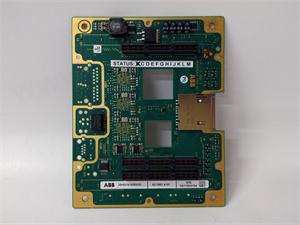

Description

The

ABB XDD501A101 is a high-performance

digital input module designed for industrial automation systems, serving as a critical interface for connecting discrete field devices to distributed control systems (DCS) or programmable logic controllers (PLCs). As part of ABB’s advanced

XDC800 control platform, the

XDD501A101 belongs to the

X-series I/O modules, engineered to deliver reliable signal acquisition and processing in harsh industrial environments. This module is specifically designed to convert binary signals from sensors, switches, and actuators into standardized digital inputs for real-time control and monitoring, ensuring seamless integration with ABB’s broader automation ecosystem.

Featuring a compact, modular design, the ABB XDD501A101 supports up to [16/32] isolated digital input channels, depending on the variant, with voltage compatibility for both low-level (24 VDC) and high-level (120/230 VAC) signals. Its core functions include noise filtering, signal conditioning, and fault diagnostics, ensuring accurate signal transmission even in high-electromagnetic-interference (EMI) environments. Positioned as a robust solution for process industries, manufacturing, and energy sectors, the module enhances system reliability by minimizing signal distortion and enabling proactive maintenance through real-time status feedback. By providing scalable, high-density I/O capabilities, the XDD501A101 optimizes control panel space and reduces wiring complexity, delivering tangible value in terms of installation efficiency and long-term operational stability.

| Parameter Name |

Parameter Value |

| Product Model |

XDD501A101 |

| Manufacturer |

ABB |

| Product Type |

Digital Input Module |

| Input Channels |

16 channels (24 VDC isolated) |

| Voltage Range |

18–30 VDC (low-level), 90–250 VAC (high-level variant) |

| Signal Filtering |

Software-selectable (1–100 ms debounce) |

| Contact Rating |

Dry contacts or solid-state sensors |

| Communication Interface |

Profibus DP, Ethernet/IP (via controller) |

| Power Supply |

24 VDC (from backplane) |

| Operating Temperature |

-40°C to +70°C |

| Dimensions (W×H×D) |

45 mm × 100 mm × 110 mm |

| Mounting Method |

DIN rail (TS 35) |

| Certification |

CE, UL, CSA, IEC 61131-2 compliant |

ABB XDD501A101

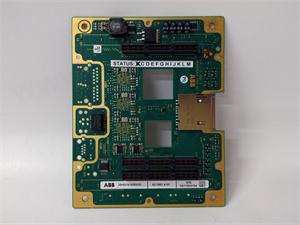

The ABB XDD501A101 stands out for its combination of ruggedness and intelligent signal management. Its isolated input channels protect against voltage spikes and ground loops, ensuring data integrity in noisy industrial environments. The module’s software-configurable filtering allows users to adjust debounce times based on application needs, reducing false triggers from transient noise—a critical feature for high-speed manufacturing or precision control systems.

A key advantage is the XDD501A101’s hot-swappable design, which enables module replacement without powering down the system, minimizing downtime during maintenance. The built-in LED indicators provide real-time status updates for each channel (e.g., signal presence, fault conditions), simplifying troubleshooting and reducing diagnostic time. The module’s high-density layout (16 channels in a compact form factor) optimizes space in control panels, making it ideal for retrofits or new installations with strict space constraints.

Additionally, the XDD501A101 integrates seamlessly with ABB’s Control Builder software, allowing centralized configuration and diagnostics via the XDC800 platform. This compatibility streamlines system commissioning and ensures consistent performance across multiple modules. The module’s wide temperature range and shock/vibration resistance further enhance its suitability for harsh environments, from outdoor oil and gas installations to high-temperature processing facilities.

The ABB XDD501A101 is widely deployed in industries requiring reliable discrete signal monitoring. In manufacturing, it connects proximity sensors, limit switches, and safety interlocks in assembly lines, enabling real-time tracking of machine status and ensuring compliance with safety protocols. For power generation, the module monitors circuit breaker positions, generator status signals, and emergency shutdown (ESD) inputs in power plants, supporting rapid response to critical events.

In the chemical and pharmaceutical sectors, the XDD501A101 interfaces with batch process control systems, detecting valve positions and flow switch states to ensure precise execution of complex recipes. It also excels in logistics and material handling, where it manages conveyor belt sensors, pallet detection switches, and automated storage system (AS/RS) signals for efficient warehouse automation.

By addressing the challenge of noisy or unreliable discrete signals, the module helps customers achieve higher system uptime, reduce maintenance costs, and improve operational efficiency. Its versatility across voltage ranges and protocols makes it a flexible choice for both legacy systems and modern, IP-based automation architectures.

ABB XDD501A101

- ABB XDD502A101: A digital output module complementary to the XDD501A101, providing 16-channel relay or solid-state outputs for control applications.

- ABB XTA586: A terminal block adapter for the XDD501A101, simplifying field wiring and enhancing mechanical stability.

- ABB XDC800 Controller: The primary control platform for the XDD501A101, offering advanced processing and Ethernet/IP connectivity.

- ABB XAI523: An analog input module for integrating sensor signals, often used alongside the XDD501A101 in hybrid control systems.

- ABB XPS-24V: A power supply module for the X-series I/O, ensuring stable 24 VDC delivery to the XDD501A101.

- ABB XSW520: A Ethernet switch module for expanding network connectivity in systems featuring the XDD501A101.

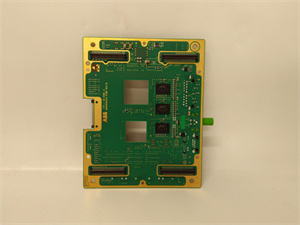

Pre-installation preparation: Ensure the ABB XDD501A101 is mounted on a DIN rail in a well-ventilated control panel, adjacent to compatible modules (e.g., XDC800 controller). Connect the 24 VDC power supply using shielded cables and terminate field device wires to the module’s terminal blocks, following the polarity and wiring diagram in the manual. Use Control Builder to configure channel parameters (e.g., voltage type, filtering time) and assign input addresses within the controller’s I/O map.

Maintenance recommendations: Regularly inspect the module’s LED indicators to verify proper signal reception and power status. Clean the module’s surface and ventilation slots with compressed air to prevent dust accumulation, which can affect thermal performance. Use the controller’s diagnostic tools to monitor channel health, such as open circuits or excessive noise levels, and replace faulty channels promptly using hot-swappable procedures. Periodically review firmware updates via ABB’s software platform to ensure compatibility with system upgrades and security patches.

ABB stands behind the XDD501A101 with a comprehensive quality assurance program, including rigorous testing for EMC compliance, temperature tolerance, and mechanical durability. The module is backed by a standard [X-year] warranty, covering defects in materials and workmanship. ABB’s global technical support team provides 24/7 assistance for configuration, troubleshooting, and replacement services, ensuring minimal disruption to operations. Customers can leverage ABB’s digital tools, such as remote diagnostics via the ABB Ability™ platform, to monitor module health and proactively address maintenance needs. With a focus on reliability and customer-centric service, ABB ensures the XDD501A101 delivers long-term value as a trusted component in industrial automation systems.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide