Description

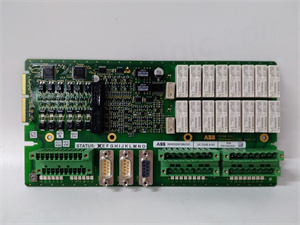

The

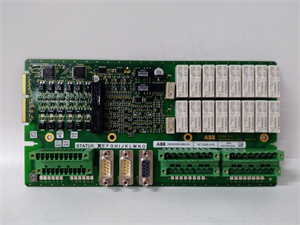

ABB UCD208A101 is a high-performance

control module designed for industrial automation systems, specifically engineered to deliver precise monitoring and control in complex process environments. As part of ABB’s advanced automation portfolio, the

UCD208A101 is built to enhance system reliability, scalability, and operational efficiency across a wide range of industries. This module serves as a critical interface between field devices and the control system, enabling seamless data exchange and real-time process management.

The ABB UCD208A101 is characterized by its robust design and versatile functionality, supporting multiple input/output (I/O) configurations to accommodate analog and digital signals. It integrates with ABB’s DCS (Distributed Control System) and PLC (Programmable Logic Controller) platforms, providing users with a unified solution for centralized control and decentralized intelligence. By combining high-speed processing with advanced diagnostics, the UCD208A101 minimizes downtime and ensures optimal performance in demanding industrial applications, making it an essential component for modern automation setups.

| Parameter Name |

Parameter Value |

| Product Model |

UCD208A101 |

| Manufacturer |

ABB |

| Product Type |

Control Module |

| Input Voltage Range |

24 V DC ±10% |

| Power Consumption |

≤5 W |

| Communication Protocol |

Modbus RTU, Profibus DP |

| I/O Channels |

16 analog inputs, 8 digital outputs |

| Signal Types |

4–20 mA, 0–10 V, dry contacts |

| Operating Temperature |

-20°C to +60°C |

| Storage Temperature |

-40°C to +85°C |

| Dimensions (W×H×D) |

100 mm × 150 mm × 50 mm |

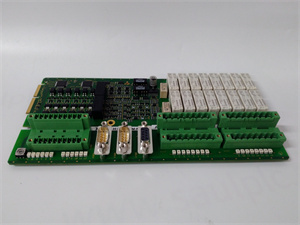

| Installation Method |

DIN rail mounting |

| Certification |

CE, UL, CSA |

ABB UCD208A101

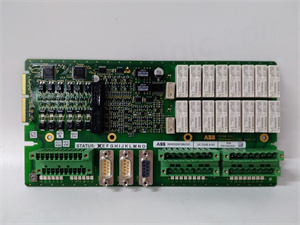

The ABB UCD208A101 stands out for its flexible I/O configuration, allowing users to customize signal types and channel assignments to match specific process requirements. Its built-in diagnostic capabilities provide real-time feedback on module health and signal integrity, reducing troubleshooting time and enhancing system availability. The module’s support for multiple communication protocols ensures compatibility with legacy and modern systems alike, making it a future-proof solution for industrial upgrades.

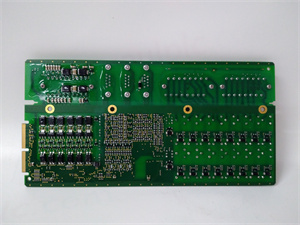

A key advantage of the UCD208A101 is its rugged construction, designed to withstand harsh industrial environments with resistance to vibration, moisture, and electromagnetic interference. This durability, combined with a wide operating temperature range, ensures reliable performance in challenging settings such as manufacturing plants, power generation facilities, and chemical processing sites. Additionally, the module’s hot-swappable design enables seamless maintenance without disrupting ongoing operations, minimizing downtime and improving overall system efficiency.

The

ABB UCD208A101 also prioritizes ease of integration, featuring plug-and-play functionality that simplifies installation and commissioning. Its intuitive configuration software allows engineers to quickly set up I/O mappings, calibration parameters, and communication protocols, reducing programming complexity and accelerating project timelines. By combining high-performance hardware with user-friendly software, the module delivers a balanced solution that meets both technical and operational demands.

ABB UCD208A101

The ABB UCD208A101 is ideally suited for industries requiring precise control and monitoring of complex processes. In manufacturing, it enables real-time adjustment of machine parameters, such as speed, temperature, and pressure, to ensure product quality and consistency. In energy and utilities, the module plays a critical role in managing power generation systems, monitoring fuel levels, and optimizing grid stability. It is also widely used in chemical and pharmaceutical production, where strict regulatory compliance and process accuracy are essential, supporting applications such as batch control, reactor monitoring, and quality assurance.

For water and wastewater treatment plants, the UCD208A101 helps monitor flow rates, chemical dosages, and pump operations, ensuring efficient treatment processes and environmental compliance. In food and beverage production, its hygienic design and reliable performance make it suitable for controlling packaging lines, sterilization processes, and inventory management systems. The module’s versatility also extends to oil and gas applications, where it supports upstream and downstream operations, including wellhead control, pipeline monitoring, and safety interlock systems.

By addressing the diverse needs of these industries, the ABB UCD208A101 provides a scalable and reliable control solution that adapts to evolving operational requirements, ensuring long-term value for users across sectors.

- ABB UCD205A101: A compact variant with fewer I/O channels, ideal for smaller-scale applications or distributed control setups.

- ABB UCD210A101: Features advanced analog input capabilities and higher precision for critical process control in industries like pharmaceuticals.

- ABB UCD208A201: Includes redundant communication ports for enhanced system reliability in mission-critical applications.

- ABB UCD208A102: Offers expanded digital I/O channels, suitable for systems requiring extensive discrete signal management.

- ABB UCD208A101-C: A certified version for use in hazardous environments, compliant with explosion-proof standards.

Pre-installation preparation: Ensure the installation environment meets the UCD208A101’s specifications for temperature, humidity, and electromagnetic compatibility. Verify the DIN rail is securely mounted and grounded. Connect power supply cables and I/O wiring according to the module’s terminal layout, ensuring proper shielding for analog signals to prevent interference. Configure communication parameters (e.g., baud rate, address) using ABB’s dedicated software before powering up the system.

Maintenance recommendations: Regularly inspect the UCD208A101 for physical damage or loose connections, especially in high-vibration environments. Use the module’s built-in diagnostics to monitor signal quality and power supply stability. Perform firmware updates as recommended by ABB to access the latest features and security patches. In the event of a fault, replace the module using hot-swappable procedures to avoid process interruptions, and retain the old module for diagnostic analysis.

ABB stands behind the UCD208A101 with a comprehensive quality assurance program, ensuring each module meets rigorous industry standards for performance and durability. The product is backed by a 24-month warranty, covering defects in materials and workmanship. ABB’s global technical support team provides timely assistance for installation, configuration, and troubleshooting, offering remote diagnostics and on-site service where required. Customers can access detailed documentation, software tools, and training resources to maximize the module’s capabilities. This commitment to quality and service ensures that the UCD208A101 delivers reliable, long-term performance, supporting customers in achieving their operational excellence goals.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide