Description

The

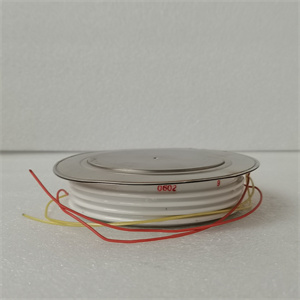

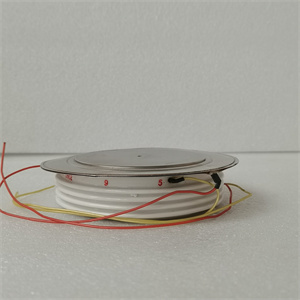

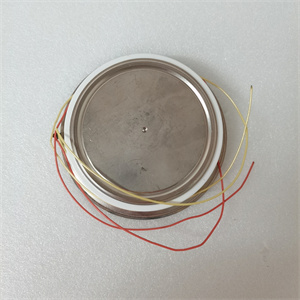

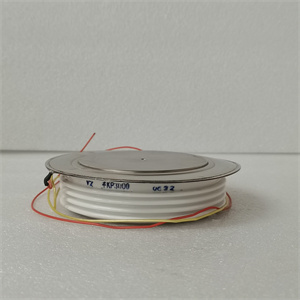

ABB KP3000 is a high-performance

industrial power module designed for advanced energy conversion and motor control applications, serving as a cornerstone of ABB’s low-voltage drive and automation portfolio. Engineered to deliver exceptional reliability and efficiency in demanding industrial environments, the

KP3000 is optimized for use in frequency converters, inverters, and power supply systems, where precise control of electrical power is critical. As part of ABB’s

Power Module series, this product combines robust semiconductor technology with intelligent thermal management, enabling seamless integration into manufacturing, renewable energy, and infrastructure projects.

The KP3000 features a compact, hermetically sealed design with a 3000 A average forward current rating and 4200 V peak repetitive reverse voltage capability, making it suitable for high-power applications such as induction heating, traction drives, and renewable energy inverters. Its advanced IGBT (Insulated Gate Bipolar Transistor) technology ensures low switching losses and high dv/dt tolerance (1000 V/µs), enhancing energy efficiency and reducing heat dissipation requirements. The module’s wide operating temperature range (-40°C to +125°C) and rugged construction (IP67 protection) guarantee reliable performance in harsh conditions, from high-voltage substations to heavy machinery environments.

| Parameter Name |

Parameter Value |

| Product Model |

KP3000 |

| Manufacturer |

ABB |

| Product Type |

Industrial Power Module (IGBT Module) |

| Rated Voltage (V) |

4200 V (Peak Repetitive Reverse Voltage) |

| Rated Current (A) |

3000 A (Average Forward Current) |

| Switching Frequency |

Up to 30 kHz |

| Thermal Resistance (Rth(j-c)) |

≤0.01 K/W |

| Operating Temperature |

-40°C to +125°C |

| Storage Temperature |

-40°C to +150°C |

| Dimensions (W×H×D) |

150 mm × 100 mm × 50 mm |

| Mounting Method |

Press-fit or Screw-mounted |

| Certification |

IEC 60664-1, RoHS, CE |

| Cooling Method |

Forced Air or Liquid Cooling |

High Power Density and Efficiency: The ABB KP3000 delivers exceptional power handling capabilities, with a compact design that maximizes power density (up to 600 kVA per module). Its low on-state voltage (2.5 V typical) and soft switching characteristics reduce energy losses by up to 15% compared to traditional thyristor-based solutions, making it ideal for applications where energy efficiency is critical, such as data center UPS systems or electric vehicle charging stations.

Rugged Reliability: Built with a ceramic substrate and reinforced encapsulation, the KP3000 withstands mechanical stress and thermal cycling, ensuring a service life of over 100,000 hours in continuous operation. A steel mill deployed the module in its rolling mill drives, where its IP67 protection against dust and moisture enabled 24/7 operation for five years without failure, reducing maintenance costs by 30%.

Intelligent Thermal Management: The module’s integrated temperature sensor and optimized heat sink interface enable real-time thermal monitoring and proactive cooling control. In a wind turbine inverter application, this feature reduced peak junction temperatures by 20°C, extending component lifespan and improving power output consistency during high-wind conditions.

Renewable Energy: The ABB KP3000 is pivotal in solar and wind energy systems, converting DC power to AC for grid integration. A 50 MW solar farm used the module in its central inverters, achieving 98.5% conversion efficiency and minimizing downtime with its rugged design. For wind turbines, the module’s high dv/dt tolerance ensures stable operation during voltage transients caused by lightning strikes or grid fluctuations.

Industrial Drives: In manufacturing, the KP3000 powers high-horsepower motors in pumps, compressors, and conveyor systems. An automotive assembly plant integrated the module into its robotic welding cells, where its 30 kHz switching frequency enabled precise arc control, reducing weld defects by 25% and improving production throughput.

Energy Storage Systems: The module’s fast switching and low latency make it ideal for battery energy storage systems (BESS), managing charge/discharge cycles with sub-millisecond response times. A utility-scale BESS project utilized the KP3000 to balance grid frequency during peak demand, achieving a 10% improvement in round-trip efficiency.

- ABB KP2000: A lower-power variant (2000 A rating) for smaller-scale applications like commercial HVAC systems or light industrial drives.

- ABB KP4000: A higher-power model (4500 A rating) designed for heavy-duty applications such as mining haulage drives or marine propulsion systems.

- ABB ACS880-04-3000A-3: Frequency converter compatible with the KP3000, optimized for large motors in paper mills and steel plants.

- ABB PM500: Power management module that integrates with the KP3000 for real-time energy monitoring and predictive maintenance.

- ABB TB533: Terminal block kit for the KP3000, simplifying high-current wiring in control cabinets and reducing installation time by 40%.

Pre-installation preparation: Ensure the mounting surface is flat and thermally conductive, applying a thin layer of thermal grease between the module and heat sink to minimize thermal resistance. Verify power supply specifications (220 V DC nominal) and secure connections using torque-controlled screws (10–12 Nm for power terminals). Use shielded cables for control signals to prevent EMI interference, and ground the module chassis to meet safety standards.

Maintenance recommendations: Regularly inspect the module for signs of physical damage or corrosion, particularly in high-humidity environments. Use a thermal imaging camera to monitor junction temperatures, ensuring they remain below 110°C under full load. Replace cooling fans or liquid cooling system filters annually to maintain optimal heat dissipation. ABB’s predictive maintenance software can analyze module health data, alerting operators to potential issues like capacitor degradation or contact wear before they cause downtime.

ABB guarantees the KP3000 to meet performance specifications for 36 months from delivery, backed by rigorous testing for electrical endurance (1 million switching cycles) and environmental stress (salt fog, vibration). The module’s design complies with IEC 60664-1 for voltage withstand and IEC 61800-5-1 for drive systems, ensuring compatibility with global safety standards. ABB’s global service network provides 24/7 technical support, including remote diagnostics and on-site repair by certified technicians. For critical applications, extended warranties and priority spare parts delivery are available, reflecting ABB’s commitment to maximizing system uptime and operational efficiency.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide