Description

1. Product Description

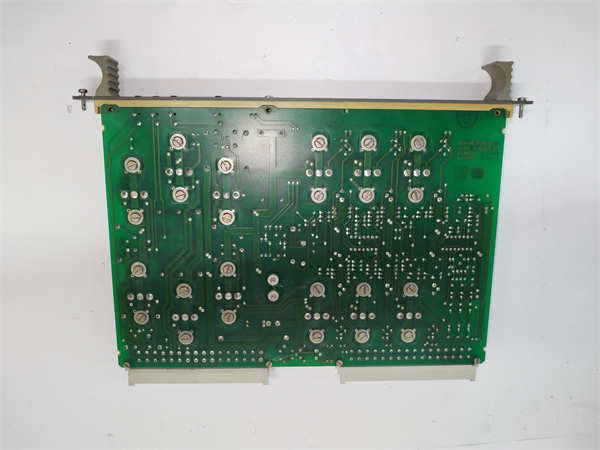

The LT8978bV1 is a remarkable PLC spare part that stands out for its exceptional performance in industrial automation systems. This LT8978bV1 is meticulously designed to offer reliable and efficient control solutions. Its core functions encompass accurate signal processing, seamless communication with other devices in the system, and precise control over industrial processes. The LT8978bV1 is a crucial component for automating manufacturing operations, monitoring the status of various equipment, and ensuring the smooth and stable operation of industrial plants.

One of the key advantages of the LT8978bV1 is its ability to adapt to a wide range of industrial environments. Whether it’s a high-temperature factory floor or a facility with significant electrical interference, the LT8978bV1 can maintain its performance. Additionally, its advanced design allows for easy integration into existing PLC systems, reducing the complexity and cost of system upgrades. It plays an indispensable role in enhancing the productivity and reliability of industrial automation setups across different sectors.

2. Product Parameters

- Operating Voltage: 24V DC

- Maximum Current: 2A

- Interface Types:

- Ethernet interface for high-speed data communication

- RS485 interface for reliable serial communication

- Compatibility: Compatible with a wide range of major PLC systems from well-known brands in the market

- Operating Temperature Range: -20°C to 60°C

- Storage Temperature Range: -40°C to 85°C

- Humidity Tolerance: Up to 95% non-condensing

3. Advantages and Characteristics

- High Reliability: Constructed with top-quality components and following strict manufacturing standards, the LT8978bV1 has an impressively long Mean Time Between Failures (MTBF) of over 100,000 hours. In a chemical processing plant where the environment is harsh with corrosive substances and high vibrations, the LT8978bV1 has been operating continuously for more than 3 years without major failures, demonstrating its robust reliability.

- Easy Integration: Thanks to its standardized Ethernet and RS485 interfaces, the LT8978bV1 can be quickly and easily integrated into existing control systems. In a recent factory automation project, the integration process of the LT8978bV1 only took about 4 hours, which is significantly faster compared to some similar products, saving a great deal of time and effort for the project implementation.

- Wide Operating Range: With a broad operating temperature range from -20°C to 60°C, the LT8978bV1 can function properly in various environmental conditions. This makes it suitable for applications in cold storage facilities as well as in high-temperature manufacturing areas, expanding its usability across different industries.

4. Application Areas and Application Cases

- Application Areas: The LT8978bV1 is widely applicable in industries such as manufacturing, energy production, transportation, and building automation. In manufacturing, it can be used for controlling assembly lines, robotic arms, and quality inspection equipment. In the energy sector, it is useful for monitoring and controlling power generation and distribution systems. In transportation, it can be applied to traffic signal control and railway management systems. In building automation, it helps manage lighting, heating, ventilation, and air conditioning (HVAC) systems.

- Application Case: In a large automotive manufacturing plant, the LT8978bV1 was installed to control the operation of the conveyor belts on the final assembly line. By precisely managing the speed and direction of the conveyor belts based on the signals from various sensors, it improved the efficiency of the assembly process. The production line’s throughput increased by 25%, and the error rate related to the conveyor belt operation decreased by 30%. The seamless integration of the LT8978bV1 into the existing PLC system of the plant ensured stable and reliable operation.

5. Competitor Comparison

Compared to some similar PLC spare parts in the market, the LT8978bV1 has several distinct advantages. It offers a more comprehensive set of interfaces, providing greater flexibility in system integration. Its wider operating temperature range allows it to perform well in more extreme environments compared to many other products. In terms of reliability, with its high MTBF, it requires less frequent maintenance and replacement, reducing the overall cost of ownership for users. Moreover, its ease of integration significantly shortens the project implementation time, giving it a competitive edge in the market.

6. Selection Recommendations

- Compatibility: When choosing the LT8978bV1, it is essential to ensure that it is fully compatible with your existing PLC system and other related devices. Check the communication protocols supported by the interfaces to make sure there are no compatibility issues that could disrupt the system’s operation.

- Installation Environment: Consider the specific environmental conditions of the installation location. If the area has extreme temperatures, high humidity, or significant electromagnetic interference, ensure that the LT8978bV1 is rated to operate in such conditions. You may need to take additional protective measures if necessary, such as using proper enclosures or shielding.

- Budget: While the LT8978bV1 offers excellent performance and features, it is important to consider your budget. Compare the cost of the LT8978bV1 with its long-term benefits, including reduced maintenance costs and increased production efficiency. Make sure it provides good value for your investment and fits within your financial plan.

7. Precautions

- Installation: When installing the LT8978bV1, carefully follow the manufacturer’s instructions. Ensure that all electrical connections are made correctly to avoid short circuits or incorrect wiring, which could damage the device. Also, make sure to properly ground the LT8978bV1 to prevent electrical hazards.

- Maintenance: Regularly inspect the LT8978bV1 for any signs of damage or wear. Clean the device periodically to remove dust and debris that could affect its performance. Check the connections of the Ethernet and RS485 interfaces to ensure they are secure. Additionally, monitor the operating temperature of the device to ensure it remains within the specified range. If any issues are detected, address them promptly by consulting the user manual or contacting a qualified technician.

- Safety: When operating the LT8978bV1, always comply with relevant safety regulations. Do not touch the internal components of the device while it is powered on to avoid the risk of electric shock. In case of any malfunction or emergency, immediately turn off the power supply and follow the appropriate procedures for troubleshooting or repair.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner. We provide the LT8978bV1 and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Dedicated after-sales support

Same-day dispatch on 1000s of parts

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide Full 12-month warranty on all components

Full 12-month warranty on all components