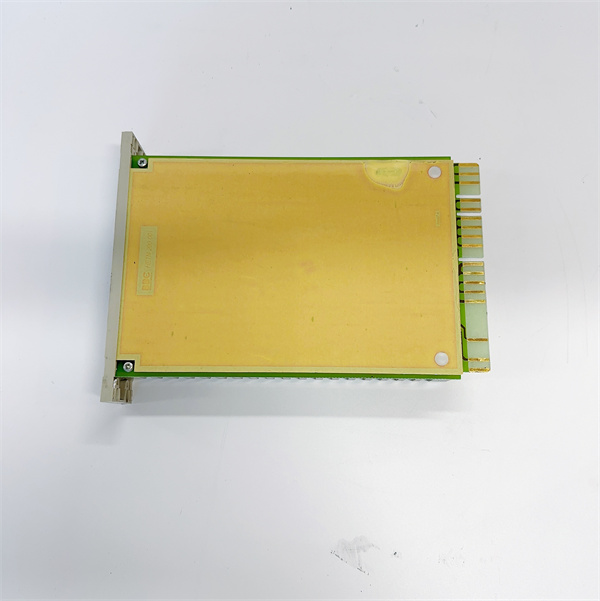

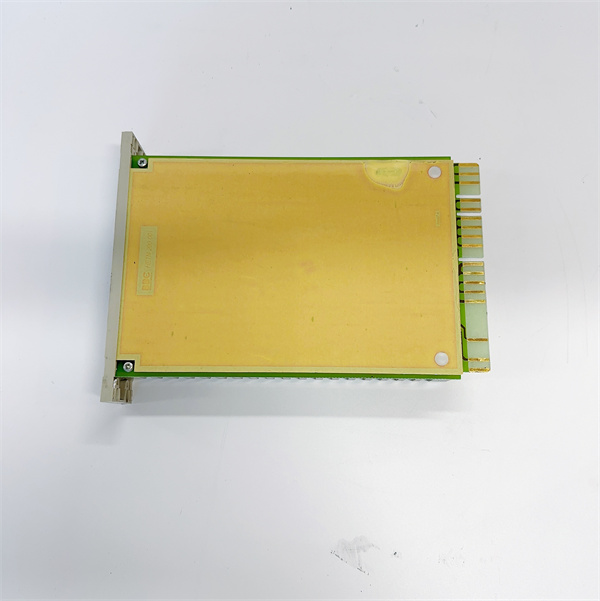

Description

ABB E3ES is a high-performance air circuit breaker (ACB) belonging to ABB’s Emax 2 series, designed for medium and low-voltage power distribution systems. Engineered to deliver reliable power control and protection,

E3ES is ideal for applications requiring precise management of electrical loads, such as in industrial plants, data centers, commercial buildings, and energy infrastructure. This 抽出式 (withdrawable) circuit breaker features advanced electronic trip units and communication capabilities, enabling real-time monitoring, fault protection, and remote control.

ABB E3ES ensures system safety, efficiency, and scalability by combining robust mechanical design with intelligent automation features.

| Parameter |

Specification |

| Voltage Rating |

AC 400 V / 690 V (50/60 Hz) |

| Current Rating |

1600 A – 3200 A (variable by model) |

| Short-Circuit Breaking Capacity (Icu) |

85 kA (400 V) / 50 kA (690 V) |

| Short-Time Withstand Current (Icw) |

65 kA/1s (400 V) |

| Trip Unit Type |

Electronic (E3.2ES/E3.3ES with Modbus/Profibus support) |

| Communication |

Built-in RS-485, Ethernet/IP (optional) |

| Mounting Style |

Withdrawable (3-position: connected/test/isolate) |

| Protection Functions |

Overload, short circuit, earth fault, undervoltage |

| Operating Temperature |

-25°C to +60°C |

| Mechanical Life |

Up to 40,000 operations |

ABB E3ES

- Intelligent Protection: ABB E3ES incorporates advanced electronic trip units that enable precise adjustment of protection parameters (e.g., overload delay, short-circuit threshold). In a manufacturing plant case study, its rapid fault detection (≤10 ms response time) reduced equipment damage by 40%.

- Digital Connectivity: With built-in communication protocols, E3ES integrates seamlessly with supervisory control and data acquisition (SCADA) systems, allowing remote monitoring of power parameters (voltage, current, energy consumption) and remote switching. This feature reduced maintenance costs by 25% in a data center application.

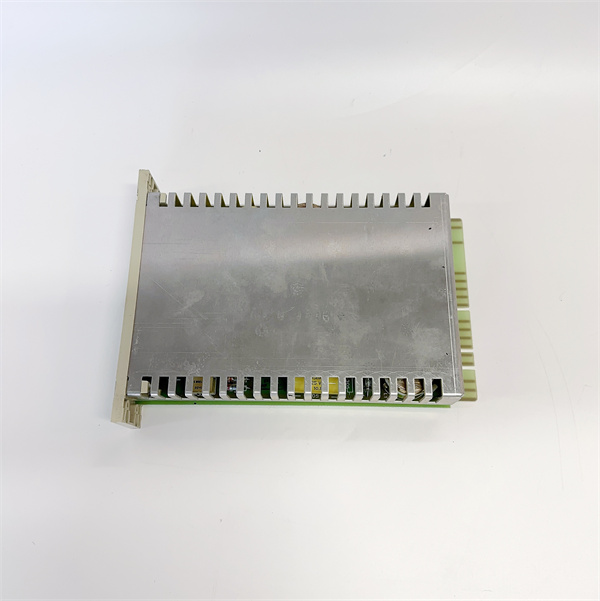

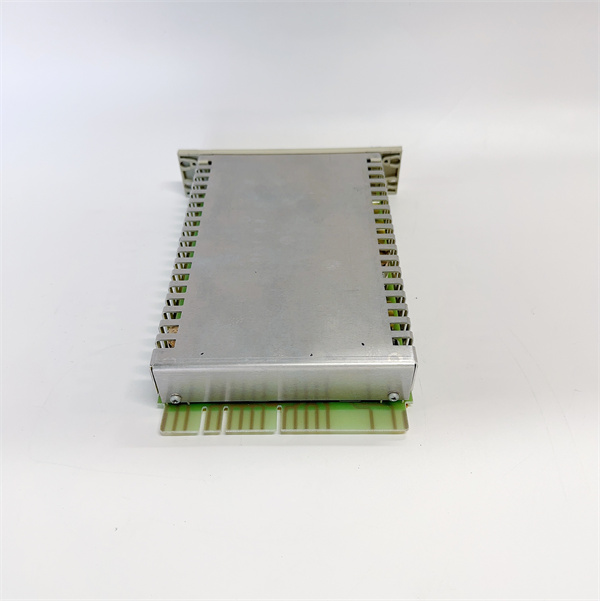

- Rugged Design: The withdrawable design ensures safe maintenance without powering down the entire system, while the IP54 protection rating (when mounted in a cabinet) makes it suitable for dusty or humid environments. Its mechanical life of 40,000 cycles exceeds industry standards for reliability.

- Space-Saving: The compact frame design saves up to 30% space in switchgear compared to older-generation circuit breakers, optimizing cabinet layout in dense installations.

Industry Applications:

- Industrial Automation: Main power distribution in factories, motor control centers (MCCs), and process control systems.

- Data Centers: Redundant power systems for uninterruptible power supply (UPS) networks, ensuring continuous operation.

- Commercial Buildings: Low-voltage switchgear in office complexes, hospitals, and shopping centers for reliable power management.

- Renewable Energy: Integration with solar/wind farms for grid-connected power distribution.

Case Study: A large pharmaceutical facility deployed ABB E3ES in its production line’s main switchboard. The breaker’s real-time energy monitoring and remote control capabilities helped optimize power usage, reducing energy costs by 18%. Its quick fault isolation feature also minimized downtime during maintenance, improving production efficiency by 12%.

Compared to similar air circuit breakers, ABB E3ES stands out for its superior communication flexibility and scalability. While some competitors offer basic protection functions, E3ES’s support for multiple industrial protocols (Modbus, Profibus) and optional Ethernet/IP connectivity makes it more adaptable to modern smart grids. Its robust mechanical design and higher short-circuit breaking capacity (85 kA at 400 V) also provide a competitive edge in high-demand industrial environments.

ABB E3ES

- Current and Voltage Requirements: Choose a model with a current rating 20% higher than the maximum load to avoid overheating, and ensure voltage compatibility with your system (400 V or 690 V).

- Communication Needs: Opt for the E3.3ES variant if integrating with a digital control system to leverage advanced monitoring features.

- Environmental Conditions: In harsh environments (e.g., high humidity, dust), ensure the breaker is installed in a properly sealed cabinet to maintain IP54 protection.

- Scalability: Consider future load expansions by selecting a frame size that allows for higher current ratings without replacing the entire breaker.

- Installation: Ensure proper grounding and follow ABB’s guidelines for cable sizing and torque specifications to prevent loose connections.

- Maintenance: Regularly inspect the breaker for signs of wear (e.g., burnt contacts) and test the trip unit functionality annually. Clean dust from the housing to maintain thermal performance.

- Safety Protocol: Always switch the breaker to the “isolate” position and verify no voltage before performing maintenance to avoid electric shock.

- Firmware Updates: Periodically update the trip unit firmware via ABB’s dedicated software to ensure compatibility with new features and security patches.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide