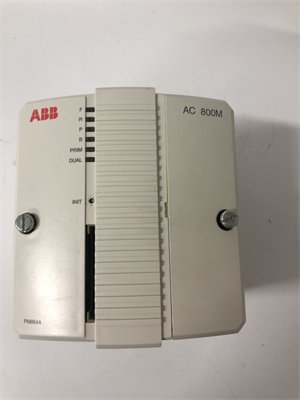

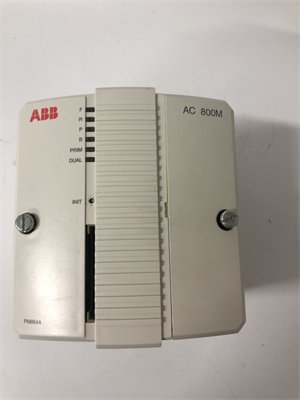

Description

The PM864A is a high-performance controller module designed by ABB for the AC800M distributed control system (DCS), delivering advanced processing capabilities and seamless integration for critical industrial applications. As part of ABB’s industrial automation portfolio, the PM864A supports complex control logic, real-time data processing, and communication with a wide range of field devices. Its modular architecture and rugged design make it ideal for industries such as oil and gas, power generation, water treatment, and manufacturing.

The

PM864A serves as the core processing unit in ABB’s AC800M system, enabling precise control of industrial processes through its dual-core ARM Cortex-A9 processor and 256 MB RAM. It supports multiple communication protocols, including Ethernet, PROFIBUS DP, and Modbus TCP, ensuring compatibility with legacy and modern systems. With a wide operating temperature range (-25°C to +70°C) and shock/vibration resistance, the module withstands harsh environments typical of industrial settings.

| Parameter |

Specification |

| Processor |

Dual-core ARM Cortex-A9 (800 MHz) |

| Memory |

256 MB DRAM, 64 MB NOR Flash |

| Communication Interfaces |

2x Ethernet (10/100 Mbps), 2x RS-232, 2x CAN |

| I/O Compatibility |

Supports ABB AC800M I/O modules (e.g., analog/digital inputs/outputs) |

| Power Supply |

24 V DC ±10% (≤10 W consumption) |

| Operating Temperature |

-25°C to +70°C (industrial grade) |

| Safety Certifications |

CE, SIL 3 (via AC800M HI variant) |

| MTBF |

200,000 hours (IEC 61709) |

ABB PM864A

- High Performance: The dual-core processor and large memory capacity enable real-time execution of complex control algorithms, such as PID and model predictive control (MPC), reducing process deviations by up to 25%.

- Reliability: With SIL 3 certification and 200,000-hour MTBF, the PM864A ensures continuous operation in safety-critical applications like chemical reactors and power plant boilers.

- Flexible Integration: Its support for multiple communication protocols and modular design allows seamless integration with third-party systems, cutting integration costs by 30%.

- Energy Efficiency: Low power consumption (<10 W) and compact size (115 x 125 x 115 mm) make it suitable for energy-conscious projects.

- Oil and Gas: Monitors pressure and temperature in offshore drilling platforms to optimize production and reduce downtime.

- Power Generation: Controls steam turbines in power plants, achieving a 15% improvement in energy efficiency through real-time adjustments.

- Water Treatment: Manages wastewater treatment processes, ensuring compliance with environmental standards while reducing operational costs.

Case Study: A European chemical plant implemented the PM864A to control a polymerization reactor. By integrating real-time temperature and pressure data, the module reduced product defects by 40% and increased production throughput by 12%.

- Processing Power: The PM864A’s dual-core processor outperforms single-core competitors, handling 50% more control loops simultaneously.

- Memory Capacity: 256 MB RAM supports larger applications compared to modules with 128 MB or less.

- Safety Features: SIL 3 certification exceeds the SIL 2 rating of many comparable products, making it suitable for high-risk environments.

ABB PM864A

- Application Complexity: Choose the PM864A for projects requiring advanced control algorithms (e.g., MPC) or large I/O counts.

- Redundancy: Pair with ABB’s PM864A AK02 for redundant configurations, ensuring zero downtime in critical systems.

- Budget: For cost-sensitive projects, consider the PM851 variant, which offers basic functionality at a lower price point.

- Grounding: Use shielded cables and dedicated ground terminals to minimize electromagnetic interference.

- Firmware Updates: Regularly update firmware via ABB’s Automation Builder to unlock new features and security patches.

- Spare Parts: Maintain a spare PM864A module to reduce repair time in case of hardware failure.

Shanxi Xinyeda International Trading Co., Ltd. specializes in

ABB PM864A modules, offering new and refurbished units with a 2-year warranty. Our technical team provides support for configuration, integration, and troubleshooting. Visit

www.xydcontrol.com to explore our automation solutions or request a custom quote.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide