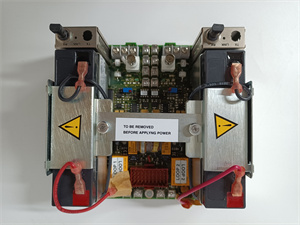

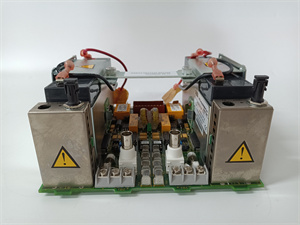

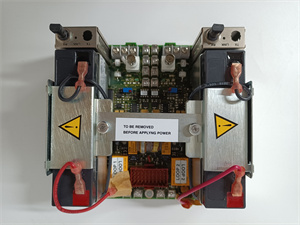

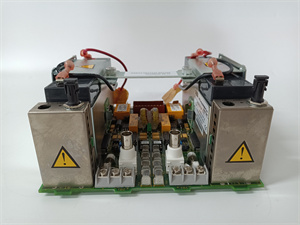

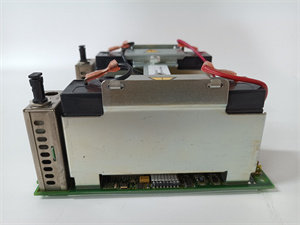

Description

The

ABB NTCF22 is a high-performance

temperature control module designed for industrial automation systems, serving as a critical component in process control and monitoring applications. As part of ABB’s advanced automation portfolio, the

NTCF22 is engineered to deliver precise temperature regulation and reliable data acquisition, making it an ideal solution for industries requiring tight control over thermal processes. This module integrates seamlessly with ABB’s PLC and DCS systems, ensuring compatibility with existing infrastructure while enhancing operational efficiency. The

ABB NTCF22 supports multiple thermocouple and RTD input types, allowing flexibility in connecting to various temperature sensors, and features advanced diagnostics to minimize downtime and improve system maintainability. Positioned as a robust and versatile component, the

NTCF22 empowers manufacturers to achieve optimal temperature control, reduce energy consumption, and maintain product quality across diverse applications.

| Parameter Name |

Parameter Value |

| Product Model |

NTCF22 |

| Manufacturer |

ABB |

| Product Type |

Temperature Control Module |

| Input Types |

Thermocouples (J, K, T, E, R, S), RTDs (Pt100, Pt1000) |

| Channels |

8 isolated channels |

| Input Resolution |

0.1°C (depending on sensor type) |

| Accuracy |

±0.2% of full scale |

| Communication Protocol |

Modbus RTU, Profibus DP |

| Power Supply |

24 V DC ±10% |

| Operating Temperature |

-20°C to +60°C |

| Storage Temperature |

-40°C to +85°C |

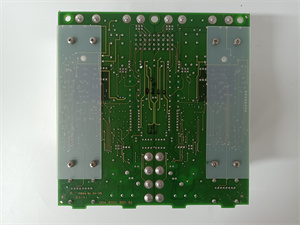

| Dimensions (W×H×D) |

100 mm × 150 mm × 80 mm |

| Installation Method |

DIN rail mountable |

NTCF22

The ABB NTCF22 stands out for its versatile input compatibility and precision control capabilities, supporting a wide range of temperature sensors to adapt to diverse industrial setups. Its 8 isolated channels prevent cross-interference, ensuring reliable data acquisition even in high-noise environments. The module’s advanced auto-calibration function minimizes drift over time, reducing the need for frequent manual adjustments and enhancing long-term accuracy.

A key advantage is its seamless integration with industrial networks, featuring dual communication protocols (Modbus RTU and Profibus DP) that enable real-time data exchange with higher-level control systems. This connectivity allows for remote monitoring and configuration, improving operational agility and reducing response times to process variations.

The

NTCF22 also prioritizes

durability and ease of maintenance, with a rugged design capable of withstanding harsh industrial conditions and a plug-and-play interface that simplifies installation and replacement. Built-in diagnostic tools provide real-time status updates, helping operators identify and resolve issues proactively to avoid costly downtime.

NTCF22

The ABB NTCF22 is widely applicable in industries where precise temperature control is critical, including:

- Manufacturing and Process Industries: Ideal for regulating temperatures in furnaces, ovens, and chemical reactors, ensuring consistent product quality and process safety.

- Food and Beverage Production: Used in pasteurization, cooking, and packaging lines to maintain hygienic standards and optimize production efficiency.

- Pharmaceuticals and Biotechnology: Supports strict temperature control in sterilization processes, laboratory equipment, and pharmaceutical manufacturing to comply with regulatory requirements.

- Energy and Utilities: Applied in power plants and HVAC systems to monitor and control thermal systems, enhancing energy efficiency and equipment longevity.

- Automotive and Electronics: Used in component testing, soldering processes, and quality control to ensure thermal stability and performance.

In each application, the NTCF22 addresses the challenge of maintaining precise temperature profiles while offering the flexibility to adapt to changing process requirements, making it a reliable choice for both retrofitted and new automation systems.

- ABB NTCF11: A compact, entry-level temperature control module with 4 channels, suitable for smaller-scale applications.

- ABB NTCF33: A high-channel-density model with 16 channels, designed for large-scale industrial systems requiring extensive temperature monitoring.

- ABB TC500: A temperature controller series offering standalone operation, complementary to the NTCF22 for distributed control setups.

- ABB PT100 Sensors: Compatible RTD sensors for precise temperature measurement, enhancing the NTCF22’s input flexibility.

- ABB AC500 PLC Series: Integrated control platforms that pair with the NTCF22 for centralized automation and data management.

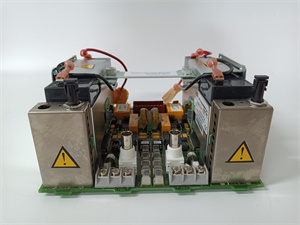

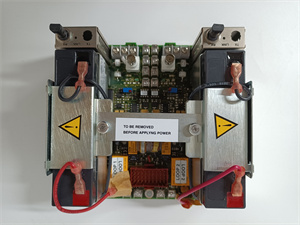

Pre-installation preparation: Ensure the installation environment meets the NTCF22’s operating temperature and power requirements. Mount the module on a DIN rail in a controlled cabinet, leaving adequate space for heat dissipation. Connect power and sensor cables according to the wiring diagram, ensuring proper grounding to minimize electromagnetic interference. Verify communication settings (baud rate, address) match the host system before powering up.

Maintenance recommendations: Regularly inspect the module for physical damage or loose connections, especially in high-vibration environments. Use the built-in diagnostic functions to monitor channel status and calibration levels. Periodically clean the module to prevent dust accumulation, which may affect thermal performance. If replacement is needed, power down the system and use the quick-release mechanism for easy removal and installation of the new NTCF22 module.

ABB stands behind the NTCF22 with a comprehensive quality assurance program, ensuring the module meets rigorous industry standards for reliability and performance. The product is backed by a standard warranty covering material and workmanship defects, with optional extended service plans available for enhanced protection. ABB’s global technical support team provides 24/7 assistance for troubleshooting, configuration, and system integration, ensuring minimal downtime and maximum operational uptime. Customers can rely on ABB’s decades of expertise in industrial automation to deliver a product that combines cutting-edge technology with robust durability, providing long-term value and peace of mind.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide