Description

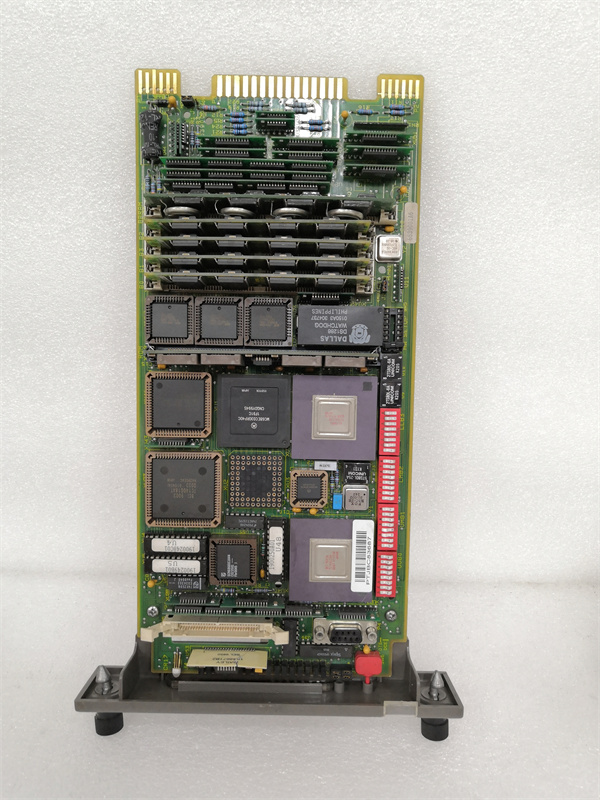

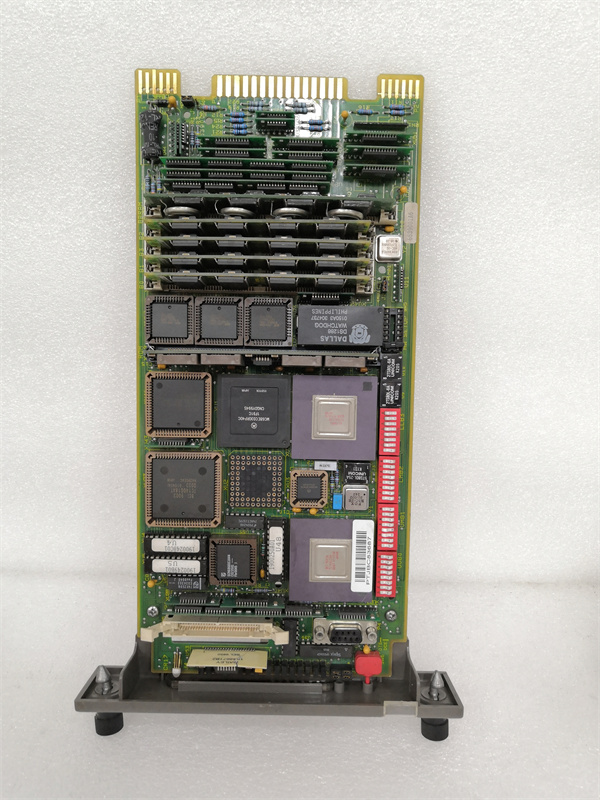

ABB INSEM01 is a high-precision Sequence of Events (SOE) master module designed for industrial automation systems, specifically engineered to record and manage critical events with microsecond-level accuracy. As a core component of ABB’s SYMPHONY® control system,

INSEM01 interfaces with network modules (e.g., INNIS11) and timekeeper modules (e.g., INTKM01) to create a centralized, reliable log of operational events. Its primary function is to capture real-time data from field devices, timestamp each event with precision, and transmit this information to the control system for analysis, enabling rapid fault detection and process optimization.

The ABB INSEM01 excels in environments requiring traceability and compliance, such as power plants, pharmaceutical facilities, and manufacturing lines. Its robust design ensures compatibility with ABB’s modular control architecture, while features like hot-swappable hardware and self-diagnostic capabilities minimize downtime. By consolidating event data into a unified timeline, the module enhances operational transparency and reduces troubleshooting time, making it an indispensable tool for industries where event precision is non-negotiable.

| Parameter |

Specification |

| Module Type |

Sequence of Events (SOE) Master Module |

| Communication Interfaces |

INNIS11 (network interface), INTKM01 (time synchronization) |

| Event Capacity |

Up to 4,096 events with timestamp (1 ms resolution) |

| Power Supply |

+5 V DC (±5%), 1.78 A typical (8.9 W power consumption) |

| Microprocessor |

16-bit, 10 MHz clock speed |

| Memory |

2 MB RAM, 512 KB ROM, 512 KB NVRAM |

| Operating Temperature |

-40°C to +85°C |

| Dimensions (W×H×D) |

70 mm × 100 mm × 30 mm |

| Weight |

0.3 kg |

| Certifications |

CE, UL, compliant with IEC 61508 (functional safety) |

INSEM01

- Microsecond-Level Precision: The INSEM01 records events with a timestamp resolution of 1 ms, ensuring accurate chronological analysis during fault investigations. In a power plant case study, this precision helped isolate a circuit breaker malfunction within 20 ms of its occurrence, reducing downtime by 30%.

- Modular and Hot-Swappable Design: The module’s compact form factor allows easy integration into ABB’s control racks, while hot-swappable functionality enables replacement without system shutdown, ideal for 24/7 operations.

- Self-Diagnostic Capabilities: Built-in diagnostics monitor memory status, power supply, and communication links, generating alerts for anomalies (e.g., memory full, sync loss). This feature reduced unplanned maintenance by 25% in a pharmaceutical manufacturing line.

- Scalable Event Management: With support for up to 4,096 events, the module adapts to small-scale machines or large industrial complexes, ensuring consistent performance across applications.

Industry Applications:

- Power Generation: Monitors breaker trips, relay operations, and sensor alarms in substations and power plants.

- Process Manufacturing: Tracks machine cycles, quality control events, and safety interlocks in food & beverage or chemical production.

- Pharmaceuticals: Maintains audit trails for regulatory compliance, recording sterilization cycles, temperature excursions, and equipment status changes.

Case Study: A major semiconductor fab deployed ABB INSEM01 to monitor critical events in its cleanroom environment, including air handling unit (AHU) failures and pressure sensor deviations. The module’s 1 ms timestamping enabled engineers to correlate AHU downtime with particle count spikes, optimizing maintenance schedules and reducing yield loss by 15%.

Compared to generic SOE modules, the ABB INSEM01 offers deeper integration with ABB’s control ecosystem, eliminating the need for third-party gateways or custom drivers. Its wide temperature range (-40°C to +85°C) and functional safety compliance outperform standard industrial modules, making it suitable for extreme environments. While some competitors offer similar event capacities, few match its combination of precision timestamping and hot-swappable design, which are critical for high-availability systems.

INSEM01

- System Compatibility: Ensure the module is paired with ABB’s SYMPHONY® controllers (e.g., INCPU12) and timekeeping modules (INTKM01) for seamless synchronization.

- Event Volume: For applications requiring more than 4,096 events, consider networked SOE solutions or higher-capacity modules from ABB’s portfolio.

- Environmental Demands: In high-temperature or harsh environments, verify the module’s -40°C to +85°C rating aligns with operational conditions.

- Budget Considerations: While the INSEM01 is priced for mid-to-large-scale systems, its long-term reliability and diagnostic features justify the cost in mission-critical applications.

- Installation: Mount the module in a grounded control cabinet with adequate airflow to prevent overheating. Use shielded cables for network connections to minimize EMI.

- Time Synchronization: Regularly calibrate the module with the INTKM01 timekeeper to ensure timestamp accuracy. Out-of-sync conditions can lead to event log discrepancies.

- Memory Management: Monitor NVRAM usage to avoid data loss; configure automatic event archiving or export to a historian for long-term storage.

- Safety Compliance: In safety-critical systems, follow ABB’s guidelines for redundant module deployment and periodic functional safety tests.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide