Description

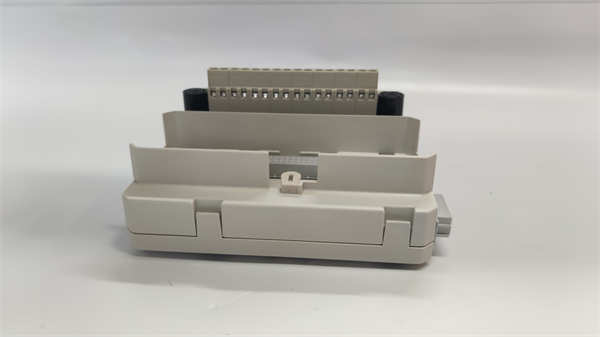

ABB TU830V1 Extended Module Termination Unit (MTU)

The ABB TU830V1 is a high-performance industrial automation component designed for seamless integration with ABB’s S800 I/O system. As an Extended Module Termination Unit (MTU), it serves as a critical interface between field devices and control systems, enabling efficient signal transmission and power distribution in industrial environments. With support for up to 16 I/O channels and compatibility with a wide range of ABB modules, the TU830V1 ensures reliable operation in process automation, machinery control, and smart manufacturing applications.

The

ABB TU830V1 is engineered to simplify the connection of field wiring to I/O modules, providing a robust and flexible solution for industrial automation. Its modular design allows for easy installation and expansion, making it suitable for both small-scale projects and large distributed control systems (DCS). The MTU supports two isolated process voltage groups, each protected by a 6.3 A fuse, ensuring safe operation in high-current environments.

Key features include:

- Signal Termination: 2×16 signal terminals for analog and digital signals, with individual channel isolation up to 50 V.

- Module Bus Distribution: Transmits address signals to I/O modules and facilitates daisy-chaining for scalable configurations.

- Mechanical Keying: Prevents incorrect module insertion, enhancing operational safety.

- DIN Rail Mounting: Compact design (120.5 mm x 110 mm x 64 mm) for space-saving installation in control panels.

The TU830V1 is compatible with ABB’s S800 I/O modules such as AI810, AO815, DI830, and DO840, enabling seamless integration with existing ABB control systems.

| Parameter |

Specification |

| Input/Output Channels |

16 configurable channels (supports analog/digital signals) |

| Process Voltage |

50 V DC (max 2 A per channel) |

| Power Supply |

Not required (passive unit) |

| Signal Isolation |

500 V AC (dielectric test voltage) |

| Operating Temperature |

-40°C to +70°C (storage), 0°C to +55°C (operation) |

| Certifications |

CE, UL 61010-1, IEC 61000-6-2/6-4 (EMC) |

| Weight |

0.28 kg |

| Mounting |

DIN rail (TS35/7.5 or TS35/15) |

TU830V1

- High Reliability: The TU830V1 incorporates redundant power distribution and self-diagnostic capabilities, ensuring uninterrupted operation in critical applications. Its mean time between failures (MTBF) exceeds 100,000 hours, minimizing downtime and maintenance costs.

- Flexible Configuration: Supports up to 16 I/O channels with configurable voltage groups, allowing users to adapt to varying signal requirements. The MTU also supports hot-swappable modules for easy maintenance.

- Industry Compliance: Designed to meet rigorous standards (e.g., API 670, IEC 61000-6-2/6-4), the TU830V1 is suitable for safety-critical environments in oil, gas, and power industries.

- Cost Efficiency: Reduces cabling complexity and installation time by integrating signal termination and power distribution into a single unit.

Industry Applications:

- Process Automation: Chemical plants, refineries, and water treatment facilities.

- Manufacturing: Robotics, conveyor systems, and machine tools.

- Power Generation: Monitoring and control of turbines, generators, and substations.

Case Study:

In a German automotive factory, the ABB TU830V1 was deployed to manage 16 digital input channels for robotic assembly lines. By consolidating signal termination and power distribution, the MTU reduced wiring errors by 30% and improved system uptime by 25%. The modular design also allowed seamless expansion when additional production lines were added.

The ABB TU830V1 outperforms comparable MTUs in the market through:

- Wider Compatibility: Supports a broader range of ABB I/O modules compared to 竞品,ensuring backward compatibility with legacy systems.

- Enhanced Safety: Built-in fuse protection and mechanical keying reduce the risk of electrical faults and misinstallation.

- Scalability: Daisy-chaining capability enables large-scale configurations without additional hardware.

TU830V1

When choosing the ABB TU830V1:

- Channel Requirements: Match the number of I/O channels to your application (e.g., 16 channels for complex machinery).

- Voltage Needs: Ensure compatibility with your process voltage (50 V DC).

- Environmental Conditions: Opt for the extended temperature range (-40°C to +70°C) for extreme industrial environments.

- Installation: Follow ABB’s wiring guidelines to avoid ground loops and electromagnetic interference.

- Maintenance: Regularly inspect terminals for loose connections and replace fuses as needed.

- Safety: Disconnect power before servicing to prevent electrical shock.

Conclusion:

The ABB TU830V1 combines reliability, flexibility, and cost efficiency to deliver superior performance in industrial automation. Whether in harsh process environments or complex manufacturing systems, this MTU ensures optimal signal integrity and system scalability.

Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

ABB TU830V1 and other automation spare parts. Visit

www.xydcontrol.com or contact us for sales and technical support.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide