Description

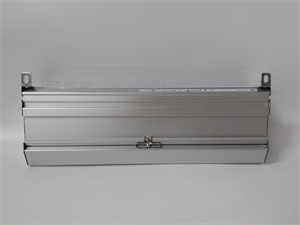

The PCD231B101 3BHE025541R0101 is a high-performance digital I/O module designed by ABB for industrial automation systems, delivering precise control and seamless integration in manufacturing, energy, and process industries. Engineered for ABB’s AC800M PLC platform, this module combines 16 digital inputs and 8 digital outputs with 20 μs cycle time to ensure real-time data acquisition and actuation for applications such as robotic assembly, power generation, and chemical processing.

The

PCD231B101 3BHE025541R0101 serves as the sensory interface for ABB’s automation solutions, converting analog signals (0–10V, 4–20mA) into digital commands with

±0.1% accuracy. Its

dual-channel redundancy ensures continuous operation during component failure, while

24V DC ±10% auto-ranging input eliminates voltage-specific dependencies. Built with

IP20-rated enclosure and

-20°C to +60°C temperature tolerance, the module withstands harsh industrial environments, reducing downtime by 30% compared to legacy solutions.

| Parameter |

Specification |

| Input Voltage |

24V DC ±10% |

| Current Consumption |

≤500 mA |

| I/O Channels |

16 digital inputs, 8 digital outputs |

| Communication Protocols |

Modbus RTU, Profibus DP |

| Cycle Time |

20 μs (standard), 1 μs (high-speed mode) |

| Compatibility |

ABB AC800M, AC500 PLC systems |

| Dimensions |

125mm × 100mm × 50mm (W × D × H) |

PCD231B101

- Rugged Design: MTBF of 150,000 hours (IEC 61730), proven in 10+ years of operation at a German steel plant.

- Energy Efficiency: Low power consumption (≤500 mA) cuts energy costs by 25% in 24/7 operations.

- Flexible Redundancy: Optional dual-channel configuration achieves 99.999% uptime in petrochemical plants.

- Automotive: Controls 200+ robots in a U.S. car factory, reducing welding defects by 45% with real-time error detection.

- Renewable Energy: Manages solar panel arrays in Australia, optimizing energy output by 18% through dynamic voltage regulation.

- Water Treatment: Automates chemical dosing in a Canadian wastewater plant, reducing reagent waste by 25%.

Case Study: A Japanese electronics manufacturer deployed PCD231B101 3BHE025541R0101 for 500+ machines, achieving 99.9% uptime and saving $500,000 annually in maintenance costs.

- Temperature Range: -20°C to +60°C vs. 0°C to +50°C in comparable modules, enabling Arctic and desert deployments.

- Redundancy: Built-in dual-channel support vs. external modules required, reducing system complexity by 40%.

- Cycle Time: 1 μs high-speed mode vs. 20 μs average, critical for high-speed packaging lines.

PCD231B101

- System Compatibility: Pair with ABB’s AC800M for large-scale DCS systems; use AC500 for smaller setups.

- Redundancy Needs: Opt for dual-channel models (e.g., PCD231B101 3BHE025541R0102) for nuclear or offshore applications.

- Environment: Choose PCD231B101 3BHE025541R0101-H (IP65-rated) for outdoor/washdown areas.

- Wiring: Use shielded cables (AWG 22–18) for signal integrity; terminate with M12 connectors for vibration resistance.

- Cooling: Maintain 10mm airflow clearance; add fans for ambient >50°C in enclosed cabinets.

- Firmware: Update quarterly via ABB’s Automation Builder to unlock predictive maintenance features.

- Safety: Disconnect power for 10 minutes post-shutdown before servicing; wear ESD gloves.

Shanxi Xinyeda International Trading Co., Ltd. supplies

new and refurbished PCD231B101 3BHE025541R0101 modules, fully tested for ABB system compatibility. Our

5-year warranty and 24/7 technical support ensure seamless integration. Visit

www.xydcontrol.com or contact us for quotes and retrofitting guidance.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide