Description

1.Product description

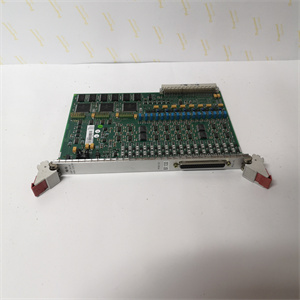

ABB’s PFSK151 is a high-performance communication and control module.PFSK151 is mainly used in industrial automation systems,performing key tasks such as data communication,signal processing and equipment control.It can support a variety of communication protocols to achieve data transmission and reception between different devices and systems.With advanced technology and design,PFSK151 can work with PLC,DCS and other equipment,widely used in manufacturing,power,chemical,water treatment and many other fields,to provide strong support for the efficient operation of industrial automation systems.

2.Product parameters

Parameter details

Operating voltage+5V DC,±10%,maximum 200mA

Power Options Two 24VDC power options

I/O 8 inputs and 6 outputs,scalable to 142 I/O points

Storage capacity 8K step flash EPROM program memory,8K word data storage

Communication protocols support Profibus,DeviceNet,Modbus,TCP/IP,EtherNet/IP,etc

Communication interface Ethernet,RS232/485,etc

Operating temperature 0°C to 60°C

Humidity Max.Relative Humidity 95%(non-condensing)

Protection class IP20

3.Advantages and characteristics

Strong communication capability:supports a variety of communication protocols and interfaces,and can communicate seamlessly with different manufacturers and different types of equipment and systems,such as in a large industrial automation project containing a variety of brands of equipment,PFSK151 can easily achieve data interaction between devices,avoiding system integration problems caused by incompatibility of communication protocols.

Flexible I/O configuration:The initial 8 inputs and 6 outputs can be extended to 142 I/O points,which can meet a variety of industrial control needs from simple to complex,such as in the automotive production line,according to the number of sensors and actuators at different stations can be flexibly expanded I/O points to achieve accurate production control.

Storage stability:8K step flash EPROM program memory and 8K word data storage,to ensure the stable storage of a large number of program data and configuration information,to ensure that the system in the case of power failure and other data is not lost,to maintain stable operation.

Strong anti-interference ability:in line with EMC standards,it can also work stably in harsh industrial environments such as strong electromagnetic interference,such as in complex electromagnetic environments such as steel mills,and can carry out reliable data processing and communication.

4.Application fields and application cases

Applications:In the manufacturing industry,for the automatic control and monitoring of production equipment;In the power industry,it can realize the data communication and control of the grid distribution automation system;In the field of chemical industry,it can monitor and control various parameters in the chemical production process.In the water treatment industry,it can be used for equipment control and data acquisition of water treatment systems.

Application case:ABB PFSK151 module is used in the production control system of a large chemical enterprise.It is responsible for connecting various sensors and controllers,transmitting the temperature,pressure,flow and other data collected by the sensors to the central control system through the supported communication protocol,and transmitting the control instructions of the central control system to the actuator to achieve accurate control of the chemical production process.After using PFSK151,the stability of the production process is increased by 20%,and the production accidents caused by communication failures are reduced by 30%,effectively improving the production efficiency and product quality.

5.Comparison of competitive products

Compared with similar products on the market,PFSK151 has obvious advantages in the richness of communication protocol support,and can support more types of fieldbus and Ethernet protocols,and has stronger compatibility.It is also excellent in terms of I/O scalability,with more expandable I/O points,which can better meet the needs of complex industrial projects.Moreover,its storage capacity performs well in data storage stability and storage capacity,which can provide reliable data guarantee for system operation.At the same time,the anti-interference ability of PFSK151 makes it more adaptable in harsh industrial environments and can work more stably than some competing products.

6.Selection suggestions

Compatibility considerations:In the selection,it is necessary to ensure that PFSK151 is compatible with existing industrial automation systems and equipment in terms of communication protocols and interface types.Carefully evaluate the communication standards used by other devices in the system to ensure that PFSK151 can communicate with them and avoid communication barriers.

I/O demand assessment:Reasonably plan the number of I/O points according to the number of input signals to be monitored and the number of output devices to be controlled in the actual project.In consideration of possible future system expansion needs,a certain amount of I/O expansion space is reserved to ensure that the I/O configuration of the PFSK151 can meet long-term production control requirements.

Environmental adaptability:Consider the working environment conditions of PFSK151,such as temperature,humidity,and electromagnetic interference.If there are harsh environmental factors such as high temperature,high humidity or strong electromagnetic interference on the project site,ensure that the protection level and anti-interference ability of the module can be adapted to ensure its stable operation.

Budget considerations:take into account the purchase cost and maintenance cost of PFSK151 as well as its performance and functionality.On the premise of meeting the technical requirements of the project,compare the prices and services of different suppliers,choose cost-effective products,and avoid unnecessary costs.

7.Precautions

Installation Procedure:When installing the PFSK151 module,strictly follow the product installation manual.Ensure that the installation position is well ventilated to avoid overheating due to poor heat dissipation.Correctly connect the power supply and communication lines,pay attention to the polarity and interface matching,to prevent damage to the module due to wiring errors.

Operation and maintenance:During the operation of the module,check its working status regularly and observe the indicator display.If it is found that the abnormal indicator lights up or the module appears abnormal heat,noise and other phenomena,stop the machine in time to check and eliminate the fault.Clean the module regularly to remove dust and debris on the surface to ensure normal heat dissipation and performance.

Software management:Back up the original configuration data before configuring or updating the PFSK151 module to prevent data loss.Ensure that the software version is compatible with the module,and configure and update the software according to the correct steps to prevent the module from working properly due to software problems.

Shanxi Xinyeda International Trading Co.,Ltd.is your trusted partner,we provide PFSK151 and other automation spare parts sales and technical support.You can contact us through the relevant channels,we will be happy to serve you.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide