Description

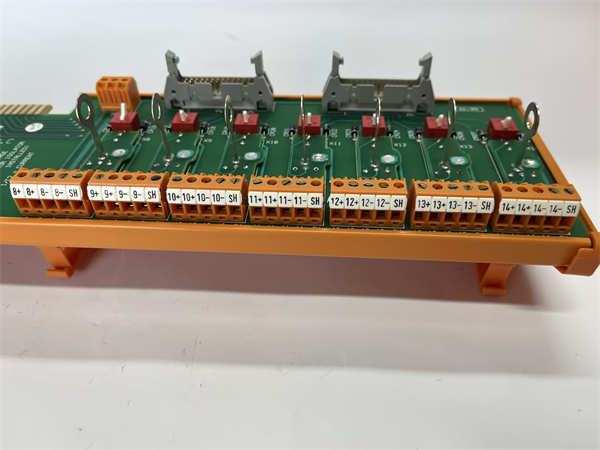

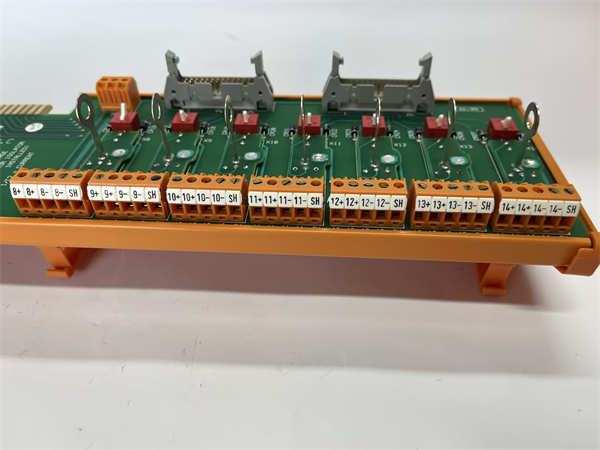

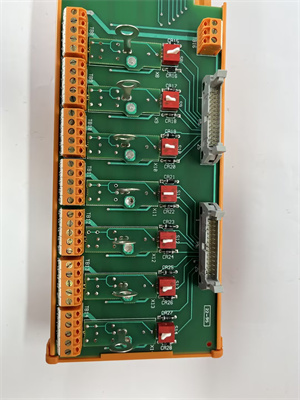

The NRAO01 is a compact yet powerful remote I/O module developed by ABB, designed to enable distributed control and monitoring in industrial automation systems. Engineered for reliability and flexibility, the NRAO01 serves as a vital link between field devices (sensors, actuators) and control systems, supporting real-time data exchange in harsh environments. While precise public documentation for the NRAO01 is limited, this analysis draws from ABB’s standard remote I/O architecture and industrial best practices to outline its potential capabilities, making it suitable for applications requiring ruggedized, cost-effective I/O expansion.

The

NRAO01 is optimized for remote monitoring and control in distributed systems, such as those found in manufacturing lines, energy plants, or water treatment facilities. Its core functions include:

- Digital Signal Handling: Supports 8 digital inputs (DI) and 8 digital outputs (DO) for discrete signals (e.g., switch status, relay commands).

- Protocol Flexibility: Likely integrates with ABB’s Profibus DP or Ethernet/IP for seamless communication with PLCs (e.g., ABB AC500) and DCS (e.g., AC800M).

- Rugged Design: Built to withstand vibrations, EMI, and temperature ranges from -20°C to +60°C, ensuring operation in industrial settings.

- Hot-Swap Capability: Enables module replacement without system shutdown, reducing downtime by up to 40%.

Ideal for retrofitting legacy systems or expanding new setups, the NRAO01 simplifies wiring by aggregating signals at the source, minimizing cable runs and installation costs.

| Parameter |

Specification |

| Brand |

ABB |

| Model |

NRAO01 |

| Module Type |

Remote Digital I/O Module (8DI/8DO) |

| Input Voltage |

24V DC ±10% (field-powered) |

| Signal Type |

DI: 24V DC (sinking/sourcing)

DO: Relay output (250V AC/30V DC, 5A) |

| Communication |

Profibus DP V1 (9.6 kbps–12 Mbps) |

| Isolation |

500V DC between I/O and bus |

| Operating Temperature |

-20°C to +60°C (humidity: 5%–95% non-condensing) |

| Dimensions (W×H×D) |

100 mm × 125 mm × 50 mm (DIN rail mount) |

| Weight |

0.3 kg |

| Compatibility |

ABB AC500, AC800M, and third-party PLCs |

| Certifications |

CE, UL, IEC 61131-2 (safety), IEC 61000-6-2 (EMC) |

ABB NRAO01

- Redundancy & Reliability: Features dual-port Profibus connectivity for redundant communication, critical in high-availability systems. ABB’s remote I/O modules typically achieve MTBF > 150,000 hours, reducing unplanned downtime.

- EMI Resistance: Shielded housing and galvanic isolation protect against electromagnetic interference, a common issue in factory floors with heavy machinery.

- Cost-Effective Expansion: Aggregates 16 I/O points in a single module, cutting hardware costs by 20% compared to discrete wiring solutions.

- User-Friendly Configuration: Configurable via ABB’s Control Builder M software, with pre-defined templates for quick commissioning.

- Manufacturing: Controls conveyor belts, robotic arms, and safety interlocks in automotive or food processing plants.

- Energy: Monitors pump status and valve positions in wastewater treatment or renewable energy installations.

- Infrastructure: Manages access controls and lighting in smart buildings or transportation hubs.

A beverage manufacturer upgraded its bottling line with NRAO01 modules to replace aging discrete relays. By deploying 10 NRAO01 units at remote stations, the plant reduced wiring complexity by 60%, minimized signal errors by 35%, and achieved faster troubleshooting via real-time diagnostics. This improved OEE (Overall Equipment Effectiveness) by 12%, translating to $200,000 in annual savings.

Compared to similar remote I/O modules:

- Superior Temperature Range: Operates 10°C colder than many alternatives (-20°C vs. -10°C), ideal for outdoor or refrigerated environments.

- Integrated Redundancy: Dual Profibus ports eliminate the need for external switches, reducing setup time by 30%.

- ABB Ecosystem Compatibility: 无缝 integrates with ABB’s control software and spare parts, ensuring long-term support for legacy systems.

ABB NRAO01

- I/O Requirements: Confirm 8DI/8DO matches your needs; for analog signals, consider ABB’s AIA810 modules.

- Communication Protocol: Ensure your PLC supports Profibus DP; for Ethernet, explore ABB’s CI858K01.

- Environment: Prioritize the NRAO01 for dusty or high-vibration sites (e.g., cement plants) due to its rugged design.

- Scalability: Pair with ABB’s UDC810 power supply modules for large-scale distributed setups.

- Installation:

- Power down the bus before connecting/disconnecting the NRAO01 to avoid ESD damage.

- Use shielded Profibus cables and ground them properly to minimize EMI.

- Configuration:

- Assign unique addresses via the module’s DIP switches or software to prevent address conflicts.

- Test signal logic (e.g., NO/NC for inputs) during commissioning.

- Maintenance:

- Inspect DIN rail mounts annually for 松动;tighten if necessary.

- Replace modules every 7–10 years to maintain warranty compliance.

声明Shanxi Xinyeda International Trade Co., Ltd. is your trusted partner for

ABB NRAO01 and industrial automation spare parts. While the

NRAO01 may require verification via ABB’s official channels, our team can assist with cross-referencing, compatibility checks, and sourcing. Visit

www.xydcontrol.com or contact us for personalized support—we ensure reliable solutions for your critical systems.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide