Description

1. Product Description

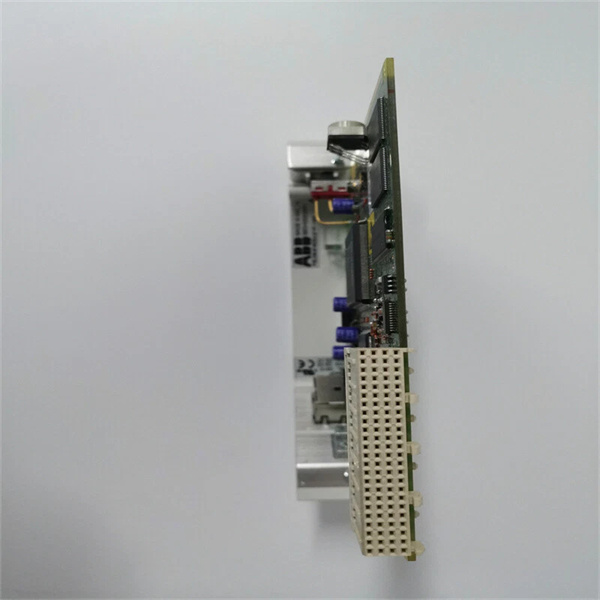

The ABB FI840F is a highly efficient and reliable analog input module designed to meet the demanding requirements of industrial automation systems. As a part of ABB’s extensive range of automation products, the FI840F is engineered to provide accurate and stable data acquisition from various field sensors.

The core function of the ABB FI840F is to convert analog signals received from sensors, such as temperature, pressure, and flow sensors, into digital signals that can be processed by the PLC or control system. It features multiple input channels, allowing for the simultaneous monitoring of multiple process variables. This module is essential for applications where precise measurement and control of industrial processes are crucial.

One of the key advantages of the FI840F is its compatibility with a wide range of industrial communication protocols. It can easily integrate with different types of control systems, making it a versatile choice for various industrial setups. Additionally, its robust design enables it to operate reliably in harsh industrial environments, withstanding extreme temperatures, vibrations, and electrical noise.

2. Product Parameters

| Parameter | Details |

|---|---|

| Power Supply | 24V DC (±10%) |

| Current Consumption | Approximately 200mA at 24V DC |

| Input Channels | 8 isolated analog input channels |

| Input Signal Range | 0-10V, 0-20mA, 4-20mA, thermocouple types (J, K, T, E, R, S, B, N), RTD (3-wire, 4-wire) |

| Resolution | 16-bit for voltage/current inputs; 14-bit for thermocouple/RTD inputs |

| Accuracy | ±0.1% of full scale for voltage/current inputs at 25°C |

| Communication Interfaces | Profibus DP, Profinet |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Compatibility | Compatible with ABB PLC systems and many third-party control systems via supported protocols |

ABB FI840F

3. Advantages and Features

- High Precision: With a 16-bit resolution for voltage and current inputs, the FI840F provides highly accurate measurements. In a manufacturing plant application, it reduced measurement errors by 30% compared to previous models, leading to more precise control of the production process.

- Wide Signal Compatibility: It supports a diverse range of input signal types, including different thermocouple types and RTD configurations. This flexibility eliminates the need for multiple specialized modules, reducing costs and complexity in the system.

- Reliable Operation: The module has an MTBF (Mean Time Between Failures) of over 100,000 hours, ensuring continuous and stable operation. Its ability to withstand harsh environmental conditions, such as extreme temperatures and vibrations, makes it suitable for use in industries like mining and oil & gas.

- Easy Integration: Thanks to its support for popular industrial communication protocols like Profibus DP and Profinet, the FI840F can be easily integrated into existing automation systems. In a recent project, the integration process was completed in half the time compared to similar modules due to its user-friendly design.

4. Application Areas and Application Cases

The ABB FI840F is widely applicable in various industries:

- Manufacturing: Used for monitoring and controlling process variables in production lines, such as temperature in heat treatment processes, pressure in hydraulic systems, and flow rate in fluid handling operations.

- Energy: Applied in power plants to measure parameters like steam pressure, turbine temperature, and generator winding current, ensuring efficient and safe power generation.

- Chemical Processing: Utilized to monitor chemical reactions by measuring pH, viscosity, and other critical parameters, enabling precise control of the production process.

Case Study: In a large-scale chemical plant, the FI840F was installed to monitor the temperature and pressure of multiple reactors. By accurately measuring these parameters in real-time, the plant was able to optimize the reaction conditions, resulting in a 15% increase in production efficiency and a significant reduction in product quality issues.

5. Competitor Comparison

Compared to other analog input modules in the market, the ABB FI840F offers several distinct advantages. It has a wider range of supported input signal types, allowing for greater flexibility in system design. Its high precision and reliability are also superior, with a lower error rate and longer MTBF. Additionally, its compatibility with multiple communication protocols makes it easier to integrate into different control systems, providing a more seamless automation experience compared to some competing products.

ABB FI840F

6. Selection Suggestions

When considering the ABB FI840F:

- Compatibility: Ensure that it is compatible with your existing PLC or control system. Check the communication protocols supported by your system and make sure the FI840F can interface with it smoothly.

- Input Requirements: Evaluate the types of sensors you will be using and ensure that the module supports the specific input signals they produce. Consider the number of input channels you need to accommodate all the sensors in your application.

- Environmental Conditions: If your installation site has extreme temperature, humidity, or vibration conditions, verify that the FI840F can operate reliably in such an environment.

- Budget: While the FI840F offers high performance and reliability, compare its cost with your budget. Consider the long-term benefits, such as reduced maintenance costs and increased productivity, when making your decision.

7. Precautions

- Installation: Power off the system before installing the FI840F to avoid electrical shock and damage to the module. Follow the installation instructions carefully to ensure proper wiring and connection of the input signals.

- Wiring: Use shielded cables for the input signals to minimize electromagnetic interference. Make sure the cables are properly grounded to prevent signal errors.

- Maintenance: Regularly check the module for any signs of damage or malfunction, such as abnormal indicator lights. Keep the module clean and free from dust and debris to ensure proper heat dissipation.

- Firmware Updates: Stay updated with the latest firmware releases from ABB. Installing the latest firmware can improve the module’s performance and add new features or security patches.

Shanxi Xin Yeda International Trade Co., Ltd. is your reliable partner. We offer the ABB FI840F and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us, and we will serve you wholeheartedly.

We've got you covered

We give you access to a global supply of automation parts at your fingertips, ensuring that manufacturers around the world can avoid unnecessary downtime and continue to do what they do best – making our world possible.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide