Description

The

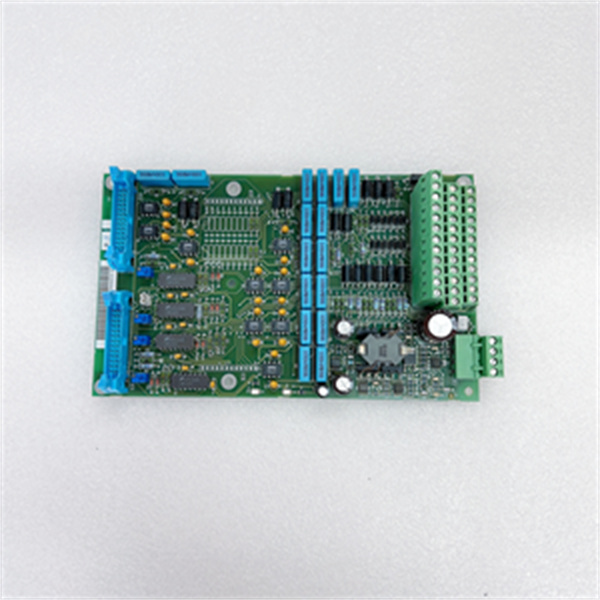

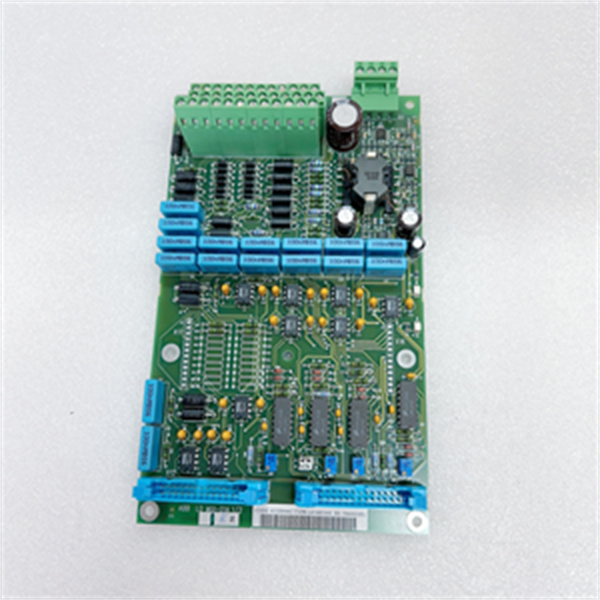

ABB LDMUI-001 61320946C is a high-performance

level detection and monitoring interface module designed for industrial process control systems, specifically engineered to integrate with ABB’s distributed control systems (DCS) and programmable logic controllers (PLCs). As part of ABB’s

Level and Pressure Measurement Portfolio, the

LDMUI-001 61320946C serves as a critical link between level sensors (e.g., radar, ultrasonic, or hydrostatic sensors) and the control system, enabling real-time 液位 (liquid level) data acquisition, alarm generation, and closed-loop control in industries such as oil & gas, chemical processing, and water treatment.

Featuring 4 isolated input channels, the LDMUI-001 61320946C supports standard industrial signals (4–20 mA, 0–10 V) from various level sensors, with built-in signal conditioning and linearization algorithms to ensure accuracy within ±0.1% of full scale. The 61320946C variant includes enhanced EMC immunity (EN 61000-6-2/4) and a rugged IP20 enclosure, making it suitable for harsh environments with high electromagnetic interference or mechanical vibration. Its modular design allows seamless integration into ABB’s AC 800M control platform, where it can be configured via Control Builder M software to support complex 液位 control strategies, such as multi-tank cascade control or pump sequencing based on real-time level data. Positioned as a reliable and scalable solution, the module optimizes process efficiency by reducing manual monitoring efforts and minimizing the risk of overfill or dry-run incidents.

| Parameter Name |

Parameter Value |

| Product Model |

LDMUI-001 61320946C |

| Manufacturer |

ABB |

| Product Type |

Level Detection Interface Module |

| Input Channels |

4 isolated channels |

| Signal Types |

4–20 mA, 0–10 V (software-configurable) |

| Accuracy |

±0.1% of full scale |

| Resolution |

16-bit ADC |

| Communication Protocol |

Profibus DP, Modbus RTU (via gateway) |

| Power Supply |

24 V DC (±10%, 80 mA) |

| Operating Temperature |

-25°C to +60°C |

| Dimensions (W×H×D) |

100 mm × 120 mm × 60 mm |

| Mounting Method |

DIN rail (AC 800M I/O rack) |

| Certification |

CE, UL, IEC 61131-2, RoHS |

| Alarm Outputs |

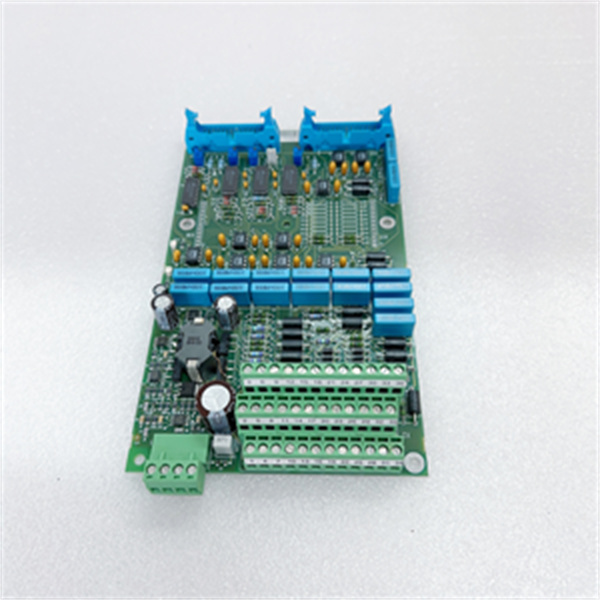

2 dry contact relays (SPDT, 5 A/250 V AC) |

LDMUI-001 61320946C

The LDMUI-001 61320946C ensures reliable 液位 data acquisition with auto-calibration and drift compensation, eliminating the need for frequent manual adjustments. For example, in a chemical reactor, the module can linearize non-linear radar sensor outputs to provide accurate level readings, even for complex fluid profiles (e.g., foaming liquids). The module’s channel redundancy support (when paired with ABB’s redundant I/O backplane) ensures continuous operation in critical applications like nuclear power plant cooling systems, where a single channel failure would otherwise trigger a shutdown.

With its user-friendly web interface and integration with ABB’s 800xA software, the LDMUI-001 61320946C simplifies configuration of alarm thresholds, data logging intervals, and control logic. Engineers can set up high/low level alarms with adjustable deadbands, such as triggering a pump shutdown when a storage tank reaches 90% capacity while ignoring minor level fluctuations. Built-in diagnostics provide real-time insights into sensor health (e.g., open circuit, signal dropout), reducing mean time to detect (MTTD) faults by 50% compared to legacy systems. In a water treatment plant, this feature helps operators quickly identify a faulty ultrasonic sensor before it impacts water supply continuity.

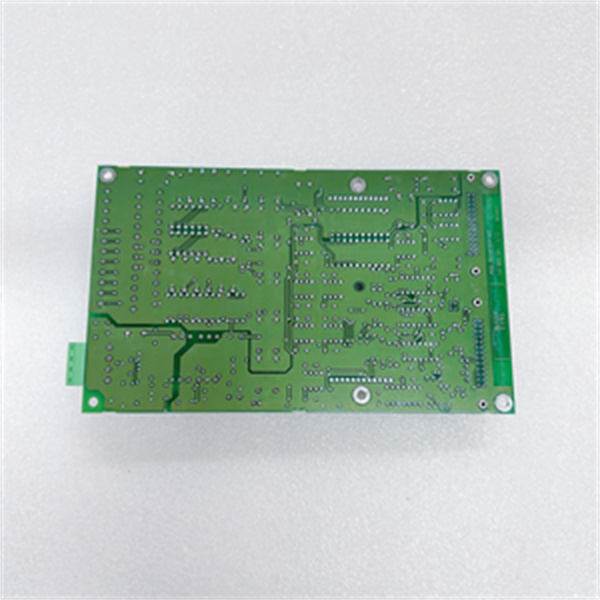

The module’s conformal-coated PCBs and stainless-steel terminal blocks protect against moisture, dust, and corrosive gases, making it suitable for offshore platforms or wastewater treatment facilities. Its wide temperature range (-25°C to +60°C) supports installations in both arctic and tropical climates, such as monitoring fuel tank levels in remote oil fields or cooling tower water levels in desert power plants. The 61320946C variant’s enhanced surge protection (2 kV) safeguards against transient voltage spikes from lightning strikes or motor startups, a critical advantage in outdoor installations.

The ABB LDMUI-001 61320946C is essential in industries where precise 液位 control is vital for safety and efficiency:

- Oil and Gas: Monitors crude oil storage tanks, separator vessels, and offshore ballast tanks. In a floating production storage and offloading (FPSO) vessel, the module ensures accurate level measurements despite vessel motion, preventing overfill during loading operations.

- Chemical Processing: Controls 液位 in reactors, distillation columns, and hazardous material storage tanks. The module’s alarm outputs can trigger emergency relief valves or inert gas injection systems in the event of unexpected level surges, mitigating risks of chemical spills or explosions.

- Water and Wastewater: Manages 液位 in clarifiers, sedimentation tanks, and stormwater retention basins. In a smart city’s wastewater network, the LDMUI-001 61320946C coordinates pump operations based on real-time 液位 data, optimizing energy use and preventing sewer overflows during heavy rainfall.

- Food and Beverage: Ensures hygienic 液位 control in mixing tanks, pasteurization systems, and bottling lines. The module’s compatibility with hygienic sensors (e.g., sanitary flanged ultrasonic sensors) meets FDA and EHEDG standards for food safety, such as monitoring milk storage levels in dairy plants.

LDMUI-001 61320946C

- ABB LDMUI-002 61320947D: A 8-channel variant for large-scale systems, ideal for refineries or bulk storage terminals requiring high-density 液位 monitoring.

- ABB LDG-100: A radar level sensor commonly paired with the LDMUI-001, offering non-contact 液位 measurement for challenging media (e.g., corrosive liquids, high-temperature fluids).

- ABB PM866AK01: An AC 800M control module that processes 液位 data from the LDMUI-001 and executes control logic, such as adjusting pump speeds or valve positions based on level setpoints.

- ABB CI522: A Profibus DP interface module, enabling the LDMUI-001 to communicate with third-party PLCs or SCADA systems in hybrid automation environments.

- ABB TB521: A terminal block accessory for secure sensor wiring, compatible with the module’s analog input channels, ensuring reliable connections in high-vibration applications like mining conveyors.

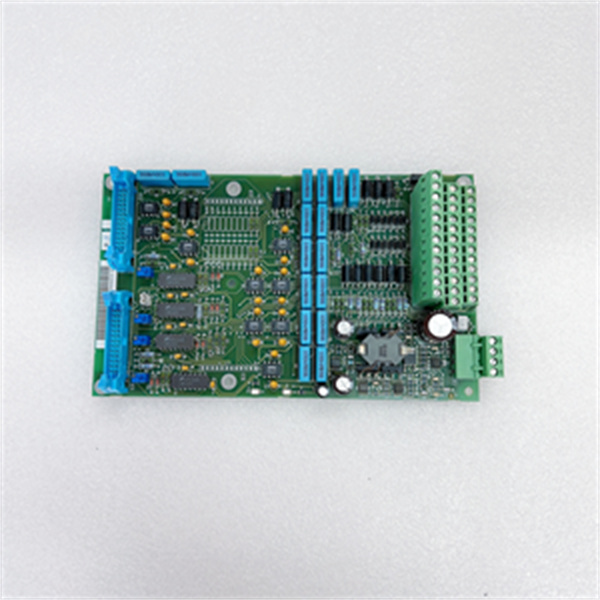

Pre-installation preparation: Mount the LDMUI-001 61320946C on a DIN rail in a control cabinet, ensuring proper grounding and ventilation. Connect sensor cables using shielded twisted-pair wiring, terminating them to the TB521 terminal block with specified torque (2.5 N·m). Configure signal types, scaling factors, and alarm settings via Control Builder M or the module’s web interface, verifying compatibility with the sensor’s output range (e.g., 4–20 mA for a hydrostatic level transmitter).

Maintenance recommendations: Inspect the module’s LED indicators monthly to confirm power status and channel activity. In dusty environments (e.g., grain silos), clean the ventilation slots quarterly with compressed air to prevent thermal derating. Use the module’s built-in self-test function annually to verify ADC accuracy and relay functionality, simulating high/low level conditions to ensure alarm outputs trigger correctly. Update firmware via the AC 800M’s firmware manager to access new sensor compatibility or security patches, particularly in regulated industries like pharmaceuticals.

ABB stands behind the LDMUI-001 61320946C with a 5-year warranty, covering defects in materials, firmware, and workmanship. ABB’s global technical support team provides 24/7 remote diagnostics and on-site assistance, ensuring rapid resolution of issues in critical 液位 control systems. The module’s compliance with IEC 61131-2 and ISO 9001 standards guarantees consistent quality, while its rigorous testing (e.g., 10,000-hour continuous operation tests) ensures reliability in 24/7 environments. For customers in safety-critical sectors, ABB offers Functional Safety Assessment Services to validate the module’s suitability for SIL 2 applications, such as chemical plant emergency shutdown systems. By combining precision measurement, rugged design, and seamless integration, the LDMUI-001 61320946C delivers unmatched value as a backbone for industrial 液位 automation.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide