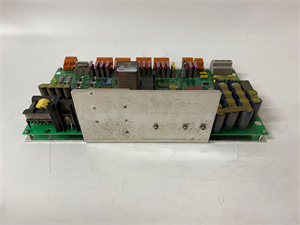

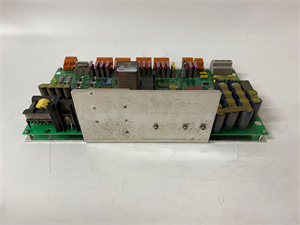

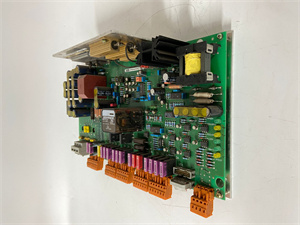

Description

The

ABB KUC720AE is a high-performance

robot controller designed to power ABB’s advanced industrial robotics systems, delivering precise motion control, real-time coordination, and seamless integration with automation ecosystems. As the core brain of ABB’s robot lineup, the

KUC720AE belongs to the

IRC5 controller series, a platform renowned for its reliability and flexibility in manufacturing, logistics, and process industries. This controller serves as the central hub for managing robot arm movements, I/O interactions, and communication with external devices, ensuring deterministic performance in applications ranging from pick-and-place to complex assembly.

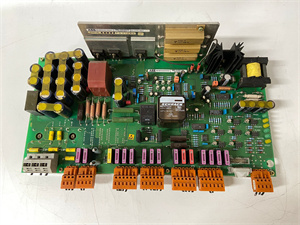

Featuring a compact, fanless design and dual-core processing, the ABB KUC720AE supports up to 16 axes of control, enabling multi-robot coordination and advanced path planning. Its core functions include dynamic collision detection, predictive maintenance algorithms, and compatibility with ABB’s RobotStudio® software for offline programming and simulation. Positioned as a cutting-edge solution for smart factories, the KUC720AE enhances productivity by reducing cycle times, improving repeatability (±0.02 mm accuracy), and enabling rapid deployment of collaborative robots (cobots) alongside human workers.

| Parameter Name |

Parameter Value |

| Product Model |

KUC720AE |

| Manufacturer |

ABB |

| Product Type |

Robot Controller (IRC5 Series) |

| Control Axes |

Up to 16 (6 primary + 10 secondary) |

| Processing Power |

Dual-core ARM Cortex-A9 @ 1 GHz |

| Memory |

2 GB RAM, 8 GB Flash |

| Communication Interfaces |

Ethernet (1 Gbps), Profibus DP, CANopen |

| I/O Channels |

32x DI/DO (expandable via fieldbus modules) |

| Safety Compliance |

ISO 10218-1/2 (Robot Safety Standards) |

| Operating Temperature |

5°C to +45°C (with derating up to +50°C) |

| Dimensions (W×H×D) |

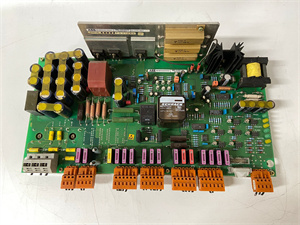

470 mm × 290 mm × 130 mm |

| Mounting Method |

Wall-mounted or integrated into robot cells |

| Certification |

CE, UL, CSA, ISO 13849-1 (PLd) |

KUC720AE

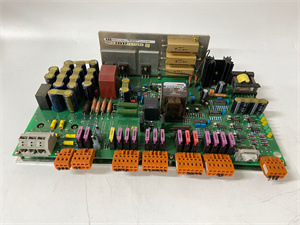

The ABB KUC720AE stands out for its advanced motion control capabilities and industrial-grade durability. Its TrueMove™ and QuickMove™ technologies ensure smooth, vibration-free movements at high speeds, critical for applications requiring precision, such as electronics assembly or pharmaceutical packaging. The controller’s built-in SafeMove™ software provides real-time safety monitoring, allowing robots to operate safely in shared workspaces with humans by limiting speed, force, and position.

A key advantage is the KUC720AE’s compatibility with ABB’s RobotStudio® ecosystem, which enables drag-and-drop programming, virtual commissioning, and simulation of complex robot paths. This reduces programming time by up to 50% compared to traditional methods and minimizes errors during deployment. The controller’s expandable I/O and fieldbus support (e.g., Profibus, Ethernet/IP) allow seamless integration with PLCs, vision systems, and conveyors, creating fully automated production lines.

The fanless design eliminates dust and particle ingress, making the KUC720AE suitable for cleanroom environments (ISO Class 5) and harsh industrial settings with high humidity or vibration. Its modular architecture simplifies maintenance, with hot-swappable components like power supplies and communication modules ensuring minimal downtime.

The ABB KUC720AE is widely deployed across industries that demand high-precision robotic automation. In automotive manufacturing, it controls paint spraying, welding, and final assembly robots, ensuring consistent quality and throughput. In the food and beverage sector, its hygienic design and IP67-rated components make it ideal for packaging, sorting, and palletizing applications, where compliance with strict sanitation standards is essential.

For electronics manufacturing, the KUC720AE enables micro-assembly of components with sub-millimeter precision, supporting the production of semiconductors, PCBs, and consumer electronics. In logistics, it powers autonomous mobile robots (AMRs) and collaborative robots for order picking, kitting, and warehouse management, enhancing flexibility in dynamic fulfillment centers.

The controller also excels in research and development environments, where its open architecture allows integration with custom sensors and algorithms for prototype testing. By addressing challenges like labor shortages, quality control, and process optimization, the KUC720AE helps customers achieve higher OEE (Overall Equipment Effectiveness) and adapt to evolving market demands.

- ABB KUC705AE: A compact variant of the KUC720AE for smaller robots and benchtop applications, supporting up to 8 axes.

- ABB KUKA KR C5: A competitor controller for comparison, though the KUC720AE offers tighter integration with ABB’s robot hardware.

- ABB IRB 1200: A collaborative robot (cobot) that pairs with the KUC720AE for safe human-robot interaction in assembly tasks.

- ABB FlexPendant: A handheld programming device for the KUC720AE, featuring a touchscreen interface and safety buttons.

- ABB IRC5 I/O Module: An expansion module for adding additional DI/DO channels to the KUC720AE-based system.

- ABB RobotWare-OS: The operating system for the KUC720AE, providing firmware updates and new functionality like machine learning integration.

KUC720AE

Pre-installation preparation: Mount the ABB KUC720AE in a stable, grounded control cabinet, ensuring adequate space for cable management. Connect the robot arm’s servo cables, encoder feedback, and Ethernet network using shielded wiring to minimize interference. Use RobotStudio® to configure the robot model, calibration data, and safety zones, ensuring compliance with local regulations.

Maintenance recommendations: Regularly inspect the controller’s status LEDs for fault codes and use RobotStudio®’s diagnostic tools to monitor CPU load, memory usage, and network latency. Clean the cabinet’s ventilation filters monthly to prevent dust buildup, and verify that the operating temperature remains within specified limits. Update the RobotWare-OS firmware quarterly to access new features and security patches. In the event of a hardware failure, replace modules one at a time to isolate issues, using ABB-certified spare parts to maintain system compatibility.

ABB stands behind the KUC720AE with a comprehensive quality assurance program, including rigorous testing for electromagnetic compatibility, shock resistance, and safety compliance. The controller is backed by a standard [X-year] warranty, covering defects in materials and workmanship. ABB’s global service network offers 24/7 technical support, on-site maintenance, and training programs to ensure optimal performance. Customers can leverage ABB’s Remote Services for real-time monitoring of robot health and predictive maintenance insights via the ABB Ability™ platform. With a focus on reliability and innovation, ABB ensures the KUC720AE delivers long-term value as the backbone of intelligent robotic automation.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide