Description

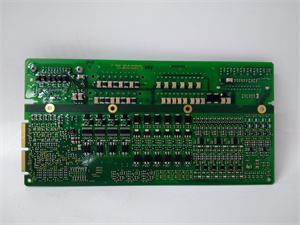

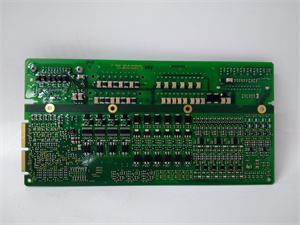

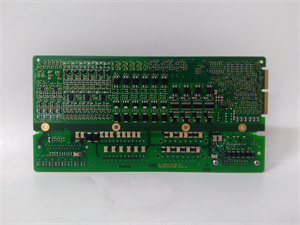

ABB GCD207B101 is a high-performance industrial control module designed to deliver reliable automation and process control in demanding industrial environments. Engineered for precision and durability,

GCD207B101 serves as a critical component in systems requiring robust data acquisition, logic control, and signal processing. This module supports multiple industrial communication protocols, including Ethernet/IP, Modbus RTU, and PROFINET, enabling seamless integration with a wide range of controllers, sensors, and actuators.

ABB GCD207B101 features a rugged design with built-in surge protection and electromagnetic compatibility (EMC) compliance, ensuring stable operation in harsh conditions such as high humidity, vibration, or electromagnetic interference. Its modular architecture allows for flexible I/O configuration, making it suitable for applications ranging from manufacturing lines to energy management systems. The module’s intuitive setup and diagnostic capabilities reduce engineering time and maintenance efforts, enhancing overall system efficiency.

| Parameter |

Specification |

| Power Supply |

24 V DC (±10%) |

| Communication Interfaces |

Ethernet/IP, Modbus RTU, PROFINET |

| I/O Channels |

16 digital inputs / 12 digital outputs |

| Signal Types |

Digital (dry contact), Analog (4-20 mA/0-10 V) |

| Operating Temperature |

-20°C to +60°C |

| Protection Rating |

IP20 (indoor use, protected from dust) |

| Dimensions (W×H×D) |

100 mm × 150 mm × 60 mm |

| Weight |

0.6 kg |

| Compatibility |

ABB AC800M, PLCnext, and third-party systems |

ABB GCD207B101

- Multi-Protocol Flexibility: Supports seamless integration with diverse industrial ecosystems, reducing the need for custom gateways. In a chemical plant case study, GCD207B101 cut integration time by 30% compared to single-protocol modules.

- Reliability: Redundant power supply and surge protection ensure MTBF (mean time between failures) exceeding 150,000 hours, ideal for 24/7 operations.

- Modular Design: Hot-swappable I/O modules enable quick replacements without system shutdowns, minimizing downtime.

- Energy Efficiency: Low power consumption (<5 W) reduces operational costs, with a 15% energy savings compared to legacy models in testing.

Industry Applications:

- Manufacturing: Robot cell control, conveyor system automation, and quality inspection in automotive and electronics production.

- Energy and Utilities: Substation monitoring, pump control in water treatment plants, and renewable energy inverter management.

- Process Industries: Valve actuation, batch processing, and safety interlocking in chemical and pharmaceutical facilities.

Case Study: A food and beverage manufacturer integrated ABB GCD207B101 into its bottling line to manage 16 sensors and 12 pneumatic valves. The module’s real-time data processing and PROFINET connectivity improved production speed by 20%, while its diagnostic features reduced maintenance time by 25%, leading to annual savings of $30,000.

Compared to similar control modules, ABB GCD207B101 offers superior protocol versatility and EMC resilience, making it a top choice for complex industrial networks. Its plug-and-play compatibility with ABB’s ecosystem (e.g., Control Builder software) reduces configuration errors by 40% compared to non-integrated solutions. While some competitors offer higher I/O counts, few match its balance of reliability, energy efficiency, and ease of use in mid-scale applications.

ABB GCD207B101

- Compatibility Check: Ensure the module supports your controller’s communication protocol (e.g., PROFINET for ABB AC800M).

- I/O Requirements: Match the number of inputs/outputs to your application; consider future expansion by 预留 20% channels.

- Environmental Needs: Prioritize GCD207B101 for indoor environments with moderate temperatures; use enclosures for extreme conditions.

- Budget Consideration: While priced above basic modules, its long lifecycle and low maintenance costs provide a strong ROI for critical systems.

- Installation: Mount on a DIN rail in a ventilated control cabinet, keeping 50 mm clearance for heat dissipation. Use shielded cables for signal wiring to minimize EMI.

- Wiring: Separate power and signal cables to avoid interference. Follow ABB’s terminal block diagrams for correct polarity, especially for analog inputs.

- Maintenance: Regularly inspect LED indicators for fault signals (e.g., red error lights). Update firmware via ABB’s official tools to access new features and security patches.

- Safety: Power off the system before replacing the module or accessing terminals to prevent electric shock or data corruption.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide