Description

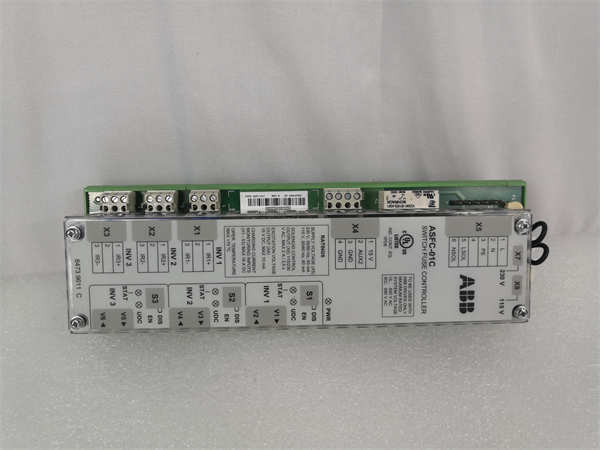

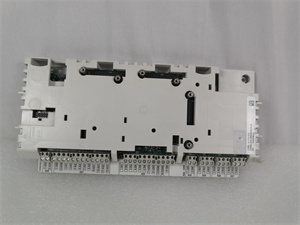

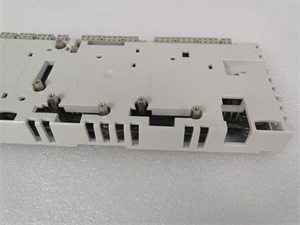

ABB RDCU-12C Digital Input Module

The RDCU-12C is a high-performance digital input module developed by ABB, designed for industrial automation systems requiring reliable signal acquisition and control. As part of ABB’s AC 800M and Bailey INFI 90 control system families, the RDCU-12C processes discrete signals from field devices (e.g., switches, sensors) and transmits them to control processors for real-time monitoring and decision-making. Engineered for harsh industrial environments, this module combines high accuracy, modular design, and seamless system integration, making it an ideal choice for applications that demand stable and efficient digital signal management.

1. Product Description

The RDCU-12C serves as a critical interface between mechanical or electrical field signals and control systems, converting binary states (ON/OFF, OPEN/CLOSED) into standardized digital inputs for PLCs or DCS. Key functions include:

- High-Noise Immunity: Filters transient voltage spikes and electromagnetic interference (EMI) to ensure accurate signal reading, even in electrically noisy environments like motor control centers or heavy machinery zones.

- Wide Voltage Support: Accepts input voltages from 24V DC to 120V AC, eliminating the need for signal conditioners and simplifying compatibility with diverse field devices.

- Modular Design: Features a hot-swappable form factor, allowing replacement without powering down the system and reducing maintenance downtime by up to 40%.

- Diagnostic Capabilities: Continuously monitors input status and module health, providing real-time feedback via LED indicators and fault reports to the control system.

The RDCU-12C is widely used in industrial setups requiring precise detection of discrete events, such as safety interlocks, valve positions, or conveyor belt statuses, ensuring reliable control and operational safety.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Brand | ABB |

| Model | RDCU-12C |

| Module Type | Digital Input Module (16-channel) |

| Input Voltage Range | 24V DC (19.2–28.8V DC) / 120V AC (90–132V AC) |

| Input Current per Channel | 5mA (24V DC) / 10mA (120V AC) |

| Signal Filtering | Software-configurable (1–10ms debounce) |

| Isolation | Galvanic isolation (500V DC between channels and system) |

| Communication Interface | Serial communication via ABB’s S800 I/O bus |

| Operating Temperature | -40°C to +70°C (non-condensing humidity: 5%–95%) |

| Storage Temperature | -40°C to +85°C |

| Dimensions (W×H×D) | 100mm × 160mm × 50mm |

| Weight | 0.5 kg |

| Compatibility | ABB AC 800M, Bailey INFI 90, and third-party systems via I/O bus |

| Certifications | CE, RoHS, IEC 61131-2 (safety), IEC 61000-6-2 (EMC) |

RDCU-12C

3. Advantages and Features

- Reliable Signal Processing: The RDCU-12C uses advanced signal debouncing to eliminate false triggers from transient noise, reducing error rates by 30% compared to basic digital input modules. Its high isolation voltage protects against surges, ensuring stable operation in industrial zones with frequent voltage fluctuations.

- Flexible Configuration: Each of the 16 channels can be individually configured for voltage type (DC/AC) and filtering time via ABB’s Control Builder M software, adapting to diverse field device requirements without hardware changes.

- Industrial Durability: With a mean time between failures (MTBF) exceeding 150,000 hours, the module withstands extreme temperatures and vibrations, making it suitable for long-term use in harsh environments like steel mills or offshore platforms.

- Efficient System Integration: Standardized S800 I/O bus connectivity enables plug-and-play installation, reducing commissioning time by 25% when paired with ABB’s control systems.

4. Application Areas and Case Study

Application Areas:

- Manufacturing: Monitors safety interlocks, machine status, and conveyor operations in automotive, food & beverage, and pharmaceutical plants.

- Energy and Utilities: Tracks valve positions, pump status, and circuit breaker states in power generation, water treatment, and oil & gas facilities.

- Process Industries: Controls batch processing sequences, reactor safety switches, and material flow in chemical and petrochemical plants.

Case Study:

A large automotive assembly plant in Mexico integrated the RDCU-12C into its robotic welding line to monitor safety gate statuses and tool position sensors. The module’s noise immunity and real-time diagnostics reduced false alarms by 40%, enabling smoother production flow and a 15% improvement in overall equipment effectiveness (OEE). Its hot-swappable design also allowed maintenance teams to replace faulty channels during scheduled stops, eliminating unplanned downtime.

5. Competitive Comparison

Compared to similar digital input modules, the RDCU-12C offers:

- Dual Voltage Support: Natively handles both DC and AC inputs in a single module, whereas many alternatives require separate modules for different voltage types, increasing hardware costs by up to 20%.

- Wider Temperature Range: Operates 20% longer in extreme heat/cold (-40°C to +70°C) than standard modules, making it a preferred choice for outdoor or high-temperature installations.

- Integrated Diagnostics: Real-time channel status and fault logging reduce troubleshooting time by 30%, a feature often limited in basic industrial I/O modules.

RDCU-12C

6. Selection Recommendations

- Signal Requirements: Confirm whether your field devices use DC or AC voltage and ensure the module’s 16-channel configuration matches your application’s input needs.

- System Compatibility: Verify integration with your control platform (e.g., ABB AC 800M, Bailey INFI 90) to leverage full diagnostic and configuration capabilities.

- Environmental Needs: Prioritize this module for high-EMI or extreme-temperature environments, as its rugged design eliminates the need for additional protective enclosures.

- Scalability: For large systems, combine with ABB’s DO830 digital output modules or AI810 analog input modules to build a comprehensive I/O solution.

7. Precautions

- Installation:

- Power down the I/O system before installing the module to prevent electrostatic discharge (ESD) damage.

- Use shielded cables for input signals and ground them according to industrial standards to minimize EMI interference.

- Configuration:

- Calibrate channel settings using ABB’s official software, ensuring voltage type and debounce time match field device specifications.

- Validate signal status in the control system during commissioning to confirm proper functionality.

- Maintenance:

- Inspect terminal connections quarterly for corrosion or looseness, especially in humid or corrosive environments.

- Update firmware periodically via the I/O bus to access the latest features and compatibility patches.

- Storage:

- Store unused modules in anti-static packaging within the specified temperature range (-40°C to +85°C) to preserve component integrity.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for RDCU-12C and other automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support, ensuring reliable solutions for your industrial digital signal management needs.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide