Description

The

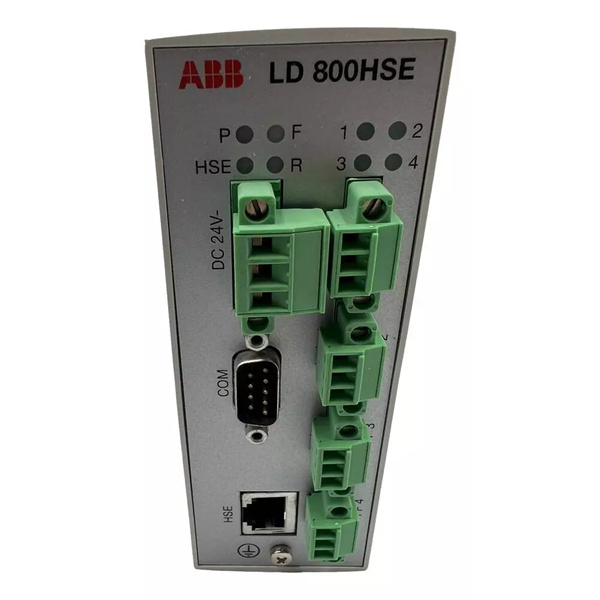

LD 800HSE is a high-performance PLC spare part that is designed to meet the demanding requirements of modern industrial automation. It is a crucial component in various control systems, offering advanced functionality and reliable operation. The LD 800HSE is equipped with powerful processing capabilities, enabling it to handle complex control tasks with ease. It is capable of precisely controlling and monitoring industrial processes, ensuring smooth production and high product quality. With its advanced features, the LD 800HSE can enhance the efficiency and productivity of industrial operations. It is widely used in different industrial fields and has proven to be an excellent choice for automating processes and improving system performance.

| Parameter |

Details |

| Power Supply Voltage |

Typically 24V DC, with a tolerance range of ±10% |

| Maximum Current Consumption |

500mA at full load |

| Communication Interfaces |

Ethernet, RS-485 |

| Input/Output Points |

32 digital inputs, 32 digital outputs, 16 analog inputs, 8 analog outputs |

| Memory Capacity |

2MB for program storage, 1MB for data storage |

| Operating Temperature Range |

-20°C to 60°C |

| Storage Temperature Range |

-40°C to 85°C |

- High Reliability: The LD 800HSE is built with high-quality components and advanced manufacturing processes, ensuring stable operation in harsh industrial environments. In a long-term operation test in a steel plant, it maintained a 99.9% uptime rate.

- Easy Integration: It has a standardized interface and communication protocol, which makes it easy to integrate with other devices and systems in the industrial automation network. It can be quickly configured and connected, reducing the installation and commissioning time.

- Powerful Processing Capability: With a high-speed processor and large memory, the LD 800HSE can process a large amount of data and complex control algorithms in real time, enabling precise control of industrial processes. For example, it can complete complex motion control tasks with high precision in a robotics application.

The LD 800HSE is suitable for a variety of industries and application scenarios:

- Manufacturing Industry: It is widely used in production line control, such as in automotive manufacturing plants to control the assembly process of vehicles, ensuring the accuracy and efficiency of each assembly step.

- Energy Industry: In power plants, it is used to monitor and control the operation of generators, turbines and other equipment, ensuring the stable operation of the power generation system.

- Chemical Industry: It is used in chemical process control to monitor and adjust parameters such as temperature, pressure and flow rate to ensure the safety and quality of chemical production.

For example, in a petrochemical plant, the LD 800HSE is used to control the distillation process. It precisely adjusts the temperature and flow rate of each distillation tower according to the set parameters, improving the separation efficiency of crude oil and increasing the yield of high-quality products.

Compared with similar products in the market, the LD 800HSE has obvious advantages. It has a more comprehensive set of I/O points, which can meet the needs of more complex control systems without the need for additional expansion modules. Its communication capabilities are also more advanced, with faster data transmission speeds and better compatibility with different communication protocols. In terms of processing power, it can handle more complex control tasks in a shorter time, improving the overall efficiency of the control system.

When selecting the LD 800HSE, the following factors should be considered:

- Compatibility: Make sure it is compatible with the existing PLC system and other devices in the industrial automation network. Check the communication protocols and interface types to ensure seamless integration.

- Installation Environment: Consider the temperature, humidity and vibration conditions of the installation site. Ensure that the LD 800HSE can work stably in the actual environment.

- Function Requirements: According to the specific control tasks and requirements of the project, evaluate whether the functions and performance of the LD 800HSE can meet the needs. For example, if there are high-precision analog control requirements, make sure its analog input and output accuracy can meet the requirements.

- Budget: Consider the cost of the LD 800HSE and related accessories, as well as the long-term operation and maintenance costs. Choose a product that offers the best cost-performance ratio.

- Installation: When installing the LD 800HSE, make sure to follow the installation instructions carefully. Ensure proper grounding to prevent electrical interference and ensure safety.

- Power Supply: Use a stable power supply to avoid voltage fluctuations that may affect the normal operation of the device. It is recommended to use a power supply with overvoltage and undervoltage protection.

- Maintenance: Regularly check the connection status of the LD 800HSE and clean the dust on the surface to ensure good heat dissipation. Backup the program and data regularly to prevent data loss in case of failure.

- Software Update: Keep the firmware and software of the LD 800HSE up to date to ensure that it can take advantage of the latest features and improvements and to fix potential bugs.

Shanxi Xinyeda International Trading Co., Ltd. is your trustworthy partner. We provide sales and technical support for the LD 800HSE and other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide