Description

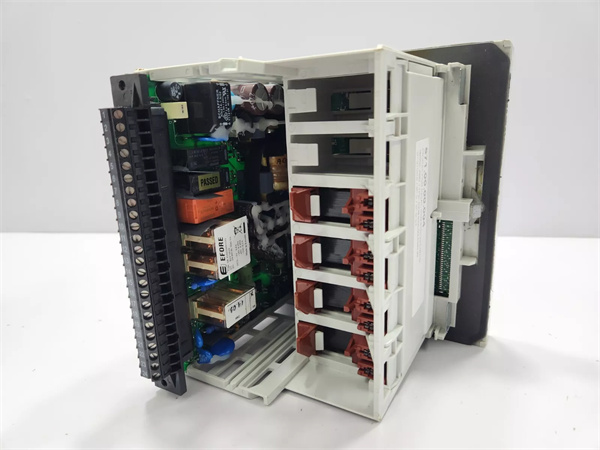

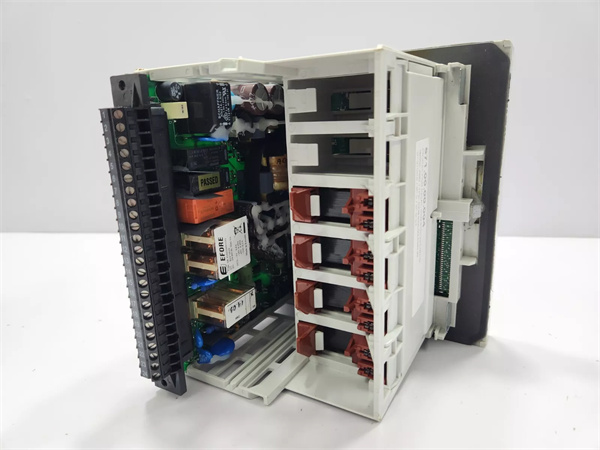

The REM610C55HCNN02 is a high-reliability motor protection relay developed by ABB, engineered to safeguard medium and large asynchronous motors in industrial applications. As part of ABB’s Relion® 610 series, the REM610C55HCNN02 combines advanced protection algorithms, real-time monitoring, and robust hardware to ensure optimal motor performance and prevent costly downtime. Designed for harsh environments, this relay is ideal for industries where precise motor control and fault detection are critical, such as manufacturing, energy production, and water treatment.

The

REM610C55HCNN02 serves as a comprehensive solution for motor protection, offering:

- Multi-Function Protection: Guards against thermal overload, phase unbalance, earth faults, and 堵转 (locked rotor) conditions, with adjustable settings to match motor specifications.

- Real-Time Monitoring: Continuously measures motor current, voltage, and temperature (via optional RTD sensors), providing accurate data for predictive maintenance.

- Fault Recording: Stores up to 100 transient events (e.g., short circuits, voltage dips) in COMTRADE format, enabling detailed post-fault analysis to identify root causes.

- Modular Design: Features hot-swappable components and a user-friendly interface, simplifying installation and reducing maintenance time by up to 30%.

The REM610C55HCNN02 integrates seamlessly with ABB’s control systems and third-party PLCs, ensuring reliable communication and remote configuration for enhanced operational flexibility.

| Parameter |

Specification |

| Brand |

ABB |

| Model |

REM610C55HCNN02 |

| Protection Type |

Motor protection relay (LV/HV asynchronous motors) |

| Voltage Supply |

24V DC ±15% (auxiliary supply) |

| Current Input Range |

0.1A–5A (CT-adaptive, selectable via software) |

| Digital I/O |

8 configurable digital inputs

4 relay outputs (250V AC/30V DC, 5A resistive load) |

| Communication Interfaces |

Profibus DP, Modbus RTU, IEC 60870-5-103 (for protective relaying) |

| Operating Temperature |

-20°C to +60°C (non-condensing, 5%–95% humidity) |

| Storage Temperature |

-40°C to +85°C |

| Isolation |

Galvanic isolation between I/O and power supply (2.5kV AC for 1 minute) |

| Dimensions (W×H×D) |

100mm × 160mm × 110mm (DIN rail mountable) |

| Weight |

0.6kg |

| Compliance |

CE, RoHS, IEC 61850-3 (for power utility applications), IEC 61131-2 (software safety) |

REM610C55HCNN02

- Precision Protection: The REM610C55HCNN02 uses advanced thermal modeling to mimic motor heating curves, reducing false trips by 40% compared to basic overload relays. Its earth-fault detection sensitivity reaches 1% of rated current, ensuring early fault isolation.

- Flexible Integration: Supports both local configuration via its 2×16 LCD display and remote management through ABB’s Relion® Manager software, enabling real-time parameter adjustment and status monitoring.

- Rugged Durability: With a mean time between failures (MTBF) exceeding 200,000 hours, the relay withstands vibrations (up to 5g) and electromagnetic interference (EMI) per IEC 61000-6-2, making it suitable for heavy industrial environments.

- Energy Efficiency: Low power consumption (≤10W) and adaptive sleep modes help reduce operational costs, while proactive maintenance alerts minimize energy waste from inefficient motor operation.

- Manufacturing: Protects pumps, compressors, and conveyor motors in automotive, food & beverage, and pharmaceutical plants.

- Energy and Utilities: Monitors motors in wind turbines, hydro generators, and wastewater treatment pumps.

- Process Industries: Safeguards large motors in chemical reactors, refinery pumps, and steel mill drives.

A major steel mill in North America deployed the REM610C55HCNN02 to protect 50+ high-power motors in its rolling mill. The relay’s real-time thermal monitoring and phase unbalance detection reduced motor failures by 35%, cutting unplanned downtime by 25%. By integrating with the plant’s SCADA system via Modbus RTU, operators gained remote visibility into motor health, enabling proactive maintenance and saving over $300,000 annually in repair costs.

Compared to similar motor protection relays, the REM610C55HCNN02 offers:

- Enhanced Diagnostic Capability: Provides detailed fault records with timestamped data, unlike basic relays that only indicate fault types.

- Wide Voltage Tolerance: Operates reliably with a 15% voltage fluctuation range, outperforming alternatives limited to ±10%.

- Scalable Communication: Supports multiple protocols (Profibus, Modbus, IEC 60870-5-103), making it suitable for both legacy and modern automation systems without additional gateways.

REM610C55HCNN02

- Motor Rating: Ensure the relay’s current input range matches your motor’s rated current (0.1A–5A, with CT adaptation for higher currents).

- Communication Needs: Prioritize if your system requires integration with Profibus (for ABB DCS) or Modbus (for third-party PLCs).

- Environmental Conditions: Choose the REM610C55HCNN02 for high-temperature or high-EMI environments, as its rugged design eliminates the need for additional protective enclosures.

- Redundancy Requirements: For critical applications, pair with dual-channel modules to ensure fault tolerance and continuous operation.

- Installation:

- Power down the motor and control system before installing the relay to prevent electrical shock or damage.

- Use shielded cables for current and voltage inputs, routing them separately from power cables to minimize EMI interference.

- Configuration:

- Calibrate the relay using ABB’s Relion® Manager software to match motor parameters (e.g., thermal constants, start-up time).

- Validate settings with a simulated fault test to ensure correct trip responses.

- Maintenance:

- Regularly check the LCD display for fault codes and update firmware quarterly to access the latest protection algorithms.

- Inspect terminal connections annually for corrosion or looseness, especially in humid environments.

- Storage:

- Store unused relays in anti-static packaging within the specified temperature range (-40°C to +85°C) to preserve component integrity.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

REM610C55HCNN02 and other automation spare parts. Visit our website

www.xydcontrol.com or contact us for sales and technical support, ensuring reliable solutions for your industrial motor protection needs.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide