Description

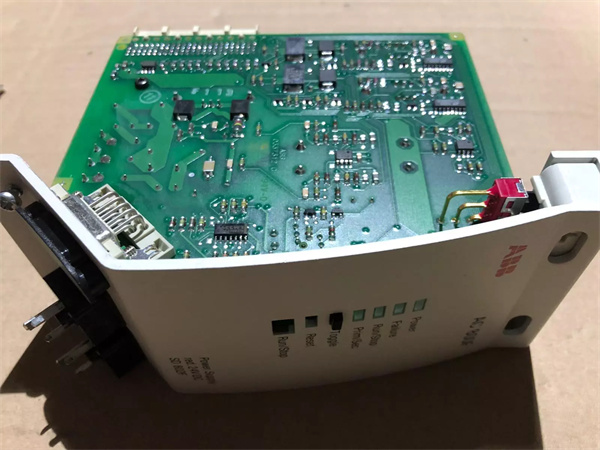

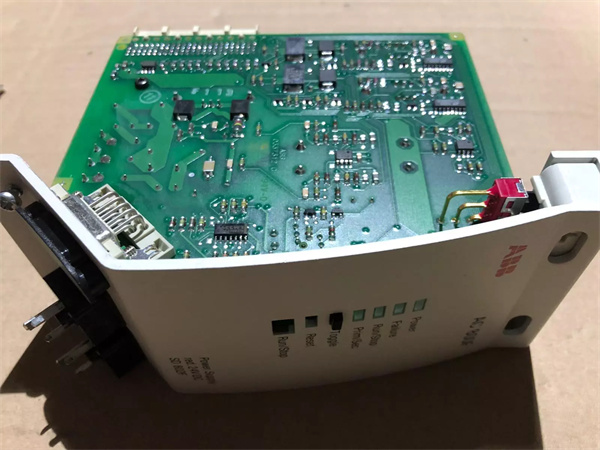

The

ABB SD802F is a significant and highly useful power supply module. This SD802F module is specifically designed to offer a stable 24V DC power output, playing a crucial role in industrial control systems. It ensures the uninterrupted operation of various automation devices and equipment. The SD802F is engineered to maintain consistent performance across a wide range of operating conditions. With its advanced technology, it effectively filters out electrical noise and disturbances, providing a clean and reliable power source. The SD802F also features overcurrent protection and short-circuit protection mechanisms, safeguarding connected devices from potential damage. Moreover, the SD802F is designed for easy integration into existing industrial setups, making it a convenient choice for system upgrades or new installations.

- Input Voltage Range: Typically supports a wide range of input voltages, such as 85 – 264V AC or 100 – 370V DC.

- Output Voltage: Fixed at 24V DC.

- Output Current: Capable of delivering a specified maximum output current, for example, up to a certain number of amperes depending on the model (e.g., 5A or 10A).

- Efficiency: High efficiency, usually above a certain percentage (e.g., 85% or higher) under typical operating conditions.

- Operating Temperature: Can operate within a temperature range, say -20°C to +60°C.

- Communication Interface: May support communication interfaces like RS485 or Modbus for monitoring and control purposes.

- High Reliability: The SD802F is built with high-quality components and undergoes strict quality control measures. In industrial environments where power fluctuations and electrical interference are common, it has been proven to operate stably for long periods. For instance, in a large-scale manufacturing plant with complex electrical systems, the SD802F has continuously provided stable power supply for over a year without any failures, ensuring the smooth running of production lines.

- Redundant Capability: One of the outstanding features of the SD802F is its ability to be used in redundant configurations. This means that in case one power supply module fails, the other can take over seamlessly, maintaining the power supply to critical equipment. This significantly reduces the risk of system downtime and enhances the overall reliability of the industrial control system.

- Energy Efficiency: The SD802F is designed to be energy-efficient, helping to reduce power consumption and lower operating costs. Its high efficiency ensures that less energy is wasted as heat during the power conversion process. This is not only beneficial for cost savings but also aligns with environmental sustainability goals.

- Application Areas: The SD802F is applicable in a wide variety of industries. It is commonly used in the manufacturing industry for powering automated machinery, robotic systems, and control panels. In the energy sector, it is utilized in power generation plants, substations, and renewable energy installations. Additionally, it finds applications in the chemical industry, water treatment facilities, and transportation systems.

- Application Case: In a large chemical processing plant, the SD802F was installed in the control room to power the distributed control system (DCS). Due to the harsh chemical environment and frequent electrical surges in the plant, the reliability of the power supply was of utmost importance. The SD802F’s redundant capability ensured that even during unexpected power failures or module malfunctions, the DCS continued to operate without interruption, allowing the plant operators to maintain control over the chemical processes and prevent any potential safety hazards or production losses.

Compared to some other power supply modules available in the market, the SD802F has several distinct advantages. Its redundant capability is more advanced and reliable, offering better protection against system failures. In terms of efficiency, the SD802F often outperforms similar products, resulting in lower energy consumption and cost savings. Additionally, the SD802F’s compatibility with a wide range of industrial communication interfaces makes it more versatile and easier to integrate into complex control systems compared to some other products that may have limited communication options.

- Compatibility: When choosing the SD802F, ensure that it is compatible with the existing electrical systems and devices in your industrial setup. Check the input and output voltage requirements, as well as the communication interfaces, to make sure it can work seamlessly with other components.

- Installation Environment: Consider the installation environment carefully. If the environment is prone to high temperatures, humidity, or dust, make sure the SD802F is rated for such conditions. You may need to take additional measures such as installing proper ventilation or protection enclosures.

- Power Requirements: Evaluate the power requirements of your equipment accurately. Choose an SD802F model with an appropriate output current capacity to ensure that it can meet the power needs of all the connected devices. Also, consider future expansion needs to avoid the need for frequent upgrades.

- Safety Precautions: When installing and using the SD802F, always follow the safety guidelines provided in the user manual. Make sure to turn off the power supply before installation or maintenance to prevent the risk of electric shock.

- Maintenance: Regularly inspect the SD802F for any signs of damage or abnormal operation. Clean the module periodically to remove dust and debris that could affect its performance. Check the connections and cables regularly to ensure they are secure and in good condition.

Shanxi Xinyeda International Trading Co., Ltd. is your reliable partner. We provide SD802F and sales and technical support for other automation spare parts. Please visit our website

www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide