Description

The

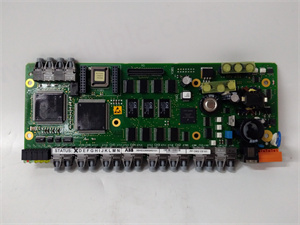

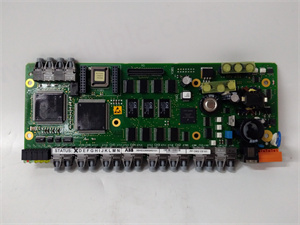

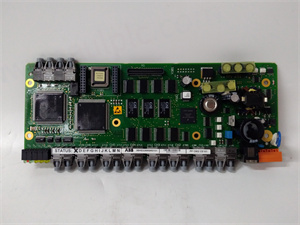

ABB PPC902CE101 (3BHE028959R0101) is a high-performance controller module designed for industrial automation and motor control applications. As part of ABB’s advanced PLC and drive systems, the

PPC902CE101 delivers precise control, robust reliability, and seamless integration with industrial networks. This module is engineered for high-voltage motor control, enabling adjustable speed and torque regulation while supporting complex automation workflows. Key features include built-in motor protection (overload, overheat), multi-protocol communication (Profibus DP, Modbus TCP/IP), and compatibility with standard IEC 61131-3 programming languages (LD, ST, FBD). The

PPC902CE101 is ideal for industries requiring scalable, high-efficiency control solutions, such as manufacturing, energy, and process automation.

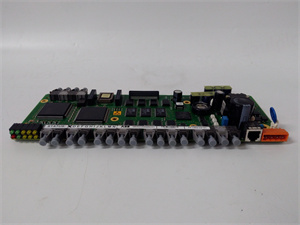

| Parameter |

Specification |

| Voltage |

24V DC (operational), 100–240V AC (power supply) |

| Current |

≤500mA (operational) |

| Communication Interfaces |

RJ45 (Ethernet), Profibus DP, Modbus TCP/IP |

| Memory |

Built-in RAM and flash memory for program storage |

| Protection Class |

IP20 (enclosure-ready) |

| Compatibility |

ABB S800 I/O systems, CEX-Bus expansion |

| Dimensions |

Compact form factor for modular installations |

PPC902CE101

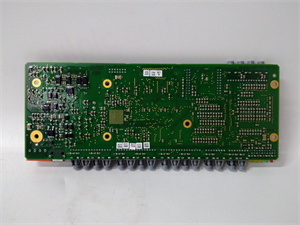

- High Reliability: Industrial-grade design with EMC certification and redundant Ethernet ports for continuous operation.

- Flexible Integration: Supports modular expansion via CEX-Bus and seamless integration with ABB’s PLC and drive ecosystems.

- Motor Protection: Integrated overload, overheat, and short-circuit protection enhance system longevity.

- Energy Efficiency: Precise speed control reduces energy consumption in motor-driven applications.

- Programming Flexibility: Standard IEC 61131-3 languages enable custom logic development for diverse use cases.

Industries: Manufacturing, energy, chemical processing, water treatment, and automotive.

Applications: High-voltage motor control, process automation, conveyor systems, and machine tools.

Case Study: A chemical plant upgraded its pump system with the PPC902CE101, achieving 15% energy savings and 20% reduction in downtime through predictive maintenance features.

Compared to similar modules, the PPC902CE101 stands out with:

- Dual Redundancy: Redundant Ethernet ports and CEX-Bus support for mission-critical systems.

- Integrated Safety: Built-in motor protection eliminates the need for external safety modules.

- Scalability: Modular design allows step-by-step system expansion without hardware replacement.

PPC902CE101

- Compatibility: Ensure alignment with existing ABB systems (e.g., S800 I/O, PM891 processors).

- Environment: Consider IP rating (IP20) and temperature range (0–50°C) for installation conditions.

- Budget: Balance features (e.g., redundancy, communication protocols) with project requirements.

- Long-Term Support: ABB’s lifecycle management ensures ongoing firmware updates and 备件 availability.

- Installation: Follow ABB’s wiring guidelines for proper voltage and grounding.

- Maintenance: Regularly inspect connections and monitor temperature for optimal performance.

- Software: Use ABB’s official tools (e.g., AC500 Programming Tool) for configuration and updates.

- Safety: Disconnect power before servicing to avoid electrical hazards.

声明: Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

PPC902CE101 and other automation spare parts. We provide sales, technical support, and comprehensive solutions. Visit our website

www.xydcontrol.com or contact us for customized assistance.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide