Description

The

ABB APBU-44C 64669982 is a high-reliability

advanced power buffer unit designed for ABB’s industrial automation systems, serving as a critical component in maintaining uninterrupted power supply for control modules, sensors, and actuators. As part of ABB’s

Power Management Portfolio, the

APBU-44C 64669982 is engineered to bridge temporary power interruptions (up to 10 seconds) and stabilize voltage fluctuations in industrial environments, ensuring continuous operation of critical systems in manufacturing, energy, and process industries. This module integrates seamlessly with ABB’s AC 800M PLC and 800xA DCS platforms, providing real-time diagnostics and power health monitoring to prevent data loss or unexpected downtime.

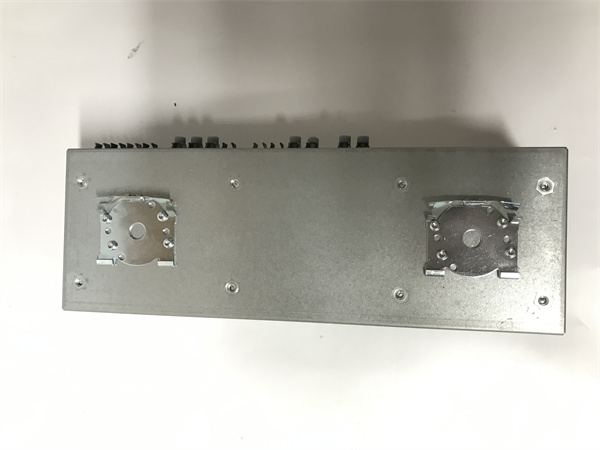

The APBU-44C 64669982 features a compact, DIN rail-mountable design (100 mm × 120 mm × 60 mm) and leverages advanced supercapacitor technology to deliver 44 Wh of backup energy, supporting up to 20 I/O modules or distributed control devices. Its 64669982 hardware variant includes enhanced surge protection (1.2/50 μs waveform) and EMC compliance (EN 61000-6-2/4), making it suitable for harsh environments with high electromagnetic interference, such as near heavy machinery or power transformers. Positioned as a robust and scalable solution, the module reduces reliance on large UPS systems for low-power automation components, optimizing space and cost in control panels while enhancing system resilience.

| Parameter Name |

Parameter Value |

| Product Model |

APBU-44C 64669982 |

| Manufacturer |

ABB |

| Product Type |

Power Buffer Unit (Supercapacitor-Based) |

| Backup Energy |

44 Wh |

| Input Voltage |

24 V DC (18–30 V DC, wide-range tolerance) |

| Output Voltage |

24 V DC (regulated, ±1%) |

| Backup Time |

Up to 10 seconds (at full load of 2 A) |

| Charge Time |

<5 minutes (from empty to full) |

| Operating Temperature |

-25°C to +60°C |

| Dimensions (W×H×D) |

100 mm × 120 mm × 60 mm |

| Mounting Method |

DIN rail (35 mm standard) |

| Certification |

CE, UL, IEC 61000-6-2/4, RoHS |

| Diagnostic Features |

LED indicators (power status, fault, charge level), dry contact alarms |

APBU-44C 64669982

The APBU-44C 64669982 ensures seamless transition to backup power during transient outages, critical for maintaining control system functionality in applications like pharmaceutical sterilization chambers, where even brief power loss could compromise product integrity. Its supercapacitor design offers longer cycle life (≥500,000 cycles) and faster charging compared to traditional battery-based solutions, making it ideal for frequent power fluctuation scenarios in manufacturing plants.

With a power density of 0.6 Wh/in³, the module occupies 50% less space than equivalent lead-acid battery units, optimizing panel real estate in compact automation setups like food packaging lines or small-scale chemical reactors. The 64669982 variant’s built-in voltage regulator ensures stable output under varying load conditions, preventing damage to sensitive electronics from voltage sags or spikes.

Real-time status indicators (green for normal operation, red for fault) and dry contact alarms enable quick identification of power issues, such as low charge levels or input voltage anomalies. The module integrates with ABB’s

800xA software to provide remote monitoring of backup energy levels and charge cycles, allowing predictive maintenance scheduling. For example, in a water treatment plant, the system can alert operators when supercapacitor health drops below 80%, triggering a proactive replacement before an outage occurs.

APBU-44C 64669982

The ABB APBU-44C 64669982 is essential in industries where uninterrupted control system operation is non-negotiable:

- Food and Beverage: Maintains power to filling machines and conveyor systems during transient outages, preventing product spoilage and ensuring compliance with hygiene standards. In a dairy plant, the module supports critical sensors monitoring pasteurization temperatures, avoiding costly batch reprocessing.

- Energy and Utilities: Stabilizes power for PLCs and RTUs in smart grid substations, ensuring continuous monitoring of circuit breakers and renewable energy inverters. Its wide temperature range makes it suitable for outdoor switchyards in both arctic and tropical climates.

- Oil and Gas: Provides backup power for emergency shutdown (ESD) systems in offshore platforms, where even short power interruptions could lead to safety incidents. The module’s EMC compliance ensures reliable operation near high-voltage motors and drilling equipment.

- Semiconductor Manufacturing: Supports cleanroom automation systems, such as wafer handling robots and deposition chamber controls, where power stability is critical to avoid defects in microchip production.

- ABB APBU-22C 64669981: A lower-capacity variant (22 Wh) for small-scale applications like single PLC cabinets or remote I/O nodes.

- ABB APBU-88C 64669983: A higher-capacity variant (88 Wh) for large control systems requiring extended backup times, such as central DCS rooms in refineries.

- ABB PS501: A 24 V DC power supply module, often paired with the APBU-44C to form a complete power management solution.

- ABB TB521: A terminal block accessory for secure power wiring, compatible with the module’s input/output terminals.

- ABB PM866AK01: An AC 800M control module that integrates with the APBU-44C to trigger safe shutdown procedures during prolonged outages.

Pre-installation preparation: Mount the APBU-44C 64669982 on a DIN rail in the control panel, ensuring at least 25 mm of clearance for heat dissipation. Connect the input power cable to a stabilized 24 V DC source using the TB521 terminal block, and link the output to the load (e.g., I/O modules) with shielded twisted-pair wiring. Configure dry contact alarms in the PLC to notify operators of low charge or fault conditions, and verify the module’s status via the front-panel LEDs.

Maintenance recommendations: Inspect the module’s LED indicators monthly to confirm proper charging and operation. In high-dust environments (e.g., cement plants), clean the ventilation slots quarterly with compressed air to prevent thermal derating. Replace the module every 5–7 years or after 500,000 charge cycles (whichever comes first) to maintain backup performance, as supercapacitor efficiency gradually declines over time. Use ABB’s Power Manager software to monitor charge cycle history and schedule replacements during planned maintenance windows.

ABB stands behind the APBU-44C 64669982 with a 5-year warranty, reflecting confidence in its supercapacitor technology and rugged construction. ABB’s global service network provides 24/7 technical support for power system design, installation, and troubleshooting, ensuring optimal performance in critical applications. The module’s compliance with international safety standards and rigorous testing (e.g., 10,000-cycle charge/discharge tests) guarantees long-term reliability. For customers requiring extended lifecycle support, ABB offers Spare Parts Retention Programs to ensure availability of the APBU-44C even after end-of-production, providing peace of mind for 20+ year system lifecycles.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide