Description

The

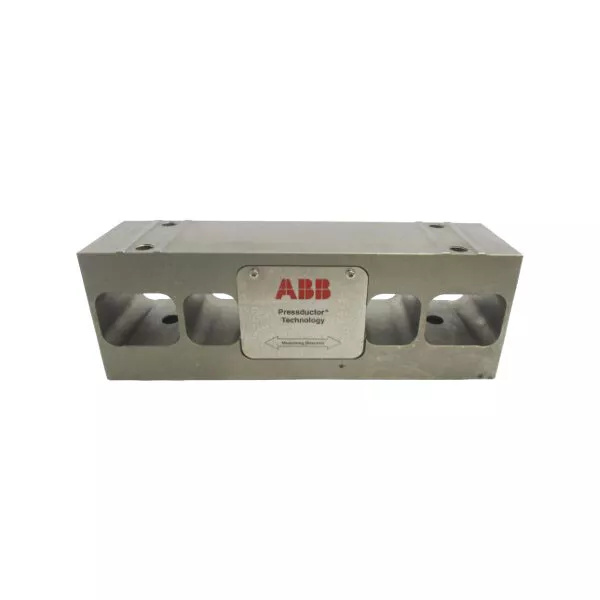

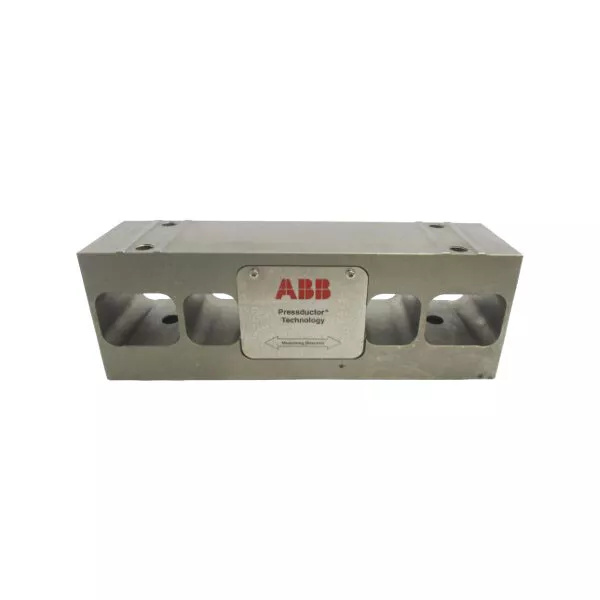

ABB PFTL101B 20KN (part number: 3BSE004203R1) is a

mechanical tension load cell designed for precise measurement of tensile forces in industrial applications. Belonging to ABB’s

PFTL series, this load cell is engineered for durability, accuracy, and reliability in harsh environments, making it suitable for heavy-duty industries such as manufacturing, material handling, and process control.

-

Design and Construction

- Load Capacity: Rated for 20 kN (approximately 2,000 kg or 4,400 lbs), with a compact and robust design for direct tension measurement.

- Material: Constructed from high-strength stainless steel, offering corrosion resistance and long-term stability in challenging conditions (e.g., moisture, dust, or chemical exposure).

- Mechanical Interface: Features threaded ends (e.g., male/female threads) for easy integration into lifting systems, rigging, or tensioning mechanisms.

-

Technical Specifications

| Parameter |

Description |

| Model |

PFTL101B |

| Part Number |

3BSE004203R1 |

| Product Type |

Tension Load Cell (Axial Load Cell) |

| Nominal Capacity |

20 kN |

| Accuracy Class |

Typically meets 0.1% to 0.3% of rated load (depending on calibration). |

| Output Signal |

Analog (e.g., mV/V) or digital (via optional transmitters), compatible with ABB’s measurement systems. |

| Environmental Rating |

– Operating temperature: -30°C to +80°C,

– IP67/IP68 protection against dust and water ingress. |

| Certifications |

Compliance with international standards (e.g., OIML R60 for weighing applications, if applicable). |

-

Functional Features

- High Rigidity: Minimizes deformation under load for accurate and repeatable measurements.

- Overload Protection: Designed to withstand temporary overloads (e.g., up to 150% of rated capacity) without permanent damage.

- Hermetic Sealing: Prevents internal component degradation from environmental contaminants, ensuring long service life.

-

-

PFTL101B 20KN 3BSE004203R1

-

Lifting and Hoisting Systems

- Monitoring cable tension in cranes, elevators, or overhead lifting equipment to prevent overloading and ensure safety.

- Quality control in manufacturing lines for precise load measurement during assembly or testing.

-

Material Handling and Conveyors

- Tension control in belt conveyors, wire rope systems, or textile production lines to maintain optimal process efficiency.

- Preventing belt slippage or breakage by continuously measuring and adjusting tension.

-

Industrial Machinery and Equipment

- Force measurement in presses, testing machines, or robotic systems for process optimization and fault detection.

- Monitoring tension in wire/rope production, cable laying, or packaging equipment.

-

Renewable Energy and Infrastructure

- Tension measurement in wind turbine mooring systems, solar tracker structures, or bridge stay cables for structural health monitoring.

PFTL101B 20KN 3BSE004203R1

-

Mechanical Installation

- Mounted in-line with the load path (e.g., between a hook and cable, or within a tensioning mechanism).

- Ensure proper alignment to avoid lateral or bending forces, which can introduce measurement errors.

-

Electrical Connection

- Connects to a signal conditioner or data acquisition system (e.g., ABB’s PLCs or drives) via shielded cables to minimize electromagnetic interference (EMI).

- Optional transmitters can convert the analog output to digital signals (e.g., 4–20 mA, Modbus RTU) for integration with SCADA or IoT platforms.

-

Calibration and Maintenance

- Factory-calibrated for immediate use, with traceable calibration certificates available upon request.

- Periodic recalibration recommended for critical applications to maintain accuracy over time.

- ABB PFTL Series Load Cells

- Other models with different load capacities (e.g., 5 kN, 50 kN, 100 kN) for scalable force measurement needs.

- ABB Measurement and Automation Solutions

- ACS880 drives, PLCs (e.g., AC500), or instrumentation (e.g., transmitters) for full system integration.

- ABB Safety Systems

- Integration with Safety PLCs (e.g., SafeMove) for real-time load monitoring and overload protection in safety-critical applications.

The PFTL101B 20KN 3BSE004203R1 is available through ABB’s authorized distributors or directly from ABB’s industrial automation division. Technical documentation, including datasheets, installation guides, and calibration reports, can be accessed via ABB’s official website. For custom configurations or application-specific support, contact ABB’s measurement and analytics team.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide