Description

The

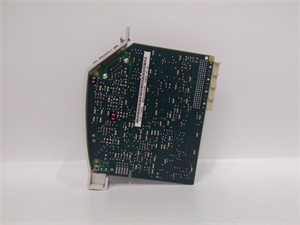

ABB FI830F is a high-performance

fieldbus communication module designed for industrial automation systems, specifically engineered to enhance connectivity and data exchange in complex control environments. As part of ABB’s

AC800M modular controller family, the

FI830F serves as a critical interface between PLC systems, sensors, actuators, and higher-level supervisory networks. Its core function is to enable reliable communication via

PROFIBUS DP V1, supporting real-time data transfer and diagnostic capabilities for mission-critical applications.

The FI830F is optimized for industries such as manufacturing, oil and gas, power generation, and water treatment, where seamless integration and robust communication are essential. It features a compact design (28 mm width) with hot-swap capability, allowing for quick replacement without system downtime. The module supports redundant power supply and fail-safe operation, ensuring continuous performance even in harsh industrial conditions.

| Parameter |

Specification |

| Model Number |

FI830F |

| Brand |

ABB |

| Communication Protocol |

PROFIBUS DP V1, MODBUS TCP (via gateway) |

| Power Supply |

24V DC ±10% |

| Current Consumption |

≤500 mA at full load |

| Operating Temperature |

-40°C to +70°C |

| Storage Temperature |

-45°C to +85°C |

| Mechanical Dimensions |

28 mm (W) x 155 mm (H) x 125 mm (D) |

| Certifications |

CE, RoHS, IEC 61131-2 |

| Compatibility |

ABB AC800M, S800 I/O systems |

| Data Transfer Rate |

Up to 12 Mbps |

| Redundancy Support |

Optional dual-port configuration |

ABB FI830F

- High Reliability: With a mean time between failures (MTBF) exceeding 100,000 hours, the FI830F ensures minimal downtime in critical operations. Its rugged design withstands electromagnetic interference (EMI) and voltage fluctuations, making it suitable for electrically noisy environments.

- Flexible Integration: The module seamlessly integrates with ABB’s AC800M controllers and S800 I/O systems, as well as third-party devices via standard protocols. This flexibility simplifies retrofitting of legacy systems or expansion of new installations.

- Advanced Diagnostics: Built-in diagnostic tools provide real-time status monitoring, error alerts, and detailed fault logs, enabling proactive maintenance and rapid issue resolution.

- Hot-Swap Capability: The module supports live replacement without powering down the system, reducing maintenance time and improving operational efficiency.

- Energy Efficiency: Low power consumption (≤500 mA) and wide voltage tolerance (24V DC ±10%) optimize energy usage in demanding applications.

The FI830F is widely deployed in industries requiring high-speed data exchange and reliable control:

- Manufacturing: 用于生产线自动化、机器人控制和质量监控。

- Oil and Gas: 支持远程设备监控、过程优化和安全联锁系统。

- Power Generation: 管理发电机组、电网稳定性和能源 distribution.

- Water Treatment: 监控水质处理流程、泵组控制和环保系统。

Case Study: A chemical processing plant in Southeast Asia integrated the FI830F to modernize its batch control system. By replacing outdated communication modules, the plant achieved a 20% reduction in downtime due to communication errors and a 15% improvement in process efficiency within three months. The module’s redundancy features also enhanced system resilience during peak production periods.

Compared to similar fieldbus modules, the FI830F distinguishes itself through:

- Superior Protocol Support: Native PROFIBUS DP V1 compatibility eliminates the need for additional gateways, reducing complexity and costs.

- Wide Temperature Range: Operates reliably from -40°C to +70°C, outperforming many competitors in extreme environments.

- ABB Ecosystem Integration: Seamless compatibility with ABB’s 800xA DCS and AC800M controllers ensures optimal performance and simplified maintenance.

- Redundancy Options: Optional dual-port configuration provides failover protection, a feature often absent in mid-tier competitors.

ABB FI830F

When choosing the FI830F:

- System Compatibility: Verify compatibility with your PLC platform (e.g., ABB AC800M) and existing I/O systems.

- Environmental Requirements: Ensure the module’s temperature and EMI resistance match your installation environment, especially for hazardous areas.

- Redundancy Needs: Consider dual-port configuration for mission-critical applications requiring high availability.

- Scalability: Evaluate future expansion needs, as the FI830F supports up to 12 Mbps data transfer for large-scale systems.

- Installation: Power down the system before replacing the module to avoid electrical damage. Use shielded cables to minimize EMI interference.

- Firmware Updates: Regularly update firmware to access the latest security patches and performance optimizations.

- Grounding: Ensure proper grounding and adherence to anti-static procedures to protect internal components.

- Routine Checks: Conduct visual inspections for physical damage or overheating, particularly in high-vibration environments.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide FI830F and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide