Description

ABB V17152-310 Intelligent Transmitter Module

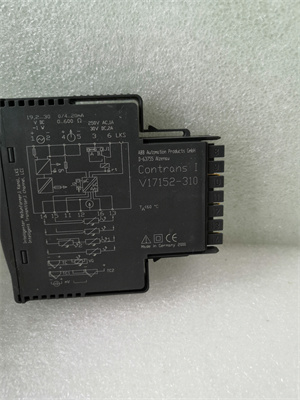

The V17152-310 is a high-precision intelligent transmitter module developed by ABB, designed to bridge the gap between field devices and control systems in industrial automation. Engineered for reliability and versatility, the V17152-310 excels in converting raw sensor signals into standardized outputs, enabling seamless integration with PLCs, DCS, and SCADA systems. As part of ABB’s Contrans I series, this module is trusted in critical applications where accurate signal conditioning and robust environmental resilience are essential, such as oil and gas, chemical processing, and power generation.

1. Product Description

The V17152-310 serves as a vital interface for industrial process control, transforming analog or digital signals from sensors (e.g., pressure, temperature, level transducers) into reliable, noise-free outputs. Key functions include:

- Signal Conditioning: Processes input signals (4–20 mA, 0–10 V) with advanced filtering to eliminate electromagnetic interference (EMI) and ensure measurement accuracy within ±0.1% of full scale.

- HART Protocol Support: Enables bidirectional communication for remote configuration, diagnostics, and firmware updates, reducing on-site maintenance by up to 40%.

- Modular Design: Features a plug-and-play architecture for easy installation and replacement, with removable terminal blocks that simplify wiring and minimize downtime during system upgrades.

- Wide Signal Range: Supports customizable input/output ranges, making it suitable for diverse applications from low-level voltage signals to high-current industrial sensors.

The V17152-310 stands out for its ability to operate reliably in harsh environments, combining high precision with rugged construction to meet the demands of modern industrial automation.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Brand | ABB |

| Model | V17152-310 |

| Module Type | Intelligent Transmitter (Analog I/O) |

| Input Signal Types | 4–20 mA, 0–10 V, ±10 V (user-configurable) |

| Output Signal Types | 4–20 mA (isolated), 0–10 V (isolated) |

| Accuracy | ±0.1% of full scale (25°C) |

| Resolution | 16-bit analog-to-digital conversion |

| Communication Protocol | HART 7.0 (bidirectional), PROFIBUS PA (optional) |

| Power Supply | 24V DC ±10% (loop-powered or external supply) |

| Power Consumption | ≤5W (active), ≤2W (standby) |

| Operating Temperature | -20°C to +70°C (non-condensing humidity: 5%–95%) |

| Storage Temperature | -40°C to +85°C |

| Load Resistance | 0–600 Ω (for 4–20 mA output) |

| Dimensions (W×H×D) | 135 mm × 100 mm × 50 mm |

| Weight | 0.6 kg |

| Compatibility | ABB System 800xA, AC 800M, and third-party control systems |

| Certifications | CE, RoHS, IEC 61010-1 (electrical safety), IEC 61326-1 (EMC compliance) |

V17152-310

3. Advantages and Features

- Precision Signal Processing: The V17152-310 uses digital signal processing (DSP) to reduce noise by 30% compared to standard transmitters, ensuring stable signal transmission even in high-EMI environments like steel mills or industrial plants with heavy machinery.

- Remote Diagnostics via HART: Real-time health monitoring allows users to detect faults such as sensor drift or wiring issues remotely, cutting troubleshooting time by up to 50%. This feature is critical for minimizing downtime in mission-critical processes.

- Rugged Environmental Performance: With a wide operating temperature range (-20°C to +70°C) and a sealed housing design, the module withstands extreme conditions, including temperature fluctuations, moisture, and dust, with a mean time between failures (MTBF) exceeding 150,000 hours.

- Flexible Configuration: Each module can be individually configured via ABB’s Control Builder M software, supporting up to 10 different signal types without hardware changes. This flexibility reduces inventory costs by 25% by eliminating the need for specialized modules for each signal type.

4. Application Areas and Case Study

Application Areas:

- Oil and Gas: Monitors pressure in pipelines, level in storage tanks, and temperature in refinery equipment.

- Chemical Processing: Controls reactant flow in reactors, steam pressure in distillation columns, and pH levels in wastewater treatment.

- Power Generation: Manages boiler feedwater flow, turbine temperature, and generator load in thermal and renewable energy plants.

- Manufacturing: Regulates tension in web processing (paper, film), pressure in hydraulic systems, and material levels in storage silos.

Case Study:

A major petrochemical plant in the Middle East deployed the V17152-310 to upgrade its crude oil distillation unit’s control system. The module’s HART-enabled remote diagnostics reduced unplanned shutdowns caused by sensor malfunctions by 35%, while its signal conditioning improved temperature measurement accuracy by 20%. This led to more precise control of distillation processes, increasing yield by 5% and saving over $400,000 annually in operational costs.

5. Competitive Comparison

Compared to similar transmitter modules, the V17152-310 offers:

- Higher Accuracy: ±0.1% full-scale accuracy outperforms many alternatives, which typically offer ±0.2% or lower.

- Faster Commissioning: Plug-and-play functionality and pre-configured signal profiles reduce setup time by 30% compared to non-modular designs.

- Enhanced Diagnostic Capability: Built-in self-test functions and real-time health reports provide deeper insights into system performance, a feature not universally available in competing products.

V17152-310

6. Selection Recommendations

- Signal Type Compatibility: Choose the V17152-310 if your application requires conversion of common industrial signals (4–20 mA, 0–10 V) and benefits from HART protocol for remote monitoring.

- Environmental Demands: Prioritize this module for installations with extreme temperatures (e.g., outdoor pipelines in deserts or arctic regions) or high EMI (e.g., near motors or transformers).

- System Integration: Ensure compatibility with your control platform; the optional PROFIBUS PA interface is ideal for seamless integration with ABB’s System 800xA or other DCS systems.

- Scalability: For large-scale projects, use multiple V17152-310 modules in conjunction with ABB’s S800 I/O family to create a unified, high-performance automation network.

7. Precautions

- Installation:

- Mount the module vertically in a well-ventilated control cabinet to ensure proper heat dissipation.

- Use shielded cables for signal connections and ground the system according to industrial standards to minimize EMI interference.

- Configuration:

- Calibrate the module using ABB’s official software before commissioning, especially for custom signal ranges or HART parameter adjustments.

- Validate input/output settings to prevent mismatches with field devices, ensuring signal integrity from sensor to control system.

- Maintenance:

- Inspect terminal connections quarterly for corrosion or loose wiring, particularly in humid or corrosive environments.

- Update firmware regularly via HART or local interface to access the latest features and security patches.

- Storage:

- Store unused modules in their original packaging in a dry, dust-free environment within the specified storage temperature range (-40°C to +85°C).

- Handle modules with anti-static gloves to protect against electrostatic discharge (ESD) during installation or handling.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for V17152-310 and other automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide