Description

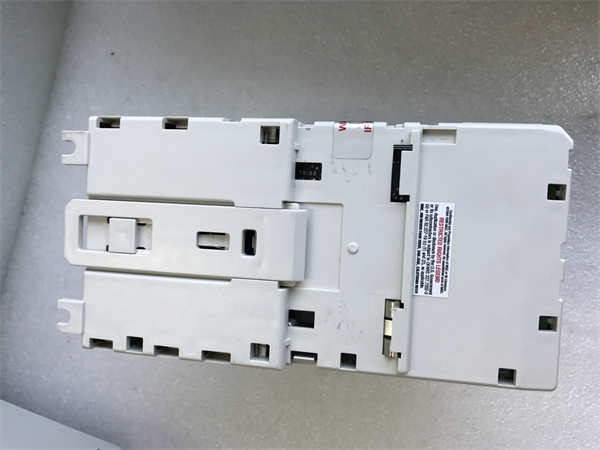

The CI810B is a robust and versatile communication interface module developed by ABB, a global leader in industrial automation solutions. Designed to enhance connectivity in complex control systems, the CI810B enables seamless data exchange between programmable logic controllers (PLCs) and a wide range of field devices, making it an essential component for modern industrial automation environments.

The

CI810B is engineered to facilitate reliable communication in demanding industrial settings, supporting multiple protocols to connect PLCs with sensors, actuators, and intelligent devices. This module ensures stable, high-speed data transmission even in harsh conditions, catering to applications that require real-time control and monitoring. Its compact design and user-friendly configuration simplify integration into existing systems, while advanced diagnostic features help maintain operational efficiency by enabling quick fault detection and resolution.

| Parameter |

Specification |

| Brand |

ABB |

| Model |

CI810B |

| Type |

Communication Interface Module |

| Voltage Supply |

24V DC ±10% |

| Power Consumption |

Low-power design, typical <5W |

| Communication Protocols |

PROFIBUS DP, Modbus RTU, Ethernet/IP |

| Interface Types |

RS-485, Ethernet (10/100 Mbps) |

| Compatibility |

ABB AC 800M, PLCnext Technology, and third-party systems supporting standard protocols |

| Operating Temperature |

-20°C to +60°C |

| Protection Rating |

IP20 (suitable for indoor industrial use) |

| Dimensions (W×H×D) |

Compact form factor for space-constrained setups |

ABB CI810B

- Multi-Protocol Connectivity: The CI810B supports multiple industrial communication protocols, allowing it to integrate seamlessly with both legacy and modern devices without requiring additional hardware, reducing system complexity and costs.

- Rugged Industrial Design: Built with durable components, the module withstands electrical noise, voltage fluctuations, and extreme temperatures, ensuring consistent performance in challenging environments such as manufacturing plants or energy facilities.

- Real-Time Data Performance: Enables low-latency data transfer over Ethernet at speeds up to 100 Mbps, critical for applications that demand instant feedback, such as robotic control or process optimization.

- Simplified Commissioning: User-friendly configuration tools streamline setup and parameter adjustment, minimizing installation time and reducing the risk of operational errors.

- Proactive Maintenance Support: Built-in diagnostic functions and status indicators provide real-time insights into module health, facilitating predictive maintenance and minimizing downtime.

- Manufacturing Automation: Integrates PLCs with assembly line equipment, robotic arms, and quality control systems to ensure synchronized production processes.

- Energy and Utilities: Used in power generation and distribution to connect control systems with sensors, meters, and SCADA networks for real-time monitoring and grid management.

- Process Industries: Links PLCs with valves, pumps, and analytical instruments in chemical, oil, and gas plants to enable precise process control and safety monitoring.

A leading automotive manufacturer deployed the CI810B to connect its ABB PLCs with a network of conveyor belts, welding robots, and vision inspection systems in a new assembly line. The module’s multi-protocol support allowed seamless communication between different device brands, improving production line efficiency by 20% and reducing integration time by 25%. Its robust design ensured uninterrupted operation even in the high-vibration environment of the factory floor.

Compared to similar interface modules, the CI810B stands out for its combination of protocol versatility, reliability, and ease of integration. While some alternatives may prioritize single-protocol performance or basic connectivity, the CI810B offers a comprehensive solution that adapts to evolving industrial requirements. Its compliance with international standards and proven track record in harsh environments make it a preferred choice for mission-critical applications where downtime is not an option.

ABB CI810B

- Protocol Matching: Ensure your existing control system or planned devices support the protocols offered by the CI810B (e.g., PROFIBUS DP, Modbus RTU, Ethernet/IP) to guarantee compatibility.

- Environmental Fitness: Evaluate the operating temperature, humidity, and exposure to contaminants in your facility to confirm the module’s IP20 rating and temperature range suit your needs.

- Scalability Planning: If your system is likely to expand, choose the CI810B for its ability to handle increased data loads and support future device additions without major reconfiguration.

- Cost-Benefit Analysis: Balance the module’s advanced features, such as rugged construction and multi-protocol support, against your project’s budget to ensure optimal value for performance-critical applications.

- Installation Best Practices: Follow ABB’s guidelines for proper grounding and cable shielding to minimize electromagnetic interference (EMI) and ensure stable signal transmission. Securely fasten connectors to prevent loose connections during operation.

- Software Configuration: Use only ABB-approved software tools for firmware updates and parameter settings to avoid compatibility issues. Always back up configuration files before making changes to simplify recovery in case of errors.

- Routine Maintenance: Regularly inspect the module for physical damage, loose wires, or dust accumulation, especially in high-dust environments. Clean vents gently to maintain proper heat dissipation and prevent overheating.

- Safety Compliance: Always power down the system and disconnect the power supply before installing or servicing the CI810B to prevent electrical hazards or accidental device damage.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide PFEA112-65 3BSE030369R65 and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide