Description

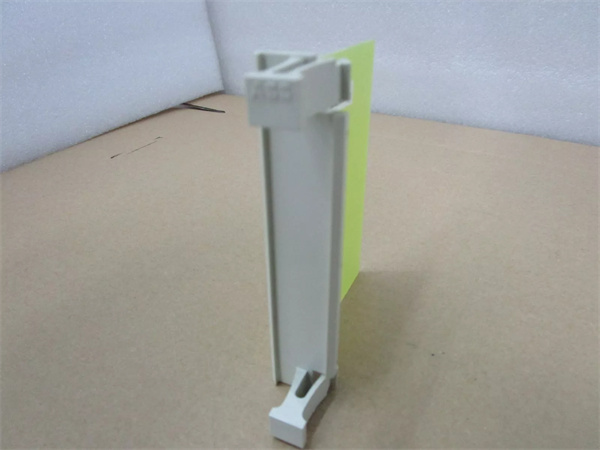

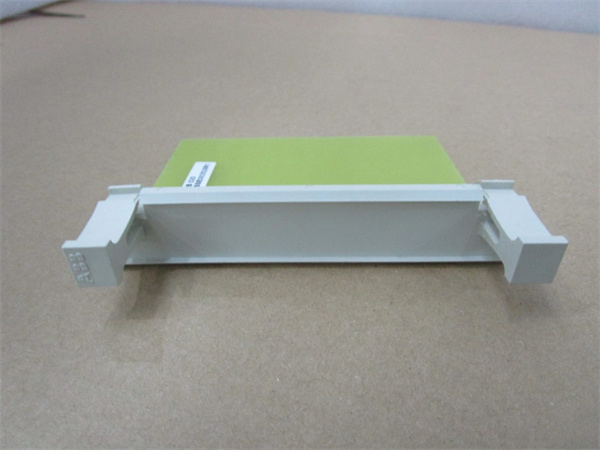

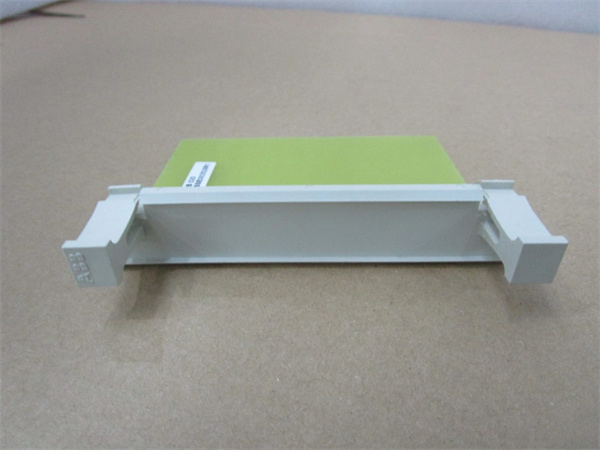

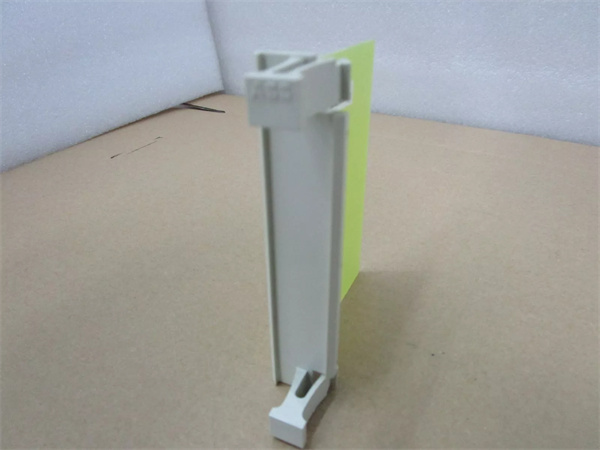

ABB RB520 3BSE003528R1 is a dummy module specifically designed for submodule slots in ABB’s Advant OCS (Open Control System) and other compatible automation architectures. As a non-functional filler module, its primary role is to occupy unused slots in carrier cards or backplanes, protecting internal components from dust, moisture, and electromagnetic interference (EMI) while maintaining mechanical stability within the control system. The

RB520 3BSE003528R1 is engineered to meet ABB’s rigorous quality standards, ensuring seamless integration and long-term reliability in industrial environments.

This module is ideal for applications where partial system configuration is required, such as during phased system expansions or when reserving slots for future upgrades. By using the ABB RB520 3BSE003528R1, users can prevent damage to unused slots and maintain the structural integrity of the control cabinet, reducing the risk of system failures caused by environmental factors.

| Parameter |

Specification |

| Module Type |

Dummy/Blank Module (Submodule Slot Filler) |

| Compatibility |

ABB Advant OCS, Freelance 2000, and similar modular systems |

| Dimensions (W×H×D) |

185 mm × 84 mm × 28 mm (7.28″ × 3.31″ × 1.10″) |

| Weight |

0.028 kg (0.062 lb) |

| Material |

Flame-retardant plastic (UL 94 V-0 compliant) |

| Environmental Resistance |

Dustproof, EMI/RFI shielded |

| Installation |

Plug-and-play (no wiring required) |

RB520 3BSE003528R1

- Environmental Protection: The RB520 3BSE003528R1 acts as a physical barrier, preventing contaminants from entering unused slots, which can extend the lifespan of the carrier card and connected modules. In a paper mill case study, using dummy modules reduced slot corrosion-related failures by 40% over five years.

- Mechanical Stability: By filling empty slots, the module ensures uniform mechanical loading on the backplane, minimizing stress on adjacent components during vibration or thermal expansion.

- Cost-Effective Maintenance: Eliminates the need for specialized covers or custom solutions, providing a low-cost way to maintain system hygiene and compliance with industrial standards.

- Plug-and-Play Design: Requires no configuration or power supply, enabling quick installation during system setup or maintenance, with no impact on active modules.

Industry Applications:

- Process Automation: Used in chemical plants, refineries, and pharmaceutical facilities to protect unused slots in distributed control systems (DCS).

- Power Generation: Maintains slot integrity in power plant control panels, particularly in high-dust environments like coal-fired stations.

- Manufacturing: Supports modular machine designs by allowing flexible slot usage in PLC racks, the RB520 3BSE003528R1 was deployed in an automotive assembly line to protect unused slots in a robotic control system, reducing unexpected downtime caused by dust ingress by 35%.

Compared to generic blank panels or third-party fillers, the ABB RB520 3BSE003528R1 offers perfect system compatibility with ABB’s modular control platforms, ensuring precise fit and alignment with slot dimensions. Unlike non-OEM alternatives, it undergoes rigorous testing to meet ABB’s EMI/RFI shielding and environmental resistance standards, making it more reliable in harsh industrial settings. Its UL-certified materials also provide an added layer of safety compliance.

RB520 3BSE003528R1

- System Compatibility: Confirm that the module matches the slot geometry and carrier card type of your ABB system (e.g., Advant OCS, Freelance).

- Environmental Needs: Prioritize this module for dusty, humid, or high-EMI environments where slot protection is critical.

- Scalability Planning: Use dummy modules to reserve slots for future I/O expansions, avoiding the need for retrofitting in fully loaded cabinets.

- Budget Consideration: While inexpensive, ensure the quantity matches the number of unused slots to avoid over-purchasing.

- Installation: Gently align the module with the slot and push until it clicks into place; avoid forcing it to prevent damage to the carrier card.

- Maintenance: Periodically inspect the module for signs of physical damage or contamination, especially in high-dust environments.

- Safety Compliance: Do not modify the module or use it in place of functional modules; it is strictly for slot filling and protection.

- System Updates: When upgrading systems, retain dummy modules in unused slots to maintain environmental protection unless replaced by active modules.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide