Description

The

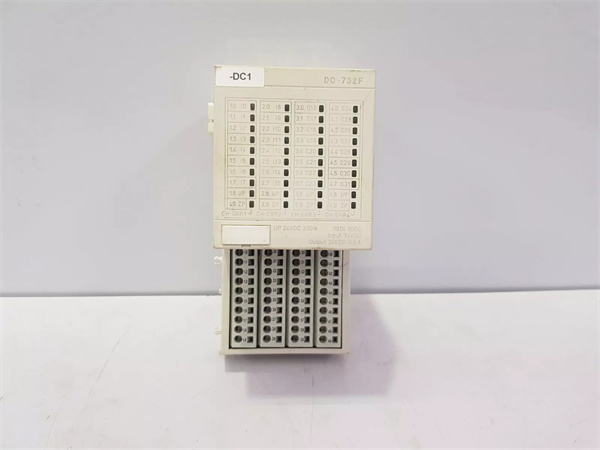

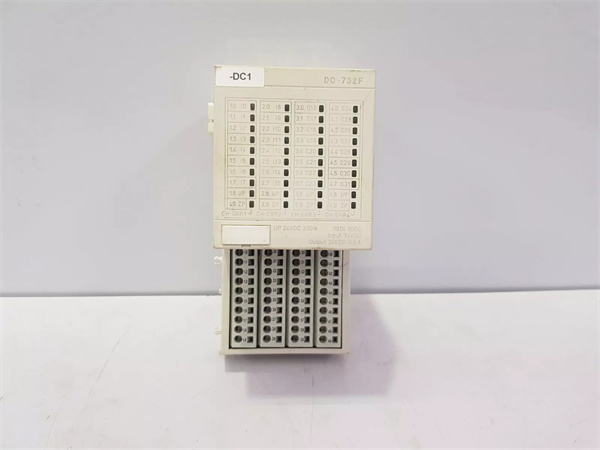

ABB DC732F 3BDH000375R0001 is a high-performance DC drive controller designed for industrial motor control systems, offering precise speed regulation, torque control, and system protection. Engineered for reliability and efficiency, the

DC732F supports dual-loop (speed/torque) control, digital/analog I/O (6DI/4DO/2AI), and communication protocols like Modbus RTU and Profibus-DP. Ideal for applications requiring dynamic response (0–5000 RPM), it ensures ±0.1% speed accuracy and 98% energy efficiency. Its compact design (190x210x150 mm) and rugged construction (IP20/IP54 options) make it suitable for harsh environments, combining advanced functionality with ease of integration.

| Parameter |

Specification |

| Model |

DC732F 3BDH000375R0001 (ABB) |

| Input Voltage |

380–500V AC (3-phase), ±10% |

| Output Current |

75A continuous (150% overload for 60s) |

| Control Method |

Vector control (FOC), armature voltage control |

| I/O Configuration |

6 DI (24V DC), 4 DO (relay), 2 AI (0–10V/0–20mA) |

| Communication Protocols |

Modbus RTU, Profibus-DP (optional) |

| Speed Range |

0–5000 RPM (with encoder feedback) |

| Protection Features |

Overload, overvoltage, short-circuit, thermal |

| Operating Temperature |

-10°C to +50°C (operation), -25°C to +70°C (storage) |

| Weight |

5.2 kg |

DC732F 3BDH000375R0001

- Precision Control: Vector control technology achieves ±0.1% speed accuracy (vs. ±0.5% in standard drives) and 50:1 speed regulation ratio.

- Energy Efficiency: Regenerative braking capability reduces energy consumption by 30% in reversing applications.

- Rugged Design: IP54-rated enclosure (optional) resists dust and moisture, with conformal coating for corrosion protection.

- Advanced Diagnostics: Real-time monitoring of motor parameters (current, temperature), fault logging (50 events), and remote troubleshooting via PC tools.

- Flexible Integration: DIN-rail or panel mounting, with expandable I/O modules (up to 16 DI/10 DO).

Industries: Manufacturing (conveyor systems, pumps), metal processing, water/wastewater treatment, and material handling.

典型场景: High-torque applications (e.g., crane drives, extruders) and variable-speed motor control (up to 45kW).

案例: A steel mill in India integrated the DC732F for its rolling mill drives. The controller’s vector control reduced torque ripple by 40%, improving product quality and extending motor lifespan by 20%. Downtime decreased by 15% due to predictive maintenance features.

Compared to similar DC drives:

- Faster Dynamic Response: 5ms current loop update (vs. 10–15ms in legacy models).

- Higher Power Density: 75A in 190mm width (vs. 60A in same size from competitors).

- Built-in Safety: STO (Safe Torque Off) SIL3 compliance (optional), reducing external safety component costs.

- Software Tools: ABB’s Drive composer Pro offers advanced tuning (FFT analysis, oscilloscope) at no extra cost.

DC732F 3BDH000375R0001

- Compatibility: Match motor type (shunt, series, permanent magnet) and voltage class (380–500V).

- Environment: Choose IP54 for dusty/humid sites; IP20 for controlled environments.

- Performance Needs: Opt for vector control (with encoder) for high-precision applications; armature control for basic speed regulation.

- Scalability: Add I/O modules (e.g., TC532 for temperature sensors) for complex systems.

- Installation: Follow cable sizing guidelines (≥6mm² for power cables) and separate power/control cabling to prevent EMI.

- Commissioning: Calibrate motor parameters (armature resistance, field current) using ABB’s commissioning wizard.

- Maintenance: Clean cooling vents quarterly; replace capacitors every 5–7 years (depending on duty cycle).

- Safety: Disconnect power for 10 minutes before servicing. Use ESD protection for circuit boards.

山西鑫业达国际贸易有限公司 (Shanxi Xinyeda International Trade Co., Ltd.) is your trusted partner for

ABB DC732F 3BDH000375R0001 and automation spare parts. We offer sales, technical support, and repair services. Visit

www.xydcontrol.com or contact us for customized solutions.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide