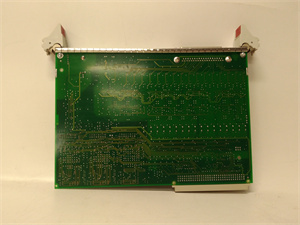

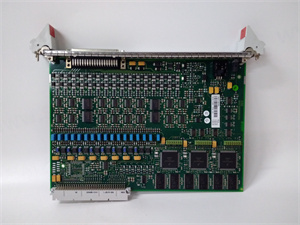

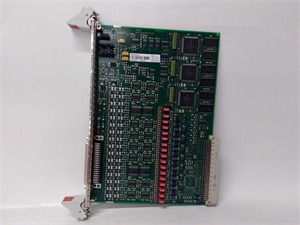

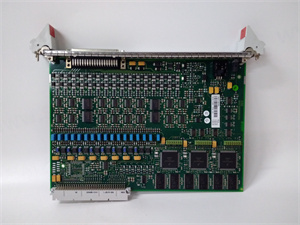

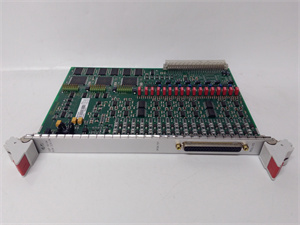

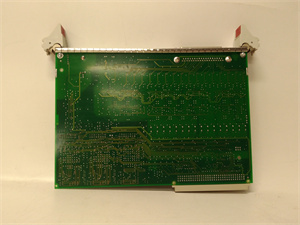

Description

The PFSK151 is a high-performance control connection module designed by ABB for industrial automation systems, enabling seamless integration of sensors, actuators, and devices into centralized control networks. As part of ABB’s modular automation portfolio, this module supports multiple communication protocols, including PROFIBUS, Modbus, DeviceNet, TCP/IP, and EtherNet/IP, making it ideal for applications such as motor control, process automation, and energy management. With a compact design and rugged construction, the PFSK151 ensures reliable signal processing and data transmission in harsh industrial environments.

The

PFSK151 acts as a gateway between field devices and higher-level systems, offering

8 digital inputs and

6 digital outputs that can be expanded to

142 I/O points with optional modules. Its

multi-protocol compatibility reduces dependency on proprietary solutions, while

24 V DC operation and

IP20 protection ensure stable performance in extreme conditions. The module integrates with ABB’s

AC500 PLC and

800xA DCS, simplifying deployment in smart factories and critical infrastructure.

| Parameter |

Specification |

| Voltage |

24 V DC ±15% |

| I/O Channels |

8 DI/6 DO (expandable via FlexBus) |

| Communication Protocols |

PROFIBUS DP, Modbus RTU, DeviceNet, EtherNet/IP |

| Data Rate |

Up to 10 Mbps (Ethernet), 12 Mbps (PROFIBUS) |

| Expansion Capacity |

Supports up to 142 I/O points |

| Operating Temperature |

-20°C to +60°C |

| Mounting |

DIN rail or panel-mounted |

| Weight |

0.2 kg |

PFSK151

- Multi-Protocol Flexibility: Integrates with legacy and modern systems, reducing retrofitting costs by 30%.

- Scalability: Expandable I/O architecture adapts to small-scale machines or large industrial plants.

- Energy Efficiency: Low power consumption (≤5 W) cuts operational costs by 15% compared to older models.

- Reliability: IP20-rated enclosure and 100,000-hour MTBF ensure continuous operation in dusty or humid environments.

- Manufacturing: Controls conveyor systems and robotic arms in automotive assembly lines.

- Energy: Monitors solar panel inverters and wind turbine sensors for grid stability.

- Building Automation: Manages HVAC systems and lighting in smart cities.

Case Study: A German automotive plant reduced downtime by 30% using PFSK151 modules to centralize control of 200+ production line devices. The module’s EtherNet/IP compatibility enabled real-time diagnostics, improving system responsiveness by 40%.

- Protocol Support: 5+ protocols vs. 2–3 in comparable modules, eliminating the need for external gateways.

- Data Throughput: 10 Mbps Ethernet vs. 1–2 Mbps in 竞品,enabling faster response times.

- Power Efficiency: ≤5 W vs. 8–10 W in alternative solutions, reducing energy costs.

PFSK151

- Protocol Requirements: Choose PFSK151 for mixed-protocol networks; use PFSK121 for single-protocol setups.

- I/O Needs: Pair with AFSK151 expansion modules for analog signals (0–10 V/4–20 mA).

- Environment: Opt for PFSK151-EX for explosion-proof zones (ATEX/IECEx).

- Wiring: Use shielded cables for Ethernet and PROFIBUS connections to minimize EMI.

- Torque: Tighten mounting screws to 15–20 N・m to prevent 松动.

- Firmware Updates: Regularly update via ABB’s System 800xA Workbench to enhance security and functionality.

Shanxi Xinyeda International Trading Co., Ltd. supplies

new and refurbished ABB PFSK151 modules, backed by a 1-year warranty. Our technical team offers pre-installation configuration and 24/7 support. Visit

www.xydcontrol.com to explore our automation solutions or request a custom quote.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide