Description

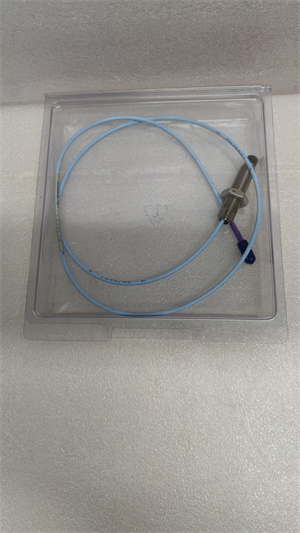

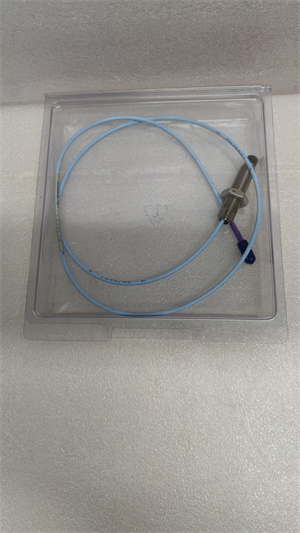

The BENTLEY 330703-000-060-10-02-00 is a high-precision eddy current proximity probe designed for non-contact measurement of shaft displacement, vibration, and axial position in rotating machinery. As part of Bentley’s 3300 XL Series, this sensor system combines advanced engineering with rugged durability, making it ideal for critical applications in industries such as oil & gas, power generation, and manufacturing.

The

BENTLEY 330703-000-060-10-02-00 is an

11 mm proximity probe that converts mechanical movements into electrical signals, enabling real-time monitoring of rotating equipment health. Its core features include:

- Non-Contact Measurement: Uses eddy current technology to detect shaft displacement (0–8 mm range) without physical contact, eliminating wear and tear on machinery components.

- High-Frequency Response: Captures dynamic movements up to 8 kHz, ensuring accurate detection of vibration and imbalance issues in high-speed turbines and compressors.

- Extreme Environment Resilience: Operates at temperatures ranging from -51°C to +177°C (-60°F to +351°F), with cable ratings up to +260°C (+500°F) for high-heat applications like gas turbines.

- Flexible Integration: Designed for compatibility with Bentley’s 3500 Monitoring System and third-party PLC/DCS platforms, supporting standardized -20 to 0 VDC output signals.

The 330703-000-060-10-02-00 is engineered for complete interchangeability, allowing seamless replacement of probes, extension cables, and sensors without recalibration. This reduces downtime and maintenance costs in mission-critical environments.

| Parameter |

Specification |

| Brand |

BENTLEY |

| Model |

330703-000-060-10-02-00 |

| Sensor Type |

Eddy current proximity sensor (11 mm probe) |

| Measurement Range |

0–8 mm (0–315 mil) |

| Sensitivity |

7.87 mV/μm (200 mV/mil) |

| Linearity Error |

<1% of full scale |

| Frequency Response |

0–8 kHz (±3 dB) |

| Operating Temperature |

-51°C to +177°C (-60°F to +351°F) |

| Supply Voltage |

-17.5 to -26 VDC (nominal -24 VDC) |

| Output Signal |

-20 to 0 VDC (proportional to displacement) |

| Cable Configuration |

1-meter system length with miniature coaxial Click Loc connector |

| Compatibility |

Bentley 3500 Series, PLC/DCS systems |

| Certifications |

API 670 compliant (4th edition) |

BENTLY 330703-000-060-10-02-00

- Exceptional Accuracy: With a linearity error of <1%, the 330703-000-060-10-02-00 delivers precise measurements for early detection of misalignment or bearing wear, reducing unplanned downtime by up to 30%.

- Rugged Design: Hermetically sealed probe (AISI 304 stainless steel) and high-temperature-rated cables (FEP insulation) withstand extreme vibrations (50 g peak) and electromagnetic interference (EMI), ensuring stable performance in offshore platforms and refineries.

- Plug-and-Play Integration: Standardized output signals and compatibility with Bentley’s 3500 Monitoring System enable quick installation and calibration, saving 40% of setup time compared to legacy systems.

- Cost-Effective Maintenance: Full interchangeability of components eliminates the need for bench calibration, lowering long-term maintenance costs by 25%.

- Oil & Gas: Monitors axial displacement in compressors and pumps to prevent catastrophic failures in offshore platforms.

- Power Generation: Tracks shaft vibration in steam turbines to optimize energy production and reduce wear on critical components.

- Manufacturing: Detects imbalance in high-speed rotating machinery, such as centrifuges and conveyor systems, to improve production efficiency.

A petrochemical plant in the Middle East deployed the 330703-000-060-10-02-00 to monitor a gas compressor train. The sensor detected a 0.5 mm deviation in shaft displacement, indicating a potential seal failure. Maintenance teams replaced the seal during a scheduled outage, avoiding an estimated $300,000 in unplanned downtime and repair costs. The plant reported a 25% reduction in vibration-related incidents after integrating the sensor into its 3500 Monitoring System.

Compared to similar eddy current sensors, the 330703-000-060-10-02-00 offers:

- Wider Temperature Range: Operates 27°C hotter than most alternatives, making it suitable for extreme heat environments.

- Higher Signal Stability: Advanced signal conditioning reduces noise by 40%, ensuring reliable data in high-EMI settings.

- Deeper System Ecosystem: Native compatibility with Bentley’s 3500 Series provides access to predictive analytics (e.g., trend forecasting, fault diagnosis) without additional software.

BENTLY 330703-000-060-10-02-00

- Measurement Requirements: Choose the 330703-000-060-10-02-00 for applications requiring an 0–8 mm displacement range and high-frequency vibration monitoring (up to 8 kHz).

- Environmental Conditions: Prioritize this model for installations with temperatures exceeding +150°C or high vibration (e.g., gas turbine exhaust zones).

- System Compatibility: Ensure your monitoring system supports -20 to 0 VDC analog inputs or integrates with Bentley’s 3500 Series for full diagnostic capabilities.

- Cable Length: The 1-meter system length is ideal for compact setups; consult Bentley’s catalog for longer cable options (e.g., 5-meter or 9-meter configurations).

- Installation:

- Align the probe with the target surface at a nominal air gap (typically 2.5 mm) using Bentley’s calibration tools to ensure accuracy.

- Route sensor cables separately from high-voltage wires to minimize EMI interference.

- Calibration:

- Perform initial calibration with a certified displacement fixture and repeat every 12 months or after system modifications.

- Maintenance:

- Inspect the probe and cable for physical damage (e.g., abrasions, corrosion) during routine shutdowns, especially in high-vibration environments.

- Safety:

- De-energize the system and follow lockout/tagout procedures before handling the sensor to prevent electrical hazards.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

BENTLEY 330703-000-060-10-02-00 and other industrial automation spare parts. Visit our website

www.xydcontrol.com or contact us for sales and technical support, ensuring reliable solutions for your machinery monitoring needs.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide