Description

1. Product Description

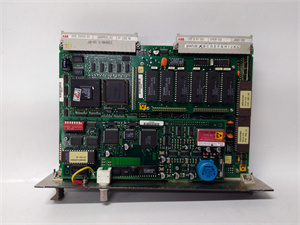

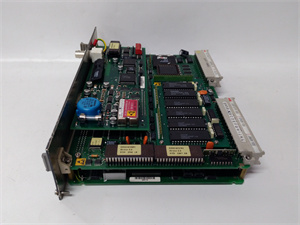

PPC322BE is a high-performance central processing unit (CPU) module produced by ABB. It plays a crucial role in industrial automation control systems. The PPC322BE is designed to handle complex control tasks with its powerful processing capabilities. Its core function is to receive input signals from various sensors and devices, process these signals through complex algorithms, and then send out control commands to actuators to ensure the smooth operation of the industrial system.

This module is widely used in different industrial scenarios. For example, in manufacturing plants, it can be used to control the production line, ensuring the precision and efficiency of production processes. In energy facilities, the PPC322BE helps manage power generation, distribution, and consumption, optimizing energy utilization. One of the significant advantages of the PPC322BE is its high reliability. It is built with high-quality components and advanced manufacturing processes, enabling it to operate stably in harsh industrial environments. Additionally, its flexibility in communication allows it to easily integrate with other devices and systems, making it a preferred choice for many industrial automation projects.

2. Product Parameters

- Processor: PPC603E processor with a main frequency of 166 MHz

- Memory: 32 MB RAM and 8 MB Flash

- Input/Output Ports:

- 12 digital inputs

- 8 digital outputs

- 4 analog inputs

- 4 analog outputs

- Communication Interfaces:

- 2 RS232 serial ports

- 1 RS485 serial port

- 1 Ethernet interface

- Operating Voltage: 24 VDC

- Power Consumption: Approximately 10 W

- Operating Temperature Range: -20°C to 60°C

- Compatibility: Compatible with various ABB automation systems and some third-party devices with standard communication protocols

3. Advantages and Characteristics

- High Reliability: The PPC322BE has been tested and proven in numerous industrial applications. In a large chemical plant, it has been running continuously for over 5 years without major failures, ensuring the stable operation of the production process. Its MTBF (Mean Time Between Failures) is estimated to be over 100,000 hours, which is much higher than many similar products in the market.

- Easy Integration: With its multiple communication interfaces, the PPC322BE can be easily integrated into existing industrial automation systems. In a recent project in a food processing factory, it only took technicians about 3 days to integrate the PPC322BE into the existing control system, minimizing the impact on production.

- Powerful Processing Capability: The 166 MHz PPC603E processor enables the PPC322BE to handle complex control algorithms and process a large amount of data in real-time. In a high-speed manufacturing line, it can quickly respond to sensor signals and adjust the operation of the equipment, improving production efficiency by 20%.

4. Application Areas and Application Cases

- Application Areas: The PPC322BE is suitable for a wide range of industries, including manufacturing, energy, water treatment, and transportation. In manufacturing, it can be used for robotic control, assembly line automation, and quality control. In the energy industry, it is applied in power plants, substations, and renewable energy systems. In water treatment plants, it helps monitor and control the water treatment process. In transportation, it can be used in traffic control systems and railway signaling systems.

- Application Case: In a large automotive manufacturing plant, the PPC322BE was used to control the robotic arms on the production line. The module received signals from various sensors, such as position sensors and force sensors, and processed these signals to precisely control the movement of the robotic arms. As a result, the production efficiency increased by 30%, and the defect rate of the products decreased by 50%. The high reliability and powerful processing capability of the PPC322BE ensured the stable operation of the production line.

5. Comparison with Competitors

Compared with some similar CPU modules in the market, the PPC322BE has several advantages. In terms of reliability, its long MTBF and stable performance in harsh environments make it more trustworthy. In terms of communication flexibility, its multiple communication interfaces support a wider range of communication protocols, enabling it to integrate with more diverse devices and systems. Moreover, the PPC322BE’s powerful processing capability allows it to handle more complex control tasks, providing better performance in high-demand industrial applications.

6. Selection Suggestions

- Compatibility: When selecting the PPC322BE, make sure it is compatible with your existing industrial automation system. Check the communication protocols and interface types to ensure seamless integration. If you are using other ABB products, the PPC322BE is likely to have better compatibility.

- Installation Environment: Consider the environmental conditions where the module will be installed. If the installation location has high temperatures, humidity, or strong electromagnetic interference, ensure that the PPC322BE can operate stably in such an environment. Its operating temperature range of -20°C to 60°C makes it suitable for most industrial environments, but additional protection may be needed in extreme cases.

- Budget: Although the PPC322BE offers excellent performance and reliability, you also need to consider your budget. Compare the prices of different suppliers and evaluate the cost-effectiveness. Sometimes, investing a little more in a high-quality module like the PPC322BE can save you more in the long run due to reduced maintenance and downtime costs.

7. Precautions

- Safety Specifications: When installing the PPC322BE, make sure to cut off the power supply to avoid electric shock. Follow the installation instructions carefully and use appropriate tools. Wear anti-static wristbands to prevent damage to the module caused by static electricity.

- Maintenance Suggestions: Regularly check the operation status of the PPC322BE. Clean the module’s surface and ventilation holes to prevent dust accumulation. Check the connection of the communication cables and power cables to ensure they are secure. If any abnormal phenomena are found, such as overheating or abnormal noise, stop the operation immediately and contact professional technicians for inspection and maintenance.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide the sales and technical support of PPC322BE and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide