Description

The

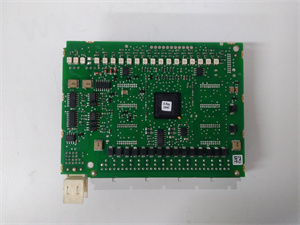

ABB DO880-1 is a high-performance digital output module designed for industrial automation systems, specifically engineered to integrate seamlessly with ABB’s AC 800M control platform. As part of the robust DO880 series, this module serves as a critical interface between the control system and field devices, enabling precise and reliable switching of digital signals. The

ABB DO880-1 is built to handle demanding industrial environments, providing 16 isolated digital output channels that support both relay and solid-state switching technologies. Its design prioritizes safety, scalability, and ease of integration, making it an ideal choice for applications requiring deterministic control in sectors such as manufacturing, energy, and process industries.

This module acts as a bridge for converting control system commands into physical actions, such as activating motors, valves, or alarms. The ABB DO880-1 features advanced diagnostics and fault-handling capabilities, ensuring continuous operation and minimizing downtime. With its modular architecture, it allows for flexible configuration within distributed control systems (DCS), enhancing system adaptability to varying process requirements. By combining high-speed response times with rugged construction, the ABB DO880-1 delivers consistent performance, making it a cornerstone for reliable automation solutions that prioritize both efficiency and safety.

| Parameter Name |

Parameter Value |

| Product Model |

DO880-1 |

| Manufacturer |

ABB |

| Product Type |

Digital Output Module |

| Output Channels |

16 isolated channels |

| Output Type |

Relay or solid-state (configurable) |

| Voltage Range |

24 V DC / 120-230 V AC |

| Maximum Current per Channel |

2 A (resistive load) |

| Communication Protocol |

PROFIBUS DP, Ethernet/IP (via gateway) |

| Operating Temperature |

-40°C to +70°C |

| Dimensions (W x H x D) |

100 mm x 160 mm x 80 mm |

| Installation Method |

Rail-mounted (DIN rail compatible) |

| Certification |

CE, UL, CSA, ATEX (for hazardous areas) |

ABB DO880-1

The ABB DO880-1 stands out for its combination of versatility and durability, tailored to meet the complex demands of modern industrial control systems. One of its key features is the dual-mode output capability, allowing users to select between relay and solid-state outputs based on the specific requirements of their application. This flexibility ensures optimal performance whether driving inductive loads in motor control centers or low-power signals in instrumentation systems.

Reliability is further enhanced through built-in surge protection and short-circuit detection on each channel, safeguarding both the module and connected devices from electrical faults. The ABB DO880-1 also incorporates hot-swappable functionality, enabling maintenance or replacement without powering down the entire system—a critical advantage for minimizing production interruptions in continuous processes.

Additionally, the module’s advanced diagnostics provide real-time status feedback, including channel-level fault indication and voltage monitoring. This proactive approach to system health management allows for rapid troubleshooting and reduces mean time to repair (MTTR). Compatibility with ABB’s Control Builder M software streamlines configuration and commissioning, while its adherence to international standards ensures seamless integration into global automation setups.

ABB DO880-1

The ABB DO880-1 is widely applicable across industries that rely on precise digital control, making it a staple in manufacturing, oil and gas, water treatment, and power generation systems. In manufacturing plants, the module excels at managing conveyor systems, robotic arms, and assembly line actuators, where reliable switching is essential for maintaining production throughput. In process industries, it is used to control valves, dampers, and pumps in chemical processing or refining applications, ensuring safe and efficient operation even in harsh environments.

For hazardous area installations, the ATEX-certified ABB DO880-1 provides the necessary safety credentials to operate in explosive atmospheres, such as those found in petrochemical facilities or gas storage sites. Its wide voltage range also makes it suitable for global deployments, accommodating varying regional power standards without additional hardware modifications. Whether used in a standalone PLC system or as part of a distributed control network, the module’s scalability and robust design make it a trusted choice for both small-scale machines and large-scale industrial complexes.

- ABB DO880-2: A variant with enhanced current capacity (3 A per channel) for heavy-duty loads, ideal for industrial machinery requiring higher power switching.

- ABB DI880: Complementary digital input module with 16 channels, designed for seamless integration alongside the DO880 series in mixed I/O systems.

- ABB AO880: Analog output module from the same family, offering 8 channels for continuous control signals in process automation.

- ABB AC 800M Controller: The core control platform for the DO880 series, providing processing power and communication interfaces for centralized automation.

- ABB TB880 Terminal Block: Dedicated terminal block for the DO880 series, simplifying wiring and improving mechanical stability in panel installations.

Pre-installation preparation: Ensure the control system is powered off and the DIN rail is securely mounted in a grounded enclosure. Verify that the voltage supply matches the ABB DO880-1’s specifications (24 V DC or 120-230 V AC) and that all field devices are properly isolated. Use the provided mounting brackets to attach the module to the DIN rail, ensuring adequate spacing for heat dissipation. Connect the communication bus (PROFIBUS DP or Ethernet/IP gateway) and power supply cables according to the wiring diagram in the product manual.

Maintenance recommendations: Regularly inspect the module for physical damage or loose connections, especially in high-vibration environments. Use the control system’s diagnostic tools to monitor channel status and identify any faulty outputs. If a channel failure is detected, replace the module or individual relay cartridges (for relay-type outputs) while observing hot-swap procedures to avoid system disruptions. Periodically clean the module’s ventilation slots to prevent dust accumulation, which can affect thermal performance. Annual calibration of the module’s output signals is recommended for critical applications to ensure accuracy and compliance with operational standards.

ABB stands behind the DO880-1 with a comprehensive quality assurance program, ensuring each module meets rigorous industry standards for reliability and performance. The product is backed by a standard warranty covering defects in materials and workmanship, with extended warranty options available for enhanced protection. ABB’s global network of technical support and service centers provides 24/7 assistance for troubleshooting, configuration, and maintenance, ensuring minimal downtime and rapid resolution of issues. Customers can access detailed documentation, software updates, and training resources through ABB’s digital platforms, empowering them to optimize the module’s performance throughout its lifecycle. The ABB DO880-1 is designed for long-term durability, with continuous firmware support to adapt to evolving automation protocols and industry requirements, making it a future-proof investment for industrial control systems.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.

Continue Searching

We're here when you need us

What happens next?

- 1. Email confirmation

You will get an email confirming that we have received your enquiry.

- 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition.

- 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty on all components

Full 12-month warranty on all components Dedicated after-sales support

Dedicated after-sales support Same-day dispatch on 1000s of parts

Same-day dispatch on 1000s of parts All units are fully tested

All units are fully tested

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide