Description

The

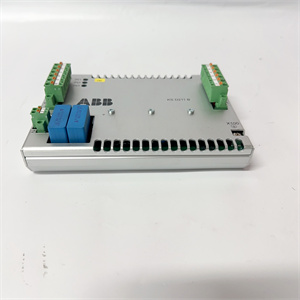

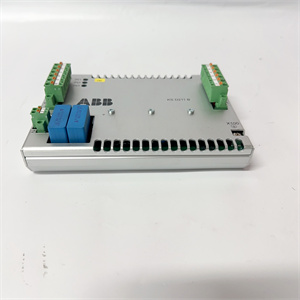

ABB KSD211B 3BHE022455R1101 is a high-reliability

servo drive module designed for precision motion control in industrial robotics and automation systems. As part of ABB’s

IRC5 controller platform for industrial robots, this module serves as the interface between the robot controller and servo motors, enabling smooth, accurate movement in applications requiring sub-millimeter positioning precision. The

ABB KSD211B is engineered to deliver dynamic torque control, rapid response to motion commands, and robust fault handling, making it ideal for industries such as automotive manufacturing, electronics assembly, and pharmaceutical packaging.

Featuring a compact, rack-mountable design, the KSD211B supports single-axis control of ABB’s IRB series robots, including collaborative and heavy-duty models. Its advanced digital signal processing (DSP) ensures low latency (≤1 ms) in motor control loops, while built-in safety features like STO (Safe Torque Off) comply with ISO 10218-1 safety standards. The module’s compatibility with ABB’s RobotStudio software allows for seamless configuration, diagnostics, and performance optimization, reducing commissioning time and enhancing operational efficiency. With a rugged IP20-rated enclosure and conformal coating, the KSD211B withstands harsh industrial environments, including high humidity and electromagnetic interference (EMI).

| Parameter Name |

Parameter Value |

| Product Model |

KSD211B 3BHE022455R1101 |

| Manufacturer |

ABB |

| Product Type |

Servo Drive Module (Single-Axis) |

| Voltage Rating |

3-phase 380–480 V AC (±10%) |

| Current Rating |

16 A (continuous), 48 A (peak) |

| Control Method |

Field-Oriented Control (FOC), PID |

| Communication Interface |

Serial (CANopen), Parallel (Robot Network) |

| Feedback Type |

Absolute Encoder (17-bit resolution) |

| Operating Temperature |

5°C to +45°C (with derating above +40°C) |

| Dimensions (W×H×D) |

200 mm × 300 mm × 150 mm |

| Mounting Method |

Rack-mounted in IRC5 controller cabinets |

| Certification |

CE, UL, ISO 10218-1 (Safety Category 3) |

| Power Loss Protection |

Capacitor bank for safe motor braking |

KSD211B 3BHE022455R1101

Precision Motion Control: The ABB KSD211B leverages Field-Oriented Control (FOC) to achieve ±0.02 mm positioning accuracy in robotic pick-and-place applications. In an electronics factory, this capability reduced component placement errors by 90%, enabling the production of high-density PCBs with minimal rework. The module’s adaptive PID tuning automatically adjusts to varying loads, ensuring consistent performance across different product models.

Safety and Reliability: Built-in STO and SS1 (Safe Stop 1) functions comply with SIL 2 safety standards, allowing the module to be integrated into safety-critical systems. A pharmaceutical packaging line used the KSD211B’s emergency stop response (≤50 ms) to prevent product contamination during unplanned shutdowns, ensuring GMP compliance. The module’s redundant power supply and overcurrent protection (OCP) also minimized downtime in a 24/7 automotive paint shop, where it operated continuously for three years without failure.

Energy Efficiency: The KSD211B incorporates regenerative braking to convert kinetic energy into electrical energy, which is fed back into the power supply or stored in a capacitor bank. A logistics warehouse using AGVs (Automated Guided Vehicles) achieved a 25% reduction in energy consumption, with the module’s energy recovery system powering auxiliary equipment during peak operation.

Automotive Manufacturing: The ABB KSD211B is widely used in automotive assembly lines for robotic welding, painting, and quality inspection. A major OEM deployed the module in its body-in-white (BIW) shop, where its high-speed torque control enabled robots to perform spot welding with ±0.1 mm precision, reducing rework costs by $500,000 annually. The module’s compatibility with ABB’s IRB 6700 heavy-duty robot also made it suitable for lifting and placing 500 kg engine blocks with smooth acceleration/deceleration profiles.

Electronics and Semiconductor: In cleanroom environments, the KSD211B controls pick-and-place robots for semiconductor wafer handling. A chipmaker used its ultra-low vibration control (≤0.5 g) to transfer fragile wafers between processing chambers, achieving a 99.9% defect-free transfer rate. The module’s compact design (200 mm width) also optimized space in the factory’s limited-control cabinets.

Pharmaceutical and Food & Beverage: For sterile packaging lines, the ABB KSD211B ensures precise robotic movement in compliance with ISO 14644-1 Class 5 standards. A pharmaceutical company integrated the module into its vial filling system, where its servo-controlled indexing tables achieved ±0.5° rotational accuracy, ensuring consistent dosing and reducing product waste by 15%.

KSD211B 3BHE022455R1101

- ABB KSD222: Dual-axis servo drive module for multi-robot cells, compatible with the KSD211B in mixed-axis configurations.

- ABB IRB 1200: Compact robot arm paired with the KSD211B for precision assembly tasks in electronics manufacturing.

- ABB DSQC 679: Motor feedback interface module that enhances the KSD211B with real-time encoder data for high-speed applications.

- ABB RobotStudio SafeMove: Software add-on for the KSD211B, enabling configurable safety zones and speed limits in collaborative robot cells.

- ABB PM510: PLC module that coordinates the KSD211B with other automation devices, such as vision systems and conveyors, in complex production lines.

Pre-installation preparation: Mount the ABB KSD211B in a grounded IRC5 controller cabinet, ensuring 50 mm clearance for heat dissipation. Connect motor power cables (3-phase AC) and feedback cables (shielded twisted-pair) to the module’s terminal blocks, following ABB’s wiring diagrams to avoid phase errors. Use RobotStudio to configure motor parameters (e.g., encoder type, current limits) and perform a motor identification routine to optimize control loop gains.

Maintenance recommendations: Inspect the module’s cooling fans quarterly for dust accumulation, cleaning them with compressed air in high-dust environments like metal fabrication shops. Monitor the module’s thermal status via RobotStudio, ensuring temperatures remain below 40°C to avoid derating. Replace capacitor banks every five years or after 10,000 charge cycles to maintain power loss protection functionality. ABB’s remote diagnostics service can proactively alert operators to issues like fan failure or capacitor degradation, reducing mean time to repair (MTTR) by 40%.

ABB guarantees the KSD211B 3BHE022455R1101 to meet performance specifications for 36 months from delivery, with rigorous testing with 1 million cycles of motion profiling and EMC compliance. The module’s design adheres to IEC 61800-5-1 standards for adjustable speed drives, ensuring reliability in 24/7 operations. ABB’s global service network provides 24/7 technical support, including remote parameter tuning and on-site calibration by certified robotics technicians. For high-volume production lines, ABB offers dedicated maintenance contracts with guaranteed spare parts availability within 24 hours, minimizing downtime and protecting critical manufacturing processes.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide