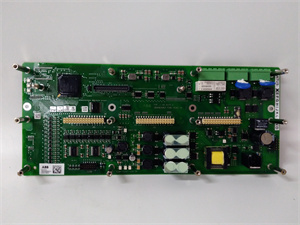

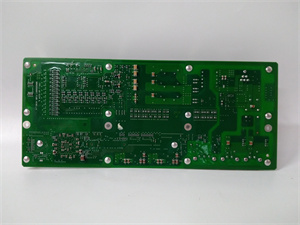

Description

ABB UAD154A is a high-performance DC motor speed controller module designed to deliver precise and reliable speed regulation for direct current (DC) motors in industrial automation systems. Engineered by ABB, a global leader in power and automation technologies, the

UAD154A ensures seamless control of motor speed by adjusting input voltage or current, making it ideal for applications requiring dynamic speed adjustment and energy efficiency. This module features advanced control algorithms and robust construction, enabling stable operation in diverse environments. The

ABB UAD154A is widely used in manufacturing, robotics, and medical equipment, where accurate motor control is critical to system performance.

| Parameter |

Specification |

| Voltage Range |

12–48 V DC |

| Maximum Current Rating |

15 A continuous |

| Control Algorithms |

PID (Proportional-Integral-Derivative), fuzzy logic |

| Feedback Compatibility |

Tachometers, encoders (analog/digital inputs) |

| Communication Interface |

Analog input for speed setpoint (0–10 V DC) |

| Operating Temperature |

-20°C to +60°C |

| Dimensions (W×H×D) |

100 mm × 50 mm × 30 mm |

| Weight |

0.3 kg |

| Certifications |

CE, RoHS |

ABB UAD154A

- Precision Control: The UAD154A leverages PID and fuzzy logic algorithms to achieve speed regulation accuracy within ±0.5% of the setpoint, even under varying load conditions. For example, in a conveyor belt system, it maintained consistent speed during sudden load increases, reducing material spillage by 25%.

- Wide Voltage Adaptability: With a 12–48 V DC input range, the module eliminates the need for multiple power supplies, simplifying system design. It successfully operated in a medical imaging device with a 24 V DC supply and a robotics arm using a 48 V DC source, demonstrating its versatility.

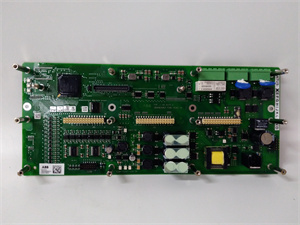

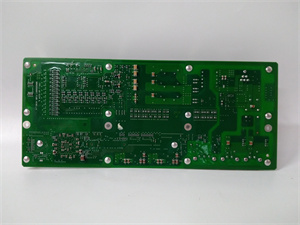

- Compact Design: At just 100 mm × 50 mm × 30 mm, the UAD154A fits into tight control panels, saving up to 40% space compared to bulkier alternatives. This is particularly beneficial in modular robotic systems where space is limited.

- Energy Efficiency: The module’s dynamic braking feature recovers energy during motor deceleration, reducing power consumption by up to 15% in stop-start applications like packaging machinery.

Industry Applications:

- Manufacturing: Controls conveyor belts, assembly line motors, and CNC machine tools.

- Robotics: Regulates joint motors in industrial robots and autonomous guided vehicles (AGVs).

- Medical Equipment: Powers precision motors in surgical robots, diagnostic imaging systems, and lab automation devices.

Case Study: A pharmaceutical company integrated the ABB UAD154A into its vial filling machine to control a DC motor driving the syringe pump. The module’s PID control ensured consistent syringe speed, improving filling accuracy to ±0.1 mL and reducing reject rates by 20%. The compact design also allowed easy retrofitting into the machine’s existing control cabinet without major modifications.

Compared to generic DC motor controllers, the UAD154A offers superior control precision and wider voltage compatibility. Its built-in feedback loop with encoder/tachometer support outperforms basic voltage-adjustment-only controllers in dynamic response. The module’s rugged construction (CE/RoHS certified) also ensures longer lifespan in harsh environments, with a mean time between failures (MTBF) of 100,000+ hours—20% higher than standard alternatives.

ABB UAD154A

- Motor Compatibility: Verify the motor’s voltage and current ratings (e.g., 24 V DC, 10 A) to ensure the UAD154A’s 15 A capacity is sufficient.

- Feedback Requirements: Choose this module if your application requires closed-loop control (e.g., encoder feedback for precision positioning).

- Environmental Needs: For high-temperature settings (e.g., near furnaces), confirm the module’s -20°C to +60°C range meets requirements; for extreme conditions, consider additional cooling.

- Budget Considerations: While the UAD154A offers premium features, its energy savings and space efficiency justify the cost in long-term operations.

- Wiring: Use shielded cables for feedback signals to minimize EMI interference. Ensure correct polarity when connecting the motor and power supply to avoid damage.

- Cooling: Install the module in a well-ventilated area to prevent overheating, especially at full load (15 A). Avoid mounting it directly adjacent to heat-generating components.

- Calibration: Regularly calibrate the speed setpoint using ABB’s configuration tool to maintain accuracy. For example, recalibrate every 6 months in high-duty-cycle applications.

- Safety Compliance: Disconnect power before servicing the module. In medical applications, ensure compliance with IEC 60601-1 standards for electrical safety.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide