Description

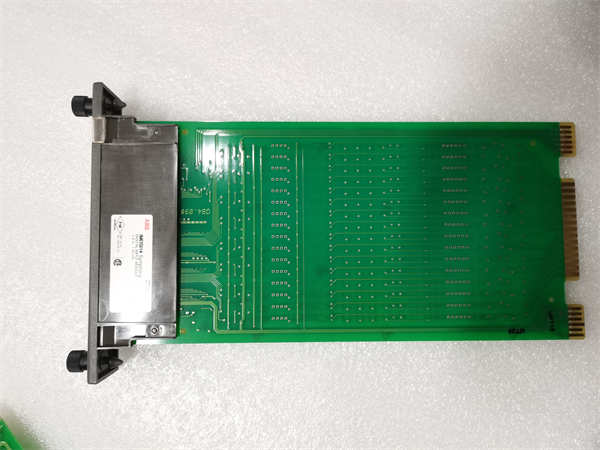

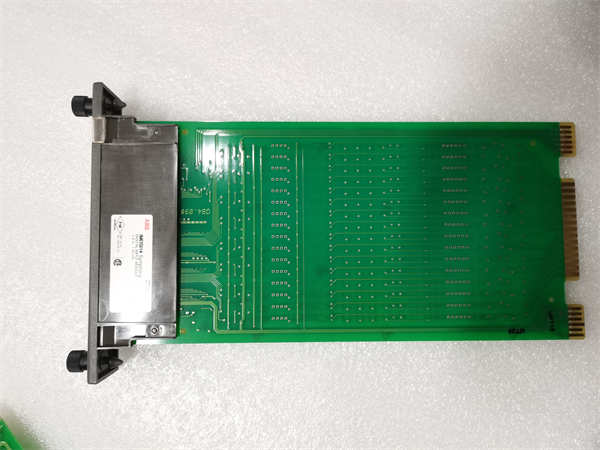

The IMDSI14 is a high-reliability digital input module designed by ABB for industrial automation systems, specifically optimized for Bailey INFI 90 Distributed Control Systems (DCS). As a core component of ABB’s INFI 90 platform, the IMDSI14 provides 16 isolated digital input channels for monitoring discrete signals in complex process environments such as oil and gas, chemical processing, power generation, and water treatment.

The

IMDSI14 serves as a critical interface between field devices (e.g., switches, sensors, and relays) and the INFI 90 DCS, converting analog signals into digital data for real-time processing. With

48 VDC input voltage and

1,500 VDC isolation per channel, it ensures robust signal integrity in harsh industrial conditions. Its modular design supports easy integration with INFI 90 controllers and I/O modules, while LED indicators on the front panel provide real-time status monitoring for efficient troubleshooting.

| Parameter |

Specification |

| Input Voltage |

48 VDC ±10% |

| Input Current |

12 mA per channel |

| Isolation Voltage |

1,500 VDC |

| Signal Type |

Dry contact or DC voltage |

| Filtering Time |

17 ms (slow mode) |

| Response Time |

≤ 20 ms |

| Communication Interface |

INFI 90 I/O bus (via terminal unit) |

| Operating Temperature |

-25°C to +70°C |

| Dimensions |

17.5 mm × 88 mm × 69 mm |

| Weight |

1.5 kg |

IMDSI14

- High Reliability: 1,500 VDC channel isolation protects against voltage surges and electromagnetic interference (EMI), ensuring stable operation in high-noise environments.

- Flexible Configuration: Supports dry contact or DC voltage inputs (48 VDC), adapting to diverse field device requirements.

- Modular Design: Easy replacement and expansion within INFI 90 systems, reducing downtime during maintenance.

- LED Diagnostics: Front-panel indicators provide instant visibility of input status and fault conditions.

- Wide Temperature Range: Operates reliably in extreme environments (-25°C to +70°C), suitable for outdoor or high-temperature applications.

- Oil and Gas: Used in pipeline monitoring systems to detect valve positions and pressure alarms, ensuring safe and efficient operations.

- Chemical Processing: Implemented in batch reactors to monitor start/stop signals and temperature thresholds, improving process consistency.

- Power Generation: Monitors generator breaker status and emergency shutdown signals in thermal power plants.

- Water Treatment: Controls pump activation and level sensors in wastewater treatment facilities.

Case Study: A European chemical plant deployed IMDSI14 modules to monitor 160+ field devices across 10 production lines. The system achieved 99.9% uptime and reduced maintenance costs by 25% through real-time fault detection.

- Isolation Voltage: 1,500 VDC vs. 1,000 VDC in comparable modules, offering superior surge protection.

- Temperature Range: -25°C to +70°C vs. 0°C to +50°C, enabling Arctic and desert deployments.

- Channel Density: 16 channels in a single module vs. 8–12 channels in 竞品,reducing cabinet space by 30%.

- Filtering Time: 17 ms (fixed) vs. 1–100 ms adjustable, optimizing noise immunity for industrial environments.

IMDSI14

- System Compatibility: Pair with INFI 90 controllers (e.g., IMMPC11) for seamless integration; use IMDSI12 for lower voltage inputs (24 VDC).

- Environment: Choose IP65-rated variants for outdoor or washdown areas.

- Redundancy: Implement dual-channel configurations for mission-critical applications (e.g., offshore platforms).

- Budget: Balance channel density (16 channels) with project requirements to minimize hardware costs.

- Wiring: Use shielded cables (AWG 22–18) and M12 connectors to prevent signal interference.

- Grounding: Connect the module’s ground terminal to a dedicated earth ground to avoid ground loops.

- Firmware: Update via ABB’s INFI 90 Composer software to access advanced diagnostics.

- Safety: Disconnect power for 10 minutes post-shutdown before servicing; wear ESD gloves to prevent component damage.

Shanxi Xinyeda International Trading Co., Ltd. supplies

new and refurbished IMDSI14 modules, fully tested for ABB system compatibility. Our

5-year warranty and 24/7 technical support ensure seamless integration. Visit

www.xydcontrol.com or contact us for quotes and retrofitting guidance.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide