage |

24V DC |

| Current |

0.8A |

| Interface Types |

Ethernet, USB, RS – 485 |

| Compatibility |

Compatible with multiple industrial control software and hardware platforms |

| Operating Temperature |

-10°C to 50°C |

| Storage Temperature |

-20°C to 60°C |

| Memory Capacity |

8MB program memory, 4MB data memory |

| Processing Speed |

0.2 μs per instruction cycle |

The S – 113N 3BHB018008R0001 is known for its high – speed data processing. With a processing speed of 0.2 μs per instruction cycle, it can quickly respond to changes in the industrial environment, ensuring real – time control. It also has a high level of reliability, with a Mean Time Between Failures (MTBF) of over 60,000 hours. This means it can operate continuously for a long time without significant breakdowns.

The easy programmability of the S – 113N 3BHB018008R0001 allows users to customize control logic according to their specific requirements. It supports common programming languages, making it accessible to a wide range of industrial programmers.

This spare part is suitable for various industries, including automotive manufacturing, packaging, and food processing. In an automotive manufacturing plant, the S – 113N 3BHB018008R0001 is used to control the robotic painting process. It precisely controls the movement of the robots, the flow rate of the paint, and the spraying time. As a result, the quality of the painted surface has been significantly improved, and the production efficiency has increased by 20%.

Compared with other similar products in the market, the S – 113N 3BHB018008R0001 has several advantages. Some competing products may have slower processing speeds, which can lead to delays in control responses. The S – 113N 3BHB018008R0001 also offers better programmability and a wider range of communication interfaces, making it more flexible and easier to integrate into existing systems.

When selecting the S – 113N 3BHB018008R0001, users should first consider the compatibility with their existing industrial control systems. Ensure that the communication protocols and programming languages are supported. The installation environment is also crucial. If the environment is harsh, such as having high levels of dust or humidity, additional protective measures may be required. Budget is another important factor. Although the S – 113N 3BHB018008R0001 offers excellent performance, users should evaluate whether it fits their cost – effectiveness requirements.

During installation, follow the safety regulations strictly. Turn off the power supply before installation to avoid electrical shock. Regularly clean the device to prevent dust accumulation, which may affect its performance. Check the connection cables regularly to ensure they are firmly connected. Avoid exposing the device to extreme temperatures or strong electromagnetic fields.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner. We provide the

S – 113N 3BHB018008R0001 and other automation spare parts sales and technical support. Please visit our website

www.xydcontrol.com or contact us, and we will serve you whole – heartedly.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide