Description

Product Description

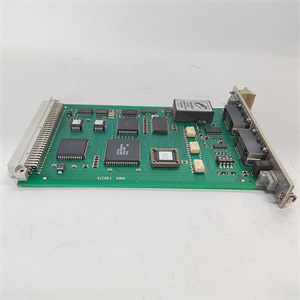

The HIMA F8621A is a high-performance communication module designed for safety-critical industrial automation systems. Engineered by HIMA, a global leader in safety automation solutions, the F8621A serves as a bridge between safety systems and external devices, enabling seamless data exchange and control in industries such as oil & gas, chemical processing, and power generation. Its core function is to provide reliable communication interfaces for connecting HIMA’s H41Q and H51Q safety systems with third-party equipment, including PLCs, SCADA systems, and HMIs.

As a coprocessor module, the F8621A features its own microprocessor (HD 64180, 10 MHz) and 384 KB static memory, allowing it to handle complex communication tasks independently of the main CPU. This design enhances system performance by offloading communication processing, ensuring real-time data transmission even in high-demand environments. The module supports multiple communication protocols, such as RS485 half-duplex with galvanic isolation, making it suitable for environments requiring robust data transmission. It features two independent RS485 ports, allowing simultaneous connections to different networks or devices, and its dual-port RAM enables fast memory access to the central module, optimizing data exchange efficiency.

Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24 VDC (±10%) |

| Current Consumption | Max. 1 A |

| Communication Interfaces | 2 x RS485 (half-duplex, galvanically isolated), supports baud rates up to 57.6 kbps |

| Compatibility | HIMA H41Q/H51Q safety systems, third-party PLCs, SCADA, and HMIs |

| Safety Integrity Level | SIL 3 (IEC 61508) |

| Operating Temperature | -20°C to +60°C |

| Dimensions | 120 x 76 x 60 mm |

| Weight | 1.5 kg |

| Certifications | CE, UL, CSA, IEC 61508, EN 50128 |

| Processor | HD 64180, 10 MHz |

| Memory | 384 KB static memory |

| Dual-Port RAM | Supports fast memory access to the central module |

HIMA F8621A

Advantages and Features

-

High Safety Integrity:

The F8621A is certified to SIL 3, ensuring compliance with the highest safety standards for critical applications. Its fail-safe design guarantees reliable operation even in the event of hardware or software failures, making it a trusted choice for environments where system downtime could lead to severe consequences. -

Flexible Communication:

With support for RS485 and multiple baud rates, the module adapts to diverse industrial networks. Its galvanic isolation protects against ground loops and voltage spikes, enhancing system stability and reducing the risk of data corruption in noisy environments. -

Modular Design:

The F8621A integrates seamlessly into HIMA’s modular safety systems, allowing easy expansion and customization. It can be hot-swapped without disrupting operations, minimizing downtime during maintenance and ensuring continuous system availability. -

Energy Efficiency:

Consuming less than 5 W, the module reduces power costs while maintaining high performance. Its low-power design is ideal for energy-sensitive applications, contributing to long-term operational savings. -

Robust Construction:

Built with industrial-grade materials, the F8621A resists dust, moisture, and extreme temperatures, ensuring long-term reliability in harsh industrial environments such as offshore platforms or chemical plants. -

Coprocessor Architecture:

The dedicated microprocessor and dual-port RAM enable efficient handling of communication tasks, reducing the load on the main CPU and improving overall system responsiveness, even when managing multiple simultaneous data streams.

Application Areas and Application Cases

Industry Applications:

- Oil & Gas: Used in offshore platforms and refineries to connect safety systems with emergency shutdown (ESD) valves, fire detection systems, and process control networks, ensuring rapid response to critical events.

- Chemical Processing: Integrates with batch reactors, distillation units, and storage systems to monitor and control hazardous processes, preventing leaks, overpressure, or temperature anomalies.

- Power Generation: Manages safety-critical functions in power plants, such as turbine protection, boiler control, and generator monitoring, to maintain grid stability and prevent equipment damage.

Case Study:

In a large-scale petrochemical plant, the HIMA F8621A was deployed to connect HIMA’s H51Q safety system with a third-party SCADA system. The module enabled real-time monitoring of pressure and temperature sensors in distillation towers. When a sudden pressure surge was detected, the F8621A transmitted an immediate shutdown signal to the safety system, preventing a potential overpressure incident that could have caused equipment failure and environmental harm. This integration reduced unplanned downtime by 30% and enhanced the plant’s safety profile.

In a large-scale petrochemical plant, the HIMA F8621A was deployed to connect HIMA’s H51Q safety system with a third-party SCADA system. The module enabled real-time monitoring of pressure and temperature sensors in distillation towers. When a sudden pressure surge was detected, the F8621A transmitted an immediate shutdown signal to the safety system, preventing a potential overpressure incident that could have caused equipment failure and environmental harm. This integration reduced unplanned downtime by 30% and enhanced the plant’s safety profile.

Competitor Comparison

The F8621A stands out in the market due to its combination of SIL 3 certification and galvanic isolation, which are often not matched by similar modules that typically offer only SIL 2 compliance. Unlike many alternatives, it provides a robust fail-safe design and seamless compatibility with HIMA’s advanced safety systems, ensuring optimal performance in complex industrial setups. Its hot-swap capability and modular architecture also offer superior ease of maintenance and scalability compared to non-modular competitors, making it a preferred choice for mission-critical applications.

HIMA F8621A

Selection Suggestions

- Compatibility: Verify that the module works with your existing safety system (e.g., H41Q/H51Q) and third-party devices, ensuring protocol and hardware compatibility.

- Environmental Requirements: Assess the operating temperature, humidity, and electromagnetic interference (EMI) levels in your facility to ensure the F8621A can operate reliably without additional protective measures.

- Communication Needs: Confirm support for RS485 and the required baud rates to match your network infrastructure, especially if integrating with legacy systems.

- Budget Considerations: Balance the upfront cost with long-term benefits, such as reduced downtime, energy savings, and compliance with strict safety standards.

Precautions

-

Installation:

- Follow HIMA’s technical guidelines for proper grounding and cable routing to minimize EMI interference and ensure stable communication.

- Install the module in a protected enclosure if operating in environments with high dust, moisture, or vibration.

-

Maintenance:

- Regularly update the module’s firmware using HIMA’s approved tools to ensure compatibility with the latest safety protocols and software updates.

- Inspect connections and perform visual checks quarterly to identify loose cables or signs of wear, especially in harsh environments.

-

Troubleshooting:

-

Use HIMA’s diagnostic software to monitor communication errors, voltage levels, and module health.

-

In case of persistent issues, consult the user manual or contact authorized technical support for assistance, avoiding unauthorized modifications to the module.

-

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide HIMA F8621A and other automation spare parts, along with sales and technical support. Visit our website www.xydcontrol.com or contact us for more information.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide