Description

The

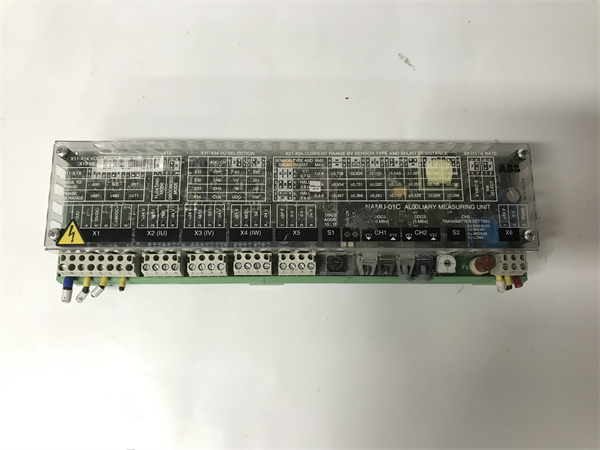

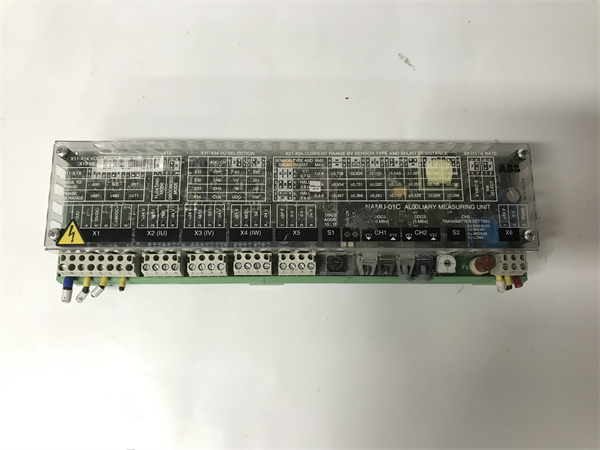

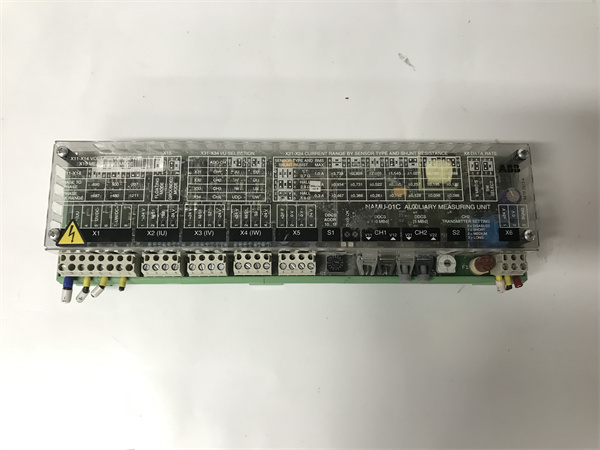

ABB NAMU-01C 64702475D is a high-performance

network adapter module designed for ABB’s industrial robotics and automation systems, serving as a critical interface for seamless communication between robotic controllers, PLCs, and higher-level manufacturing networks. As part of ABB’s

IRC5 Robot Controller ecosystem, the

NAMU-01C 64702475D enables real-time data exchange and remote monitoring in smart factories, where precision synchronization and reliable connectivity are essential for optimizing productivity. This module supports multiple industrial communication protocols, including Ethernet/IP, PROFINET, and Modbus TCP, making it ideal for integrating ABB robots into hybrid automation environments alongside third-party devices from brands like Rockwell or Siemens.

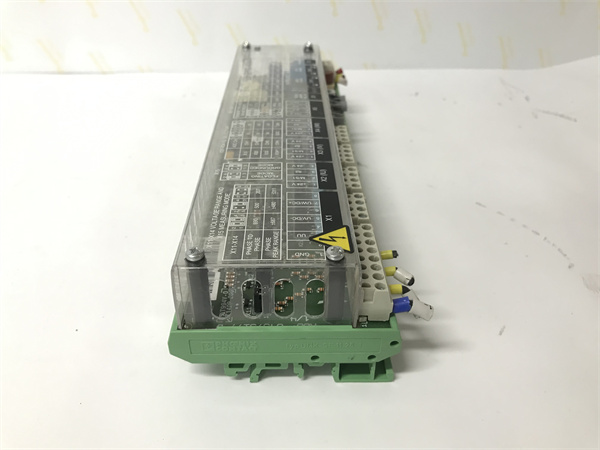

Engineered with a dual-core processor and advanced data buffering capabilities, the NAMU-01C 64702475D ensures low-latency communication (≤1 ms cycle time) even in high-data-rate applications, such as collaborative robotics or high-speed pick-and-place systems. Its compact design (100 mm × 80 mm × 50 mm) and rugged construction (IP20 rating) allow seamless integration into robot 控制柜 (control cabinets) or distributed I/O racks, while the 64702475D firmware variant enhances compatibility with ABB’s RobotStudio® software for intuitive configuration and diagnostics. Positioned as a scalable solution, the module reduces complexity in Industry 4.0 setups by consolidating multiple network protocols into a single unit, enabling real-time OEE (Overall Equipment Effectiveness) tracking and predictive maintenance for robotic fleets.

| Parameter Name |

Parameter Value |

| Product Model |

NAMU-01C 64702475D |

| Manufacturer |

ABB |

| Product Type |

Industrial Network Adapter Module |

| Communication Protocols |

Ethernet/IP, PROFINET, Modbus TCP, EtherCAT (optional) |

| Data Rate |

10/100/1000 Mbps (auto-negotiation) |

| Latency |

≤1 ms (real-time control data) |

| Supported Systems |

ABB IRC5 Robot Controllers, AC 800M PLCs |

| Power Supply |

24 V DC (±10%, 150 mA) |

| Operating Temperature |

0°C to +50°C |

| Dimensions (W×H×D) |

100 mm × 80 mm × 50 mm |

| Mounting Method |

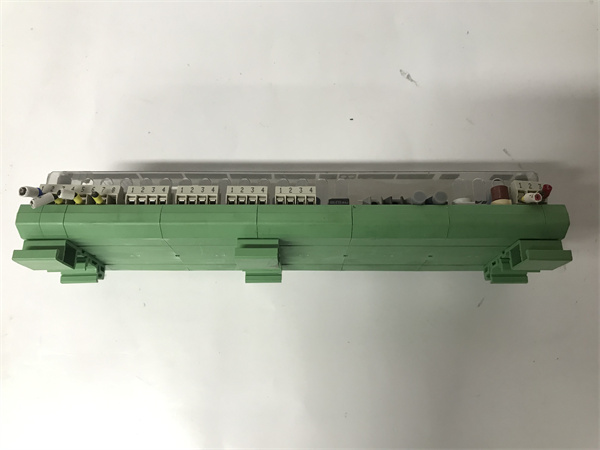

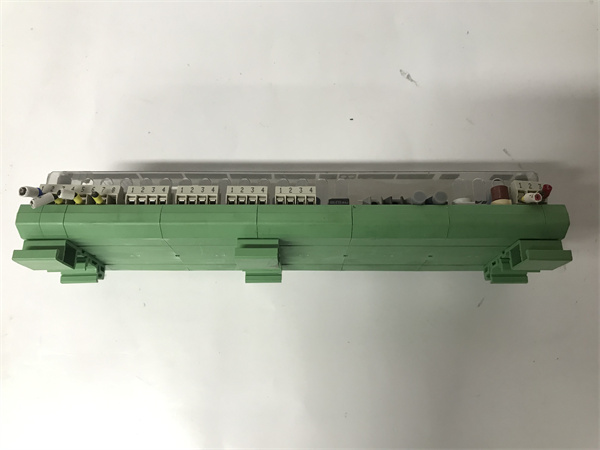

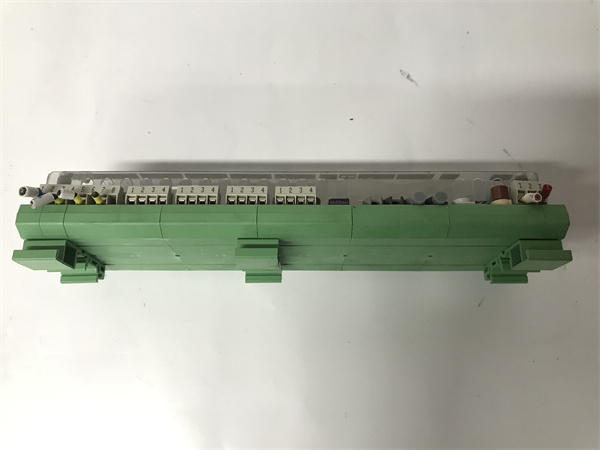

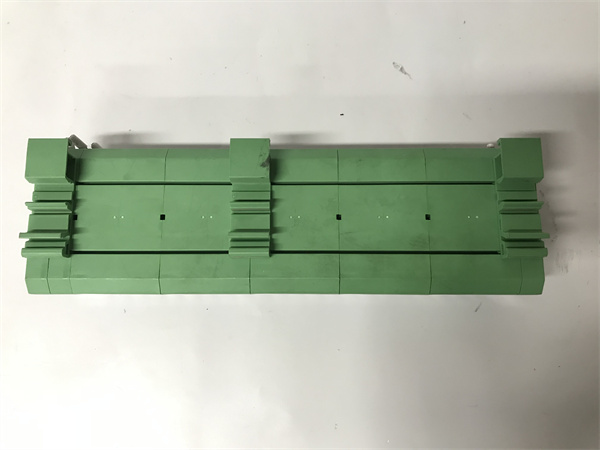

DIN rail or panel-mounted (M4 screws) |

| Certification |

CE, UL, IEC 61131-2, RoHS |

| Diagnostic Features |

LED indicators (link/activity, error), web-based status monitor |

NAMU-01C 64702475D

The NAMU-01C 64702475D eliminates the need for multiple dedicated gateways by supporting simultaneous communication across Ethernet/IP, PROFINET, and Modbus TCP. For example, in an automotive assembly line, the module can transmit real-time robot position data to a Rockwell PLC via Ethernet/IP while receiving production schedules from a Siemens SCADA system via PROFINET, all within a single interface. This flexibility reduces hardware costs by up to 30% and simplifies inventory management in mixed-vendor environments.

With its time-sensitive networking (TSN) capabilities, the module ensures deterministic data delivery for critical applications like robot coordination in pharmaceutical packaging lines, where microsecond-level precision is required to avoid product contamination. The 64702475D firmware includes built-in redundancy protocols (HSR/PRP), enabling seamless failover between network paths in the event of cable or switch failures, which is vital for 24/7 operations in food processing plants or semiconductor fabs.

The module integrates with ABB’s

RobotStudio® software, allowing engineers to configure IP addresses, map data tags, and monitor network health through a unified interface. Its web-based diagnostic portal provides real-time insights into packet loss, latency trends, and protocol-specific errors, enabling rapid troubleshooting without physical access to the robot cell. In a logistics warehouse using ABB’s IRB 1200 robots, the

NAMU-01C 64702475D enables remote operators to reconfigure gripper control parameters via Ethernet/IP, reducing changeover time between product lines by 50%.

NAMU-01C 64702475D

The ABB NAMU-01C 64702475D is essential in industries driving robotic automation and digital transformation:

- Automotive Manufacturing: Integrates ABB robots with body-in-white welding cells, enabling real-time coordination between robots and PLCs to achieve ±0.1 mm positional accuracy in car body assembly. The module’s PROFINET compatibility ensures seamless integration with Siemens’ Simatic controllers commonly used in automotive plants.

- Pharmaceutical Packaging: Supports high-speed pick-and-place robots in blister packaging lines, where Ethernet/IP connectivity transmits real-time rejection rates from vision systems to the robot controller, adjusting pick positions dynamically to minimize waste. The module’s compact design fits within sterile cabinet environments.

- Electronics Assembly: Enables collaborative robots (cobots) to communicate with pick-and-place machines via Modbus TCP in PCB assembly lines, ensuring precise placement of micro-components (≤0402 size) with zero defects. The module’s low latency (≤1 ms) is critical for maintaining synchronization with high-speed conveyors.

- Warehouse Automation: Connects AGVs (Automated Guided Vehicles) based on ABB’s IRB 1300 robots to warehouse management systems (WMS) via Ethernet/IP, optimizing route planning and pallet handling in distribution centers. The module’s rugged design withstands the vibration and dust of logistics environments.

- ABB NAMU-02D 64702476E: An upgraded variant with dual Ethernet ports and TSN support, ideal for high-reliability networks in aerospace manufacturing.

- ABB DSQC 377A: A PROFINET interface module for older IRC5 controllers, serving as a legacy-compatible alternative to the NAMU-01C.

- ABB CI527: A Modbus TCP gateway module for ABB’s AC 800M PLC, complementary to the NAMU-01C in hybrid PLC-robot systems.

- ABB 800xA Connectivity Gateway: A software solution that enhances the NAMU-01C’s compatibility with cloud platforms like AWS IoT, enabling predictive maintenance for robotic fleets.

- ABB TB511: A terminal block accessory for secure field wiring, used with the module’s analog/digital extension ports in custom automation setups.

Pre-installation preparation: Ensure the robot controller or PLC cabinet is properly grounded and has sufficient airflow (≥0.5 m/s) to maintain optimal operating temperature. Mount the NAMU-01C 64702475D on a DIN rail using the provided brackets, ensuring at least 25 mm of clearance between modules for heat dissipation. Connect Ethernet cables using shielded Cat6a patch cords, terminating them to the module’s RJ45 ports with proper strain relief. Configure the module’s IP address and subnet mask via RobotStudio® or the web interface, verifying compatibility with the plant’s network architecture.

Maintenance recommendations: Inspect the module’s LED indicators monthly to confirm network connectivity (green for link/activity, amber for errors). In dusty environments (e.g., tire manufacturing), clean the module’s vents with compressed air every quarter to prevent dust accumulation that could affect thermal performance. Update firmware annually via ABB’s RobotWare software to access new protocol updates or security patches. If network latency issues arise, use the module’s built-in ping tool to identify faulty cables or switches, replacing components promptly to maintain real-time performance.

ABB stands behind the NAMU-01C 64702475D with a 3-year warranty, covering defects in materials, firmware, and workmanship. ABB’s global technical support team provides 24/7 remote assistance for network configuration, firmware updates, and fault diagnosis, ensuring minimal downtime in critical production lines. The module’s compliance with IEC 61131-2 and UL 508 standards guarantees compatibility with global industrial safety requirements. For customers in regulated industries, ABB offers Validation Services to ensure the module meets specific compliance needs, such as FDA 21 CFR Part 11 for pharmaceutical applications. By combining robust connectivity, real-time performance, and ease of management, the NAMU-01C 64702475D delivers unmatched value as the backbone of intelligent robotic automation systems.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide