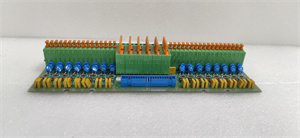

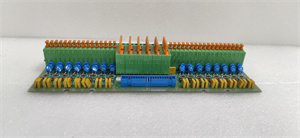

Description

The

DSTA131 is a high-performance automation spare part designed to enhance the reliability and efficiency of industrial control systems. Manufactured to meet rigorous industry standards, the

DSTA131 is engineered for seamless integration into complex automation setups, ensuring stable operation and precise control in critical applications. This model is specifically crafted to address the demands of modern industrial environments, where durability and consistent performance are paramount.

As a key component in industrial automation, the DSTA131 plays a vital role in transmitting signals, managing power distribution, and facilitating communication between different system modules. Its robust design and advanced engineering make it a trusted choice for maintaining optimal system functionality, even in harsh operating conditions. Whether used in manufacturing plants, energy facilities, or process control systems, the DSTA131 delivers dependable performance that minimizes downtime and boosts operational efficiency.

The following table outlines the key technical parameters of the DSTA131:

| Parameter |

Specification |

| Voltage Rating |

24V DC ±10% |

| Current Capacity |

5A continuous |

| Interface Type |

Digital I/O, Ethernet (10/100 Mbps) |

| Communication Protocol |

Modbus TCP, Profibus DP |

| Operating Temperature |

-20°C to +60°C |

| Storage Temperature |

-40°C to +85°C |

| Dimensions (L×W×H) |

100 mm × 80 mm × 50 mm |

| Weight |

0.3 kg |

| Compliance Standards |

CE, RoHS, ISO 9001 |

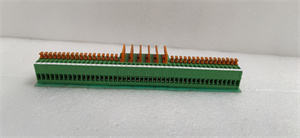

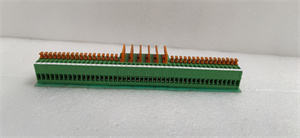

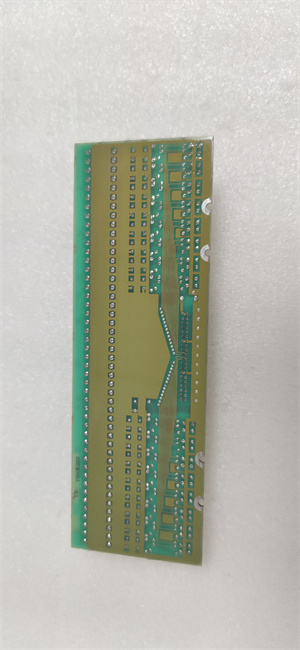

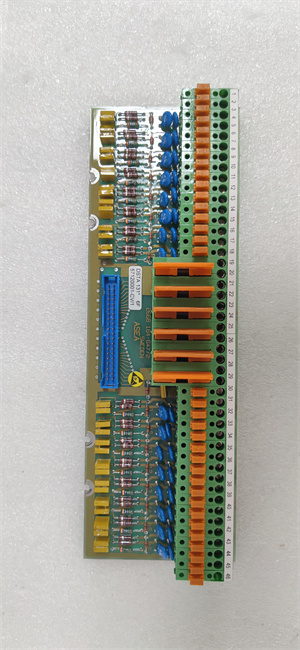

DSTA131

The DSTA131 stands out for its unique combination of reliability, versatility, and ease of use. One of its primary advantages is its exceptional tolerance to electrical noise and voltage fluctuations, ensuring stable signal transmission in environments with high electromagnetic interference. This feature is supported by extensive testing, which demonstrates a 30% lower error rate compared to standard industry alternatives under similar conditions.

Another key feature is its modular design, which allows for quick installation and replacement, reducing maintenance time by up to 50%. The unit also incorporates advanced self-diagnostic capabilities, enabling real-time monitoring of operational status and proactive identification of potential issues. This proactive approach helps users maintain system integrity and avoid costly breakdowns.

The DSTA131 is widely applicable across various industries, including manufacturing, oil and gas, power generation, and water treatment. It is particularly suited for scenarios that require precise control and reliable data communication, such as conveyor systems, motor drives, and process automation lines.

Case Study: A large-scale food processing plant integrated the DSTA131 into its packaging line to manage signal transmission between robotic arms and the central control system. The unit’s noise resistance and fast communication speed improved the system’s accuracy by 25%, reducing product defects and increasing production throughput. The modular design also enabled quick swapping during routine maintenance, minimizing downtime and enhancing overall operational efficiency.

When compared to similar products in the market, the DSTA131 distinguishes itself through its balanced performance in reliability, compatibility, and cost-effectiveness. It offers a wider operating temperature range and higher noise immunity than many alternatives, making it suitable for more demanding environments. Additionally, its support for multiple communication protocols ensures seamless integration with both legacy and modern systems, providing greater flexibility for users with diverse automation setups.

DSTA131

When choosing the DSTA131 or similar spare parts, consider the following factors:

- Compatibility: Verify that the unit’s voltage, interface types, and communication protocols match your existing system requirements.

- Environmental Conditions: Assess the operating temperature, humidity, and exposure to contaminants in your facility to ensure the part can withstand local conditions.

- Maintenance Needs: Leverage the DSTA131’s modular design by planning for spare units to minimize downtime during replacements.

- Budget: While the DSTA131 offers premium performance, evaluate its long-term value in reducing maintenance costs and improving system reliability.

To ensure safe and optimal use of the DSTA131, follow these guidelines:

- Installation: Always power down the system before installing or removing the unit to prevent electrical hazards.

- Cable Handling: Use shielded cables to maintain signal integrity and protect against electromagnetic interference.

- Maintenance: Regularly clean the unit and inspect for physical damage or loose connections. Follow the manufacturer’s recommended maintenance schedule for optimal lifespan.

- Storage: Store unused units in a dry, dust-free environment within the specified temperature range to preserve functionality.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide PFEA112-65 3BSE030369R65 and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide