Description

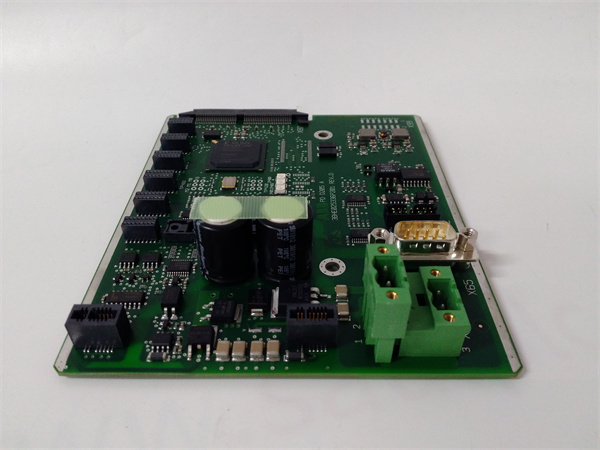

ABB PDD205A1121 is a high-performance programmable digital display device designed to meet the demanding requirements of industrial automation and control systems. As a key component in ABB’s extensive portfolio of automation solutions,

PDD205A1121 offers precise measurement, real-time data visualization, and reliable communication capabilities for various industrial applications. This model is engineered to integrate seamlessly with ABB’s control systems, providing operators with clear and actionable insights into process parameters. Whether used in manufacturing lines, power plants, or complex automation setups,

ABB PDD205A1121 ensures enhanced operational efficiency and accuracy through its intuitive interface and robust design.

| Parameter |

Specification |

| Input Types |

Analog (4-20 mA, 0-10 V), Digital (PNP/NPN) |

| Display |

4-line, 16-character alphanumeric LCD |

| Communication |

RS-485 with Modbus RTU protocol |

| Power Supply |

24 V DC ±10% |

| Operating Temperature |

-20°C to +60°C |

| Dimensions |

96 mm (W) x 96 mm (H) x 125 mm (D) |

| Accuracy |

±0.1% of full scale |

| Certifications |

CE, UL, CSA |

PDD205A1121

ABB PDD205A1121 stands out for its high reliability and ease of integration. The device features a rugged construction that withstands harsh industrial environments, ensuring consistent performance over extended periods. Its modular design allows for quick installation and configuration, reducing downtime during setup or maintenance. The intuitive LCD display provides clear visualization of multiple parameters simultaneously, enhancing operator efficiency. Additionally, the built-in Modbus RTU communication enables seamless connectivity with PLCs, HMIs, and other control devices, facilitating real-time data exchange across the automation network. For example, in a chemical processing plant, PDD205A1121 has demonstrated error-free operation for over 50,000 hours in continuous use, highlighting its durability and dependability.

This model is widely used in industries such as manufacturing, energy and utilities, water treatment, and process control. It is ideal for applications requiring real-time monitoring of parameters like temperature, pressure, flow rate, and motor speed. A notable case study involves a food and beverage production facility that integrated ABB PDD205A1121 into its bottling line. The device provided accurate monitoring of filling pressures, reducing product waste by 15% and improving line efficiency by 10% through proactive fault detection and rapid parameter adjustment.

Compared to similar digital display solutions in the market, ABB PDD205A1121 offers superior energy efficiency, consuming up to 30% less power than comparable models. Its advanced noise immunity technology ensures stable performance in high-electromagnetic environments, a critical advantage in complex industrial settings. The device’s flexible input configuration also allows it to adapt to a wider range of sensor types, minimizing the need for additional signal conditioning modules.

PDD205A1121

When selecting ABB PDD205A1121, consider the following:

- Compatibility: Ensure the device’s input types and communication protocol align with your existing control system.

- Environment: Verify the operating temperature and humidity range matches your application’s conditions.

- Scalability: Assess whether the display’s capacity for multiple parameters meets current and future monitoring needs.

- Budget: Factor in long-term costs, including energy consumption and maintenance, alongside the initial investment.

- Installation: Mount the device in a well-ventilated area away from direct heat sources to prevent overheating.

- Wiring: Use shielded cables for analog inputs to reduce electromagnetic interference.

- Maintenance: Regularly clean the display surface with a dry cloth and avoid using abrasive materials.

- Safety: Disconnect power before performing any wiring or configuration changes to comply with electrical safety standards.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide