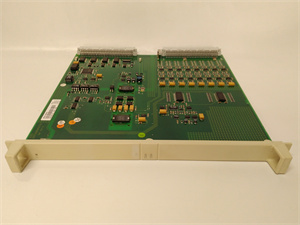

Description

The

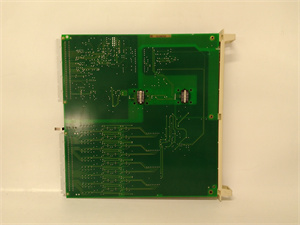

ABB DSAI133A 3BSE018290R1 is a high-precision

analog input module designed for ABB’s

AC 800M distributed control system (DCS), serving as a critical interface for acquiring and conditioning analog signals from field sensors in industrial automation environments. As part of the

DSAI (Distributed Standard Analog Input) series, this module is engineered to convert analog signals from temperature, pressure, and flow sensors into digital data for real-time process control and monitoring. The

DSAI133A 3BSE018290R1 features 8 isolated channels, each supporting multiple signal types (4-20 mA, 0-10 V, thermocouples, RTDs), making it versatile for diverse applications in manufacturing, energy, and process industries.

Equipped with 24-bit analog-to-digital conversion and built-in signal conditioning, the ABB DSAI133A 3BSE018290R1 ensures measurement accuracy within ±0.1% of full scale, even in high-noise environments. Its galvanic isolation (500 V AC) per channel protects the control system from voltage spikes and ground loops, while the hot-swappable design allows maintenance without disrupting operations. Positioned as a reliable and flexible solution, the module integrates seamlessly with ABB’s 800xA software platform, enabling engineers to configure signal scaling, filter settings, and diagnostic thresholds through a unified interface. By optimizing data integrity and reducing hardware complexity, the DSAI133A 3BSE018290R1 enhances system reliability and operational efficiency in mission-critical applications.

| Parameter Name |

Parameter Value |

| Product Model |

DSAI133A 3BSE018290R1 |

| Manufacturer |

ABB |

| Product Type |

Analog Input Module (8-channel, isolated) |

| Signal Types |

4-20 mA, 0-10 V, ±10 V, thermocouples (J/K/T/E), RTDs (2/3/4-wire) |

| Resolution |

24-bit + sign |

| Accuracy |

±0.1% F.S. (25°C), ±0.2% F.S. (-40°C to +85°C) |

| Channel Isolation |

500 V AC (channel-to-channel/channel-to-system) |

| Sampling Rate |

200 ms/channel (default), configurable |

| Power Supply |

24 V DC (18–30 V DC) from I/O bus |

| Operating Temperature |

-40°C to +85°C |

| Dimensions (W×H×D) |

36 mm × 100 mm × 110 mm |

| Mounting Method |

DIN rail (AC 800M I/O rack) |

| Certification |

CE, UL, IEC 61131-2, IEC 62443-4-1, RoHS |

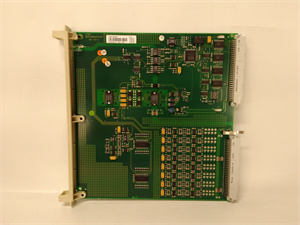

DSAI133A 3BSE018290R1

The DSAI133A 3BSE018290R1 eliminates the need for dedicated signal conditioners by supporting a wide range of sensor types. For example, in a chemical plant, the same module can acquire 4-20 mA signals from pressure transmitters, 0-10 V signals from flow meters, and thermocouple signals from reactor temperature sensors, reducing inventory complexity by 50%. The software-selectable signal types via ABB’s Control Builder M software enable quick reconfiguration for the changing process requirements, such as adapting to a new sensor during a production line upgrade.

The module’s dual-layer isolation (analog frontend + digital backend) and EMC shielding comply with IEC 61000-6-2 standards, making it suitable for harsh environments like steel mills or mining sites, where electromagnetic interference from heavy machinery is prevalent. In a paper mill’s drying section, the DSAI133A 3BSE018290R1 accurately measures steam pressure signals despite high-frequency noise from induction motors, ensuring stable control of the drying process with ±0.5°C temperature precision.

Built-in self-diagnostic functions monitor channel health, including open/short circuit detection and sensor drift alerts, reducing mean time to detect (MTTD) faults by 60%. The module’s modular design allows seamless integration with ABB’s S800 I/O system, supporting up to 128 analog input channels per controller, ideal for large-scale applications like oil refinery 集散控制系统 (DCS). For redundancy, the module can be paired with a DSAI133A in a dual configuration, ensuring continuous operation in critical processes like LNG liquefaction.

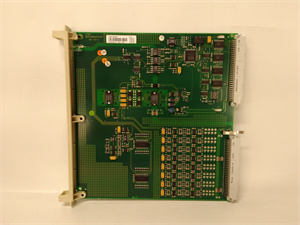

The ABB DSAI133A 3BSE018290R1 is essential in industries requiring precise analog data acquisition:

- Power Generation: Measures boiler temperatures (via K-type thermocouples) and turbine vibration (4-20 mA accelerometers) in thermal power plants, enabling predictive maintenance and compliance with emission standards.

- Food and Beverage: Monitors pasteurization temperatures (RTD sensors) and filling pressures (0-10 V transducers) in dairy production lines, ensuring product safety and consistency with ±0.1°C accuracy.

- Pharmaceuticals: Acquires sterile process parameters (e.g., pH, conductivity) in bioreactors using isolated 4-20 mA signals, meeting FDA 21 CFR Part 11 requirements for data integrity.

- Water Treatment: Measures chlorine levels (analog transmitters) and flow rates in distribution networks, optimizing chemical dosing and reducing non-revenue water losses by 15%.

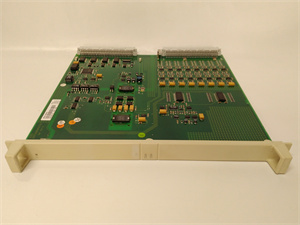

DSAI133A 3BSE018290R1

- ABB DSAI130 3BSE018287R1: A 16-channel variant with lower resolution (16-bit), suitable for basic monitoring applications in small-scale systems.

- ABB DSAI135 3BSE018292R1: A high-speed analog input module (50 ms/channel) for fast-response processes like robotics or high-frequency data logging.

- ABB DSPC170 3BSE066436R1: A processor module for the AC 800M system, which processes data from the DSAI133A and executes control logic.

- ABB TB521: A shielded terminal block for secure wiring of analog signals, reducing noise pickup in high-vibration environments.

- ABB CI524 3BSE018167R1: A Profibus DP interface module, enabling the DSAI133A to communicate with legacy fieldbus devices in hybrid automation systems.

Pre-installation preparation: Mount the DSAI133A 3BSE018290R1 in an AC 800M I/O rack, ensuring proper grounding and separation from high-voltage cables. Use shielded twisted-pair wiring for analog signals, terminating them with ABB’s TB521 terminal blocks. Configure signal types and scaling in Control Builder M, then download the project to the controller. For thermocouple inputs, ensure proper cold junction compensation is enabled in the software.

Maintenance recommendations: Perform quarterly inspections of terminal connections for signs of corrosion or looseness, tightening them to 2.5 N·m torque if necessary. Use ABB’s 800xA Diagnostics tool monthly to review channel accuracy and diagnostic status, recalibrating sensors if deviations exceed ±0.5% F.S. In dusty environments, clean the module’s ventilation slots every six months with compressed air to prevent thermal derating. Annually, update firmware to the latest version to access new features and security patches.

ABB stands behind the DSAI133A 3BSE018290R1 with a 5-year warranty, covering hardware defects, firmware errors, and manufacturing issues. ABB’s global technical support team provides 24/7 remote diagnostics and on-site assistance, with average response times under 4 hours for critical issues. The module undergoes rigorous testing, including 10,000-hour burn-in tests and EMC compliance checks, to ensure adherence to ISO 9001 standards. For customers in regulated industries, ABB offers functional safety assessment services to validate the module’s suitability for SIL 2 applications, such as emergency shutdown systems in petrochemical plants. By combining precision, versatility, and ABB’s industry-leading support, the DSAI133A 3BSE018290R1 sets the standard for analog input modules in modern industrial automation.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide